Increasing Regulatory Standards

The Cold Insulation Material Market is influenced by the rising regulatory standards aimed at improving energy efficiency and reducing greenhouse gas emissions. Governments worldwide are implementing stringent regulations that mandate the use of high-performance insulation materials in construction and industrial applications. These regulations not only promote energy conservation but also encourage the adoption of cold insulation materials that comply with environmental standards. As a result, manufacturers are compelled to innovate and produce materials that meet these requirements, thereby driving growth in the Cold Insulation Material Market. The ongoing evolution of regulatory frameworks is expected to create new opportunities for market players.

Rising Demand for Energy Efficiency

The Cold Insulation Material Market is experiencing a notable surge in demand driven by the increasing emphasis on energy efficiency across various sectors. Industries such as refrigeration, HVAC, and construction are actively seeking materials that minimize energy loss. According to recent data, energy-efficient buildings can reduce energy consumption by up to 30%, which significantly boosts the demand for cold insulation materials. This trend is further supported by the growing awareness of climate change and the need for sustainable practices. As companies strive to meet energy efficiency standards, the Cold Insulation Material Market is likely to see continued growth, as these materials play a crucial role in achieving energy-saving goals.

Expansion of Industrial Applications

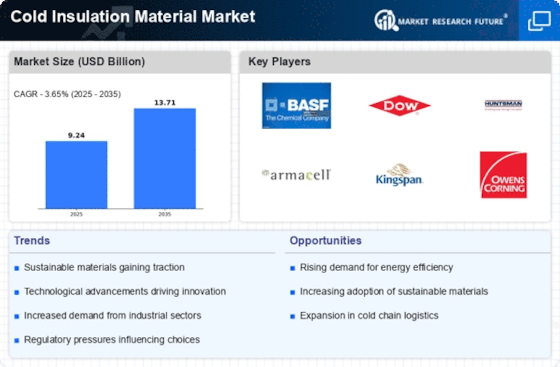

The Cold Insulation Material Market is witnessing an expansion in its applications across various industrial sectors. Industries such as oil and gas, chemical processing, and food and beverage are increasingly utilizing cold insulation materials to maintain temperature-sensitive processes. For instance, the oil and gas sector relies heavily on these materials to ensure the integrity of pipelines and storage tanks. The market data indicates that the industrial segment accounts for a significant share of the overall cold insulation market, with projections suggesting a compound annual growth rate of around 5% over the next few years. This diversification of applications is likely to enhance the market's resilience and growth potential.

Growing Awareness of Environmental Impact

The Cold Insulation Material Market is increasingly shaped by the growing awareness of environmental impacts associated with energy consumption. Consumers and businesses alike are becoming more conscious of their carbon footprints, leading to a shift towards sustainable insulation solutions. This trend is reflected in the rising demand for eco-friendly cold insulation materials that minimize environmental harm. Market data suggests that the demand for sustainable insulation products is projected to grow at a rate of 6% annually. As stakeholders prioritize sustainability, the Cold Insulation Material Market is likely to experience a transformation, with a focus on materials that align with environmental goals.

Technological Innovations in Insulation Materials

Technological advancements are playing a pivotal role in shaping the Cold Insulation Material Market. Innovations in material science have led to the development of advanced insulation products that offer superior thermal performance and durability. For example, the introduction of aerogel-based insulation materials has revolutionized the market by providing exceptional insulation properties with reduced thickness. This trend is expected to drive the adoption of cold insulation materials in various applications, including cryogenic storage and transportation. As manufacturers continue to invest in research and development, the Cold Insulation Material Market is likely to benefit from enhanced product offerings that meet the evolving needs of consumers.

.png)