Technological Advancements in ESD Films

Innovations in material science are playing a pivotal role in shaping the Electrostatic Discharge Film Market. The development of advanced ESD films, which offer enhanced performance characteristics such as improved durability and flexibility, is attracting attention from manufacturers. These technological advancements enable the production of thinner films without compromising on protective capabilities, thus catering to the evolving needs of the electronics sector. Furthermore, the introduction of eco-friendly materials in ESD film production aligns with the growing emphasis on sustainability. As a result, the Electrostatic Discharge Film Market is poised for expansion, with new product offerings that meet both performance and environmental standards.

Increasing Adoption of ESD Protection Solutions

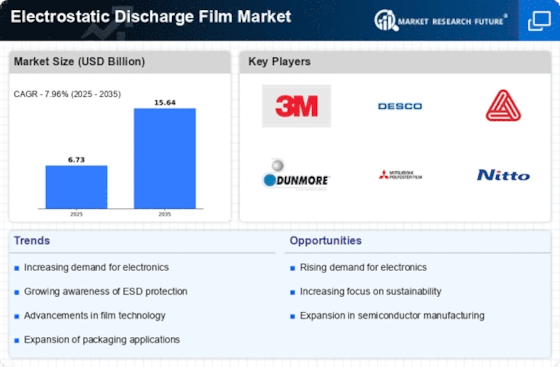

The rising awareness regarding the importance of electrostatic discharge (ESD) protection in various industries is driving the Electrostatic Discharge Film Market. As electronic devices become more sophisticated, the risk of ESD damage increases, prompting manufacturers to adopt protective measures. This trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where the integration of sensitive components necessitates robust ESD solutions. According to industry reports, the demand for ESD protective materials is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years. Consequently, the Electrostatic Discharge Film Market is likely to experience significant growth as companies prioritize the safeguarding of their products against ESD-related failures.

Regulatory Standards and Compliance Requirements

The implementation of stringent regulatory standards and compliance requirements is influencing the Electrostatic Discharge Film Market. Various industries, particularly electronics and automotive, are mandated to adhere to specific ESD protection guidelines to ensure product reliability and safety. These regulations compel manufacturers to invest in ESD protective solutions, including films, to mitigate the risks associated with electrostatic discharge. As compliance becomes a critical factor in product development, the demand for high-quality ESD films is likely to increase. This trend not only drives the Electrostatic Discharge Film Market but also encourages innovation in product offerings to meet regulatory expectations.

Expansion of the Electronics Manufacturing Sector

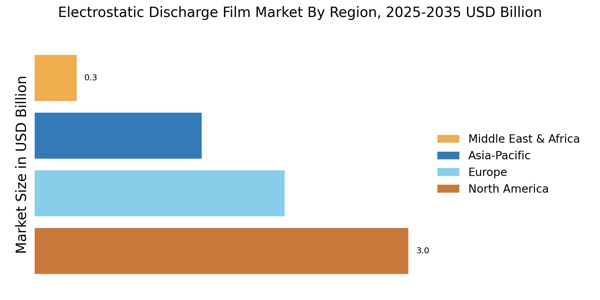

The continuous expansion of the electronics manufacturing sector is a key driver for the Electrostatic Discharge Film Market. As countries invest in building robust manufacturing infrastructures, the demand for ESD protection solutions is expected to rise. For instance, regions with burgeoning electronics hubs are witnessing an increase in the production of consumer electronics, semiconductors, and other electronic components. This surge in manufacturing activities necessitates the use of ESD films to prevent damage during production and transportation. Market analysts estimate that the electronics manufacturing sector will contribute significantly to the growth of the Electrostatic Discharge Film Market, with a projected increase in demand for ESD films by over 8% in the coming years.

Growing Awareness of ESD Risks in Various Industries

The growing awareness of the risks associated with electrostatic discharge across multiple industries is propelling the Electrostatic Discharge Film Market. As organizations recognize the potential financial losses and operational disruptions caused by ESD-related failures, there is a concerted effort to implement protective measures. This awareness is particularly pronounced in sectors such as aerospace, healthcare, and telecommunications, where the integrity of electronic components is paramount. Educational initiatives and training programs aimed at highlighting ESD risks are further contributing to this trend. Consequently, the Electrostatic Discharge Film Market is likely to benefit from increased investments in ESD protection solutions as companies strive to safeguard their assets.

.png)