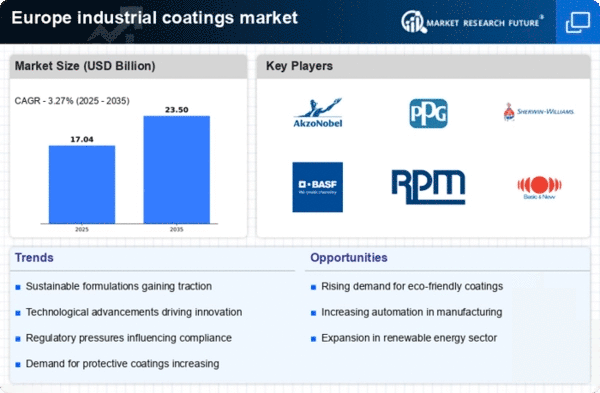

Regulatory Compliance Pressure

is increasingly shaped by stringent regulatory frameworks that aim to reduce environmental impact.. Regulations such as REACH and VOC limits compel manufacturers to innovate and adapt their products to meet compliance standards. This pressure not only drives the demand for eco-friendly coatings but also encourages investment in research and development. As a result, companies are likely to focus on formulating coatings that are less harmful to the environment while maintaining performance. The need for compliance is expected to grow, potentially leading to a market shift towards sustainable solutions, which could account for a significant share of the industrial coatings market in Europe.

Growth in Renewable Energy Sector

The renewable energy sector is emerging as a significant driver for the industrial coatings market in Europe. As the demand for renewable energy sources, such as wind and solar, continues to rise, the need for specialized coatings that can withstand extreme conditions is becoming increasingly important. Coatings used in wind turbines and solar panels must offer exceptional durability and resistance to environmental factors. In 2025, it is anticipated that the renewable energy sector will contribute to approximately 15% of the industrial coatings market. This growth reflects a broader trend towards sustainability and the need for coatings that support the longevity and efficiency of renewable energy technologies.

Rising Demand from Automotive Sector

The automotive industry remains a pivotal driver for the industrial coatings market in Europe. With the increasing production of vehicles, the demand for high-performance coatings that provide durability and aesthetic appeal is on the rise. In 2025, the automotive sector is projected to contribute approximately 30% to the overall industrial coatings market. This growth is fueled by the need for coatings that can withstand harsh environmental conditions while offering enhanced protection against corrosion and wear. As manufacturers strive to meet consumer expectations for quality and sustainability, the industrial coatings market is likely to see innovations tailored specifically for automotive applications.

Infrastructure Development Initiatives

Infrastructure development initiatives across Europe are significantly impacting the industrial coatings market. Governments are investing heavily in public infrastructure projects, including roads, bridges, and buildings, which require protective coatings to enhance longevity and performance. In 2025, it is estimated that infrastructure projects will account for around 25% of the total demand for industrial coatings. This trend is driven by the need for durable and weather-resistant coatings that can withstand the rigors of outdoor exposure. As urbanization continues to rise, is likely to benefit from increased demand for protective solutions in construction and infrastructure..

Technological Innovations in Coating Applications

Technological innovations are reshaping the industrial coatings market in Europe, leading to the development of advanced application techniques. Innovations such as electrostatic spray, powder coating, and nanotechnology are enhancing the efficiency and effectiveness of coatings. These technologies not only improve the application process but also contribute to better performance characteristics, such as adhesion and resistance to chemicals. As manufacturers adopt these advanced techniques, the market is likely to witness a shift towards more efficient and sustainable coating solutions. The integration of technology in coating applications is expected to drive growth in the industrial coatings market, potentially increasing market share for innovative products.