Market Trends

Key Emerging Trends in the Construction Lubricants Market

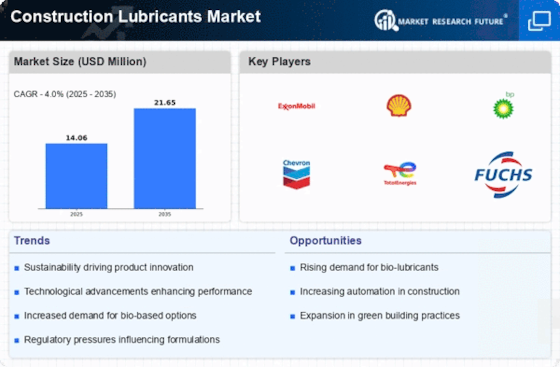

Construction Lubricants Market trends are changing the industry. Construction lubricants are in demand as the construction sector grows globally. These lubricants improve the efficiency and lifespan of construction machines. Market trends favor sustainable lubricants.

With environmental awareness developing, construction businesses are using biodegradable, low toxicity lubricants. This move supports the industry's sustainable practices and regulatory needs to reduce construction's environmental impact. Demand for high performance lubricants that can resist building site conditions is also rising. Construction machinery works in dusty, dirty, and hot conditions.

Another trend is lubricant compositions incorporating more technology. Smart lubricants with sensors and monitoring capabilities help construction businesses track machine performance in real time. This permits predictive maintenance, preventing costly breakdowns and extending construction machinery lifespan. IoT (Internet of Things) technology in lubricants helps construction businesses manage maintenance schedules, decrease downtime, and boost operational efficiency.

Regional dynamics also affect construction lubricants market trends. These lubricants are in high demand in Asia-Pacific and Middle Eastern developing economies with strong construction sectors. Rapid urbanization, infrastructure development, and government attempts to enhance construction projects are driving market expansion in these regions. However, strict environmental restrictions and the construction industry's dedication to greener practices are driving a transition toward more sustainable and technologically advanced lubricants in established markets in North America and Europe.

As construction organizations seek operational excellence and cost-effectiveness, outsourcing lubrication services is growing. Lubrication management outsourcing lets construction organizations focus on their main activities while benefiting from lubrication experts. These businesses provide customized lubricant selection, application, and maintenance to improve construction machinery efficiency and reliability.

The Construction Lubricants Market is changing due to environmental concerns, technical advances, regional dynamics, and a shift toward outsourcing lubrication services. The market is changing due to the industry's focus on sustainability and smart technologies in lubricants. The demand for specialty lubricants that improve equipment performance and operational efficiency is likely to drive market expansion as construction activities rise worldwide."

Leave a Comment