Growth in Automotive Electronics

The automotive sector is undergoing a transformation, with an increasing reliance on electronic components, which is significantly impacting the Dielectric Etcher Market. The rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) necessitates the use of sophisticated semiconductor technologies, which in turn drives the demand for precise dielectric etching solutions. As of 2025, the automotive electronics market is projected to grow substantially, with a focus on enhancing vehicle performance and safety features. This growth is likely to create new opportunities for dielectric etching manufacturers, as they develop specialized equipment to meet the unique requirements of automotive applications. The integration of advanced etching technologies into automotive electronics is expected to enhance the functionality and reliability of vehicles, thereby further propelling the Dielectric Etcher Market.

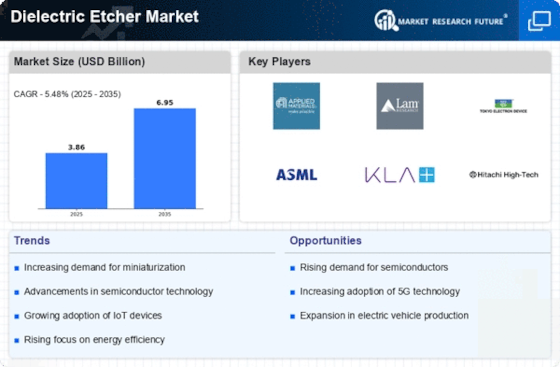

Rising Demand for Semiconductors

The Dielectric Etcher Market is experiencing a notable surge in demand for semiconductors, driven by the proliferation of electronic devices and the Internet of Things. As industries increasingly rely on advanced semiconductor technologies, the need for precise etching processes becomes paramount. In 2025, the semiconductor market is projected to reach approximately 600 billion USD, indicating a robust growth trajectory. This demand directly influences the Dielectric Etcher Market, as manufacturers seek efficient and reliable etching solutions to meet the stringent requirements of semiconductor fabrication. The increasing complexity of semiconductor designs necessitates advanced dielectric etching techniques, further propelling the market forward. Consequently, the Dielectric Etcher Market is poised to benefit from this escalating demand, as companies invest in innovative etching technologies to enhance production capabilities.

Increasing Focus on Miniaturization

The trend towards miniaturization in electronics is a significant driver for the Dielectric Etcher Market. As devices become smaller and more compact, the demand for precise etching techniques that can accommodate intricate designs is escalating. This miniaturization trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where space constraints necessitate advanced manufacturing processes. In 2025, the market for miniaturized electronic components is projected to expand, thereby increasing the demand for dielectric etching solutions that can deliver high precision at reduced scales. Consequently, manufacturers are compelled to adopt advanced etching technologies to meet these evolving requirements, positioning the Dielectric Etcher Market for sustained growth. The ability to produce smaller, more efficient components will likely enhance the overall performance of electronic devices, further driving market demand.

Expansion of Renewable Energy Technologies

The growing emphasis on renewable energy technologies is emerging as a pivotal driver for the Dielectric Etcher Market. As the world shifts towards sustainable energy solutions, the demand for advanced photovoltaic cells and energy storage systems is increasing. These technologies often require sophisticated dielectric etching processes to achieve the necessary efficiency and performance standards. In 2025, the renewable energy sector is expected to witness substantial growth, with investments in solar and wind energy technologies reaching new heights. This expansion is likely to create a corresponding demand for dielectric etching equipment tailored for the production of high-performance solar cells and batteries. As manufacturers adapt to these trends, the Dielectric Etcher Market stands to benefit from the integration of etching technologies that support the development of innovative renewable energy solutions.

Technological Innovations in Etching Equipment

Technological advancements play a crucial role in shaping the Dielectric Etcher Market. The introduction of innovative etching equipment, characterized by enhanced precision and efficiency, is transforming manufacturing processes. For instance, the development of atomic layer etching (ALE) technology allows for unprecedented control over etching processes, enabling the production of smaller and more complex semiconductor devices. As of 2025, the market for advanced etching equipment is expected to grow significantly, driven by the need for higher yields and lower defect rates in semiconductor manufacturing. This trend suggests that companies investing in cutting-edge dielectric etching technologies will likely gain a competitive edge. Furthermore, the integration of artificial intelligence and machine learning into etching processes is anticipated to optimize operational efficiency, thereby further stimulating growth in the Dielectric Etcher Market.