Elastic Adhesive Size

Elastic Adhesive Market Growth Projections and Opportunities

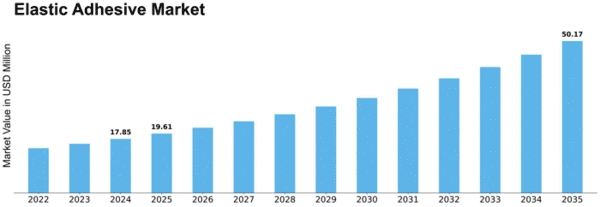

The Elastic Adhesive Market is influenced by a myriad of factors that collectively shape its dynamics and growth trajectory. One of the primary market factors is the increasing demand from diverse industries such as construction, automotive, and healthcare. As these sectors continue to expand, the need for elastic adhesives rises due to their versatile applications in bonding various materials. Additionally, the construction industry's emphasis on sustainable and energy-efficient structures has led to a surge in the adoption of elastic adhesives, which offer flexibility, durability, and eco-friendly attributes. Elastic Adhesive Market is projected to be worth USD 31.82 Million by 2030, registering a CAGR of 6.3% during the forecast period (2022 - 2028).

Technological advancements play a crucial role in shaping the Elastic Adhesive Market landscape. Continuous research and development efforts contribute to the formulation of innovative adhesive solutions with enhanced performance characteristics. Manufacturers are investing in developing adhesives that not only provide superior bonding capabilities but also address specific industry challenges. The evolution of these advanced formulations strengthens the market's competitiveness and opens up new opportunities for growth.

Global economic conditions and regional market trends are pivotal market factors influencing the elastic adhesive industry. Economic stability, consumer purchasing power, and overall market sentiment impact the demand for elastic adhesives. In regions experiencing rapid industrialization and infrastructure development, the demand for these adhesives is often on the rise. Conversely, economic downturns may lead to fluctuations in demand, affecting market growth. Understanding and adapting to regional market trends are crucial for stakeholders to navigate the elastic adhesive landscape effectively.

Regulatory frameworks and environmental considerations significantly shape the Elastic Adhesive Market. Stringent regulations governing the use of certain chemicals and the push towards eco-friendly products influence the formulation and production of elastic adhesives. Manufacturers are increasingly focusing on developing adhesives that comply with environmental standards and regulations. This not only ensures market compliance but also aligns with the growing consumer preference for sustainable and eco-conscious products.

The competitive landscape and industry consolidation also play a pivotal role in determining market dynamics. The presence of established players, new entrants, and strategic partnerships influence the market's overall competitiveness. Mergers and acquisitions, as well as collaborations between key players, can lead to the expansion of product portfolios and market reach. Moreover, competition often drives innovation as companies strive to differentiate their offerings and gain a competitive edge in the market.

Raw material availability and pricing are fundamental factors that impact the Elastic Adhesive Market. Fluctuations in the prices of key raw materials, such as polymers and resins, directly affect production costs and, consequently, product pricing. Manufacturers need to navigate these challenges by establishing resilient supply chains, exploring alternative raw materials, and adopting cost-effective production processes to maintain competitiveness in the market.

Consumer preferences and evolving end-user industries also contribute to the market dynamics of elastic adhesives. The demand for specific product attributes, such as faster curing times, improved flexibility, and compatibility with different substrates, drives innovation within the industry. Understanding and responding to these changing preferences are critical for manufacturers to stay relevant and meet the evolving needs of end-users.

Leave a Comment