Market Trends

Key Emerging Trends in the Fiber-Reinforced Plastic Grating Market

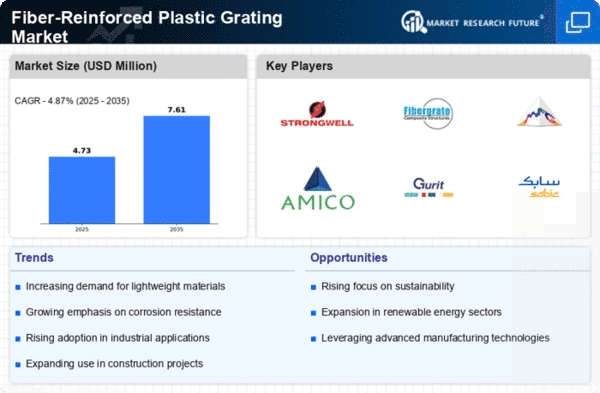

The Fiber-Reinforced Plastic (FRP) grating market is undergoing significant trends that reflect the growing adoption of these versatile materials in various industries. FRP grating, made from reinforced plastic materials such as fiberglass, is known for its lightweight, corrosion resistance, and high strength-to-weight ratio. One notable trend is the increasing use of FRP grating in the construction and infrastructure sectors. The construction industry is incorporating FRP grating in applications such as walkways, platforms, and bridges due to its durability, low maintenance requirements, and resistance to environmental elements. This trend is driven by the desire for longer-lasting and cost-effective solutions in construction projects.

Moreover, the market is witnessing a surge in demand for FRP grating in industries requiring anti-corrosive and non-conductive solutions. The chemical and petrochemical industries, in particular, favor FRP grating for its resistance to corrosive chemicals and its non-conductive properties. As safety standards become more stringent, industries are adopting FRP grating in areas where traditional materials may deteriorate due to exposure to harsh chemicals, ensuring a safer working environment.

Additionally, there is a growing focus on sustainability and eco-friendly materials in the FRP grating market. Manufacturers are increasingly using recycled materials in the production of FRP grating, aligning with the global push towards more sustainable and environmentally conscious practices. This trend resonates with customers who prioritize green solutions, and it reflects the industry's commitment to reducing its environmental footprint.

Furthermore, the market is influenced by the versatility of FRP grating in marine and offshore applications. The corrosion-resistant nature of FRP makes it an ideal material for use in marine environments, including offshore platforms, ship decks, and marinas. The durability and low maintenance requirements of FRP grating contribute to its popularity in these applications, where exposure to saltwater and harsh weather conditions can pose challenges for traditional materials.

The transportation and automotive industries are also contributing to the growth of the FRP grating market. FRP composites are used in the manufacturing of vehicle components, including grilles, floor panels, and interior components. The lightweight nature of FRP grating supports fuel efficiency and reduces the overall weight of vehicles, making it an attractive option for manufacturers seeking to meet stringent emission standards.

Despite these positive trends, challenges exist within the FRP grating market. The initial cost of FRP materials may be higher compared to traditional materials, posing a consideration for budget-conscious projects. However, the long-term benefits of reduced maintenance costs, extended lifespan, and the versatility of FRP grating often outweigh the initial investment, leading to its increased adoption in various applications.

Leave a Comment