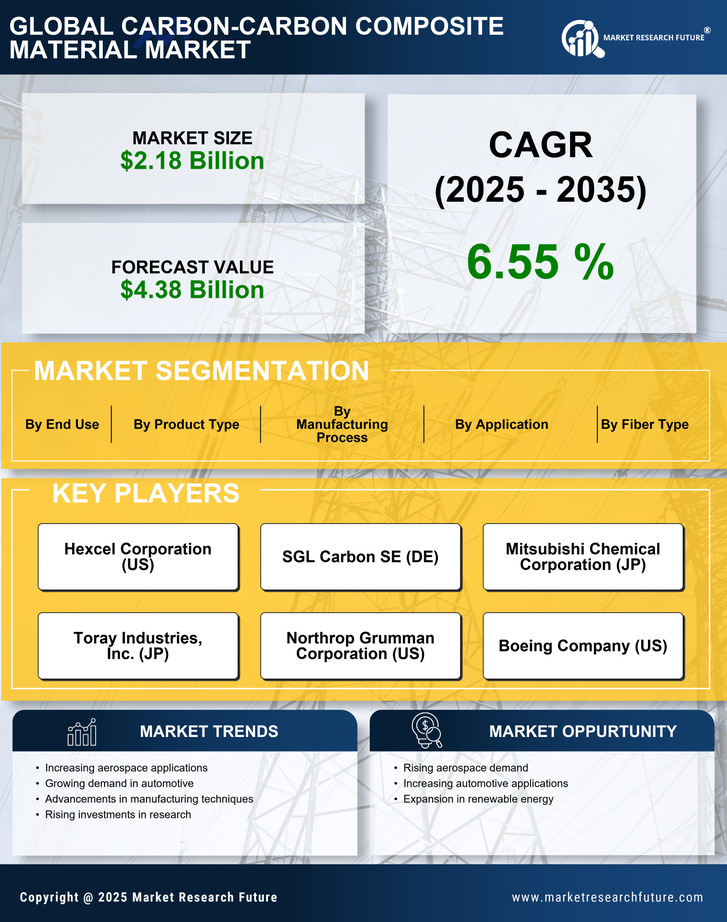

Growing Demand in Automotive Sector

The automotive sector is increasingly recognizing the benefits of carbon-carbon composites, contributing to the expansion of the Carbon-carbon Composite Material Market. With the automotive industry focusing on lightweight materials to improve fuel efficiency and reduce emissions, carbon-carbon composites are becoming a viable option. The market for these materials in automotive applications is projected to grow at a rate of 4% annually. This growth is driven by the need for high-performance components that can withstand extreme conditions, such as brake systems and engine parts. As automotive manufacturers continue to innovate and seek sustainable solutions, the demand for carbon-carbon composites is likely to rise, thereby enhancing the Carbon-carbon Composite Material Market.

Rising Focus on Aerospace Efficiency

The aerospace industry is placing a heightened emphasis on efficiency and performance, which is positively impacting the Carbon-carbon Composite Material Market. As airlines and manufacturers strive to reduce operational costs and improve fuel efficiency, the use of lightweight materials like carbon-carbon composites is becoming increasingly prevalent. The market is anticipated to grow at a rate of 5.5% as aerospace companies adopt these materials for components such as heat shields and structural parts. The ability of carbon-carbon composites to withstand high temperatures and provide structural integrity under extreme conditions makes them indispensable in modern aerospace applications. This trend underscores the critical role of carbon-carbon composites in enhancing the overall efficiency of the aerospace sector.

Advancements in Manufacturing Techniques

Innovations in manufacturing techniques are significantly influencing the Carbon-carbon Composite Material Market. The development of advanced processing methods, such as chemical vapor infiltration and resin transfer molding, has improved the efficiency and cost-effectiveness of producing carbon-carbon composites. These advancements enable manufacturers to create complex geometries and enhance material properties, which are crucial for high-performance applications. As a result, the market is expected to witness a compound annual growth rate of around 6% over the next few years. The ability to produce high-quality composites at lower costs is likely to attract a broader range of industries, further propelling the growth of the Carbon-carbon Composite Material Market.

Emerging Applications in Renewable Energy

The Carbon-carbon Composite Material Market is witnessing emerging applications in the renewable energy sector, particularly in wind energy and solar power. The unique properties of carbon-carbon composites, such as high strength-to-weight ratios and resistance to environmental degradation, make them suitable for various components in renewable energy systems. For instance, wind turbine blades and solar panel supports are increasingly being manufactured using these materials. The renewable energy market is expected to grow significantly, with projections indicating a compound annual growth rate of 7% in the coming years. This growth presents a substantial opportunity for the Carbon-carbon Composite Material Market, as the demand for durable and efficient materials in renewable energy applications continues to rise.

Increasing Applications in Defense Sector

The Carbon-carbon Composite Material Market is experiencing a notable surge in demand due to its increasing applications in the defense sector. These materials are favored for their exceptional thermal resistance and lightweight properties, making them ideal for aerospace and military applications. The defense industry is projected to invest heavily in advanced materials, with estimates suggesting a growth rate of approximately 5% annually. This trend indicates a robust market potential for carbon-carbon composites, as they are utilized in missile components, aircraft structures, and other critical defense systems. The emphasis on enhancing performance while reducing weight aligns with the strategic goals of defense manufacturers, thereby driving the growth of the Carbon-carbon Composite Material Market.