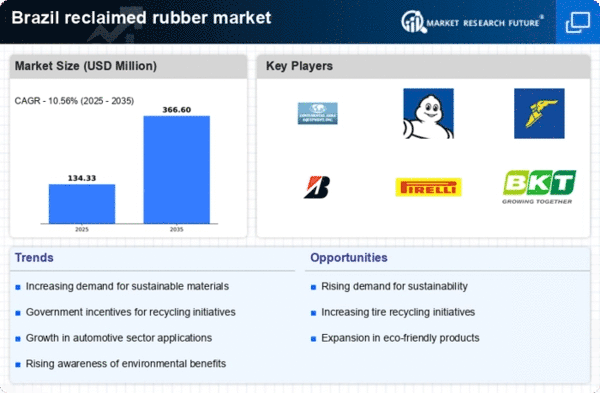

The reclaimed rubber market in Brazil is characterized by a competitive landscape that is increasingly shaped by sustainability initiatives and technological advancements. Key players such as Continental AG (DE), Michelin (FR), and Goodyear Tire & Rubber Company (US) are actively pursuing strategies that emphasize innovation and environmental responsibility. These companies are not only focusing on enhancing their product offerings but are also investing in research and development to improve the quality and performance of reclaimed rubber. This collective emphasis on sustainability and innovation appears to be a significant driver of growth within the market, fostering a competitive environment that encourages differentiation through advanced technologies and eco-friendly practices.In terms of business tactics, companies are increasingly localizing manufacturing to reduce costs and improve supply chain efficiency. This approach is particularly relevant in Brazil, where logistical challenges can impact operational effectiveness. The market structure is moderately fragmented, with several key players holding substantial market shares. The influence of these major companies is profound, as they set industry standards and drive competitive dynamics through their strategic initiatives.

In October Michelin (FR) announced a partnership with a Brazilian startup focused on developing advanced recycling technologies for rubber. This collaboration aims to enhance the sustainability of Michelin's supply chain while also positioning the company as a leader in innovative recycling solutions. The strategic importance of this partnership lies in its potential to significantly reduce waste and improve the overall environmental footprint of rubber production, aligning with global sustainability goals.

In September Goodyear Tire & Rubber Company (US) launched a new line of tires incorporating reclaimed rubber sourced from local Brazilian suppliers. This initiative not only supports local economies but also demonstrates Goodyear's commitment to sustainable practices. The strategic move is likely to enhance brand loyalty among environmentally conscious consumers and strengthen Goodyear's market position in Brazil.

In August Continental AG (DE) expanded its operations in Brazil by investing in a new facility dedicated to the production of high-performance reclaimed rubber. This investment reflects Continental's strategy to increase its production capacity and meet the growing demand for sustainable materials. The establishment of this facility is expected to bolster Continental's competitive edge by enabling faster delivery times and improved product availability in the region.

As of November the competitive trends in the reclaimed rubber market are increasingly defined by digitalization, sustainability, and the integration of artificial intelligence in production processes. Strategic alliances among key players are shaping the landscape, fostering innovation and collaboration. The shift from price-based competition to a focus on technological advancement and supply chain reliability is evident, suggesting that future competitive differentiation will hinge on the ability to innovate and adapt to changing market demands.