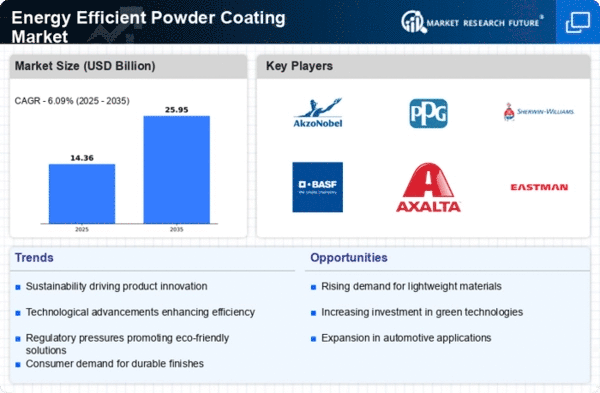

The Energy Efficient Powder Coating Market is currently characterized by a dynamic competitive landscape, driven by increasing demand for sustainable and environmentally friendly coating solutions. Key players such as AkzoNobel (NL), PPG Industries (US), and Sherwin-Williams (US) are actively positioning themselves through innovation and strategic partnerships. AkzoNobel (NL) emphasizes its commitment to sustainability, focusing on developing eco-friendly products that meet stringent environmental regulations. PPG Industries (US) has been enhancing its product portfolio with advanced technologies aimed at improving energy efficiency, while Sherwin-Williams (US) is leveraging its extensive distribution network to expand its market reach. Collectively, these strategies contribute to a competitive environment that prioritizes sustainability and technological advancement.In terms of business tactics, companies are increasingly localizing manufacturing to reduce transportation emissions and optimize supply chains. The market structure appears moderately fragmented, with several players competing for market share. This fragmentation allows for niche players to emerge, while larger companies leverage their resources to maintain a competitive edge. The collective influence of these key players shapes market dynamics, as they strive to meet the growing demand for energy-efficient solutions.

In November AkzoNobel (NL) announced the launch of a new line of powder coatings designed specifically for the automotive sector, which are claimed to reduce energy consumption during application by up to 30%. This strategic move not only reinforces AkzoNobel's commitment to sustainability but also positions the company to capture a larger share of the automotive market, which is increasingly focused on reducing its carbon footprint. The introduction of these innovative products is likely to enhance customer loyalty and attract new clients seeking environmentally responsible options.

In October PPG Industries (US) unveiled a partnership with a leading technology firm to develop AI-driven solutions for optimizing powder coating processes. This collaboration aims to enhance operational efficiency and reduce waste, aligning with the industry's shift towards digital transformation. By integrating AI into its manufacturing processes, PPG Industries (US) is poised to improve product quality and reduce costs, thereby strengthening its competitive position in the market.

In September Sherwin-Williams (US) expanded its production capabilities by investing in a new facility dedicated to energy-efficient powder coatings in the Midwest. This strategic investment is expected to increase production capacity by 25%, allowing the company to meet rising demand while minimizing its environmental impact. The establishment of this facility not only enhances Sherwin-Williams' operational efficiency but also underscores its commitment to sustainability and innovation in the powder coating sector.

As of December current competitive trends indicate a strong focus on digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are increasingly shaping the landscape, enabling companies to leverage complementary strengths and enhance their market offerings. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability. This shift suggests that companies that prioritize sustainable practices and invest in cutting-edge technologies will be better positioned to thrive in the Energy Efficient Powder Coating Market.