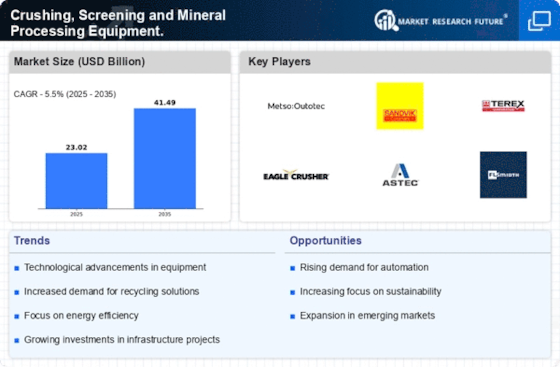

Leading market players are investing heavily in the research and development in order to spread their product lines, which will help the Crushing, Screening and Mineral Processing Equipment market grow even more. Market players are also undertaking a variety of strategic activities to spread their global footprint, with important market developments including higher investments, new product launches, contractual agreements, mergers and acquisitions, and collaboration with other organizations. To spread and survive in a more competitive and rising market climate, the Crushing, Screening and Mineral Processing Equipment industry must offer cost-effective items.

Manufacturing locally to minimize the operational costs is one of the key business tactics used by the manufacturers in the global Crushing, Screening and Mineral Processing Equipment industry to benefit clients and increase the market sector. In recent years, the Crushing, Screening and Mineral Processing Equipment industry has offered some of the most significant advantages to the construction industry.

Major players in the Crushing, Screening and Mineral Processing Equipment market, including Terex Corporation, Metso Corporation, Sandvik AB, Mccloskey International, Astec Industries, Inc., Kleemann GMBH, Eagle Crusher, Screen Machine Industries, Caterpillar Inc., and Rubble Master, and others, are attempting to increase market demand by investing in the research and development operations.

Sandvik AB, a Swedish multinational engineering company that specializes in mining and rock excavation, metal cutting, and materials technology. Sandvik is known for its commitment to research and development. The company continually invests in innovation to develop cutting-edge products and solutions for its customers. Sandvik has embraced digitalization and Industry 4.0 concepts in its operations. It offers digital solutions that enhance productivity, efficiency, and safety for its customers. Sandvik is a publicly traded company listed on the Stockholm Stock Exchange (Nasdaq Stockholm). It has a strong financial track record and is recognized as a leader in its industry sectors.

In August 2023, Sandvik AB acquired the mining business of Schenck Process, a German industrial machinery manufacturing company. This acquisition strengthens Sandvik's position in the mining equipment market and expands its portfolio of products and services for the mining industry, including crushing, screening and mineral processing equipment.

Metso Outotec is a Finnish multinational corporation specializing in providing technologies, equipment, and the services for the mining, aggregates, recycling, and metal refining industries. The company was formed through the merger of Metso Corporation and Outotec Oyj in 2020. Metso Outotec is committed to innovation and investing in research and development to create advanced technologies and solutions for its customers. This includes digitalization and the development of Industry 4.0 solutions.

In July Metso Outotec acquired McCloskey International, a Canadian manufacturer of mobile crushing and screening equipment.

This acquisition expands Metso Outotec's product portfolio and geographic reach in the mobile crushing and screening market.