Government Incentives and Support

Government initiatives aimed at promoting electric vehicle adoption are significantly influencing the Electric Vehicle Battery Manufacturing Equipment Market. Various countries are offering incentives such as tax rebates, grants, and subsidies to both consumers and manufacturers. These measures encourage investment in EV infrastructure and battery production capabilities. For instance, recent policies in several regions have allocated substantial funding for the development of battery manufacturing facilities. This financial support not only boosts the production capacity of battery manufacturers but also stimulates the demand for advanced manufacturing equipment. As a result, the Electric Vehicle Battery Manufacturing Equipment Market is likely to experience accelerated growth due to favorable government policies.

Rising Demand for Electric Vehicles

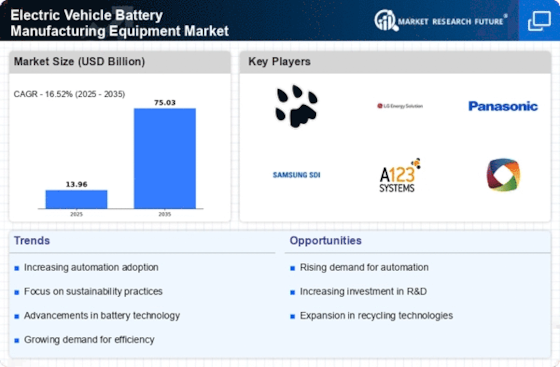

The increasing consumer preference for electric vehicles (EVs) is a primary driver for the Electric Vehicle Battery Manufacturing Equipment Market. As governments and organizations worldwide implement stringent regulations to reduce carbon emissions, the demand for EVs is projected to rise significantly. According to recent data, the EV market is expected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This surge in demand necessitates advanced battery manufacturing equipment to ensure efficient production processes. Consequently, manufacturers are investing heavily in innovative technologies to enhance battery performance and reduce costs. The Electric Vehicle Battery Manufacturing Equipment Market is thus poised for substantial growth as it adapts to meet the evolving needs of the automotive sector.

Focus on Sustainable Manufacturing Practices

The growing emphasis on sustainability within the manufacturing sector is a crucial driver for the Electric Vehicle Battery Manufacturing Equipment Market. Manufacturers are increasingly adopting eco-friendly practices to minimize their environmental impact. This shift includes the use of renewable energy sources in production processes and the implementation of recycling programs for battery materials. As sustainability becomes a priority, the demand for specialized manufacturing equipment that aligns with these practices is expected to rise. Companies that invest in sustainable battery manufacturing technologies are likely to gain a competitive edge, further propelling the growth of the Electric Vehicle Battery Manufacturing Equipment Market.

Technological Advancements in Battery Technology

Technological innovations in battery technology are driving the Electric Vehicle Battery Manufacturing Equipment Market forward. The development of high-capacity batteries, such as solid-state and lithium-sulfur batteries, is revolutionizing the EV landscape. These advancements not only improve energy density but also enhance safety and longevity, making electric vehicles more appealing to consumers. As manufacturers strive to keep pace with these innovations, they require sophisticated manufacturing equipment capable of producing next-generation batteries. The market for battery manufacturing equipment is expected to expand as companies seek to integrate cutting-edge technologies into their production lines, thereby increasing efficiency and reducing production costs.

Increasing Investment in Research and Development

Investment in research and development (R&D) is a vital driver for the Electric Vehicle Battery Manufacturing Equipment Market. As competition intensifies, manufacturers are allocating significant resources to R&D to innovate and improve battery technologies. This focus on R&D aims to enhance battery performance, reduce costs, and develop new manufacturing techniques. Recent statistics indicate that R&D spending in the battery sector has increased substantially, reflecting the industry's commitment to advancing battery technology. This trend not only fosters innovation but also creates a demand for advanced manufacturing equipment capable of supporting new production methods. Consequently, the Electric Vehicle Battery Manufacturing Equipment Market is likely to benefit from these ongoing investments.