Research Methodology on Glass Fiber Reinforced Plastic Market

Introduction

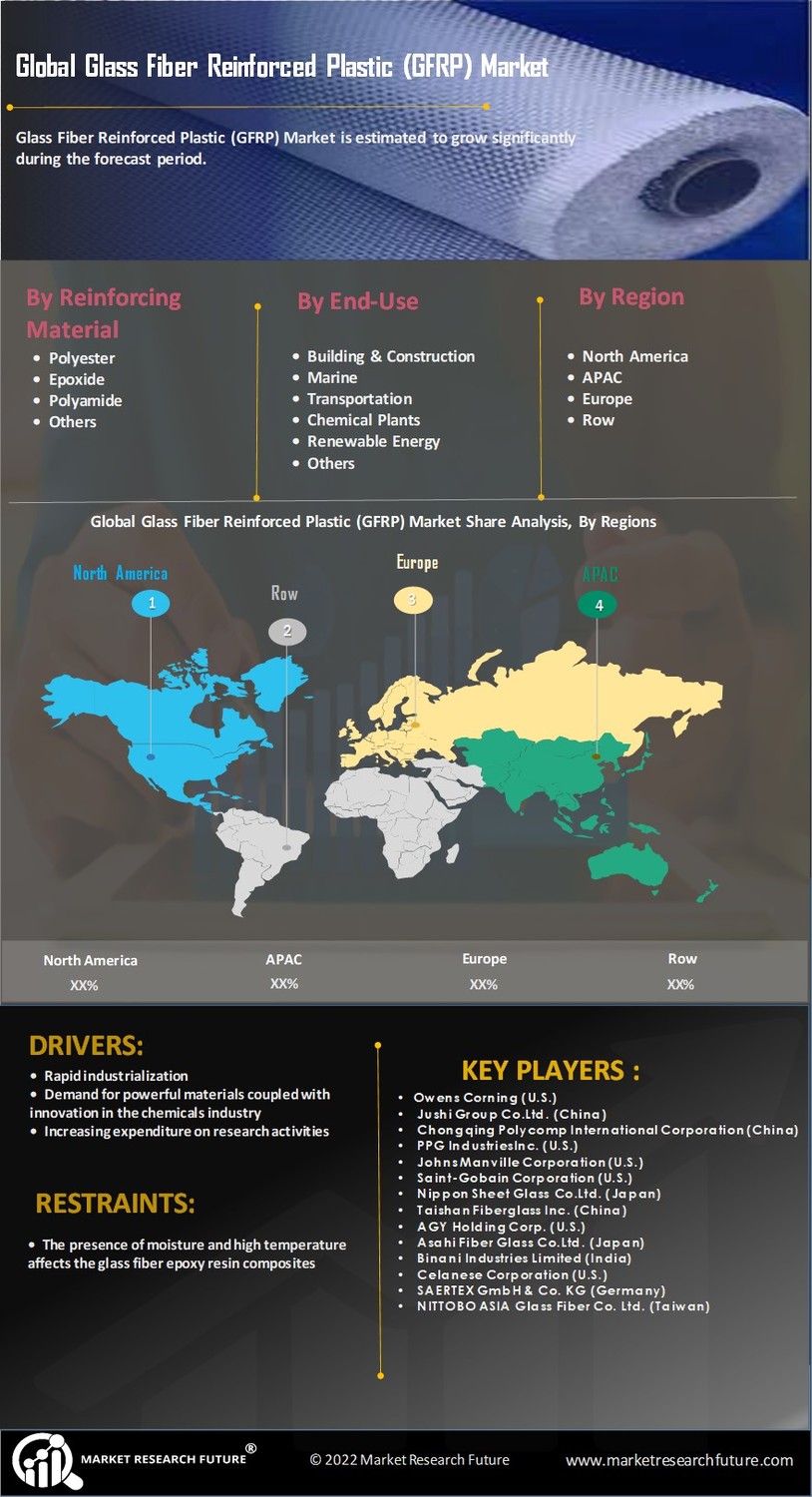

Glass Fiber Reinforced Plastic (GFRP) is a strong and light polymer with high strength, stiffness, and thermal and chemical resistance, making it an important material for a variety of applications ranging from chemical processing equipment to structural components, and even marine construction materials. The Global Glass Fiber Reinforced Plastic (GFRP) Market is expected to grow significantly during the forecast period 2023 to 2030. The increase in demand for GFRP from various industries such as transportation, marine, and civil engineering is driving the growth of the market.

Research Methodology

A thorough research methodology is essential for any market research project. This research report aims to provide a detailed analysis of the Global Glass Fiber Reinforced Plastic (GFRP) Market. This report follows a rigorous and in-depth research methodology that involves secondary research, primary research, and other methods of analyzing the data. The research methodology used in this report will help provide a better understanding of the various drivers, trends, and challenges of the Global GFRP Market.

Secondary Research

Secondary research is one of the primary methods used to derive information about the Global GFRP market. Various industry-leading sources such as market reports, white papers, and industry databases were consulted to gain insights into the market. Standard sources such as newspaper articles, magazine articles, and online websites, along with reliable sources such as Bloomberg, Frost and Sullivan, McKinsey & Company, Deloitte, PwC, and more were consulted for secondary research. As part of our secondary research, we also examined the past trends in the GFRP market and analysed the factors that are expected to shape the future of the market.

Primary Research

Primary research is also an important part of our research methodology. Primary research involved interviews with key industry stakeholders such as manufacturers, suppliers, and distributors, as well as industry experts and end-users. We conducted in-depth interviews to get their insight into the various aspects of the market. Various research tools and techniques such as structured interviews and focus group discussions were used to collect primary data.

Approaches Used

We employed a modified bottom-up approach to estimate the market size of the Global GFRP Market. We also used top-down and factor analysis to validate the estimated market size. Our market estimates were further triangulated using demand-side and supply-side data. The demand-side data included the views of key industry stakeholders. The supply-side data included the historical data and market trends of various segments. We also used time-series analysis to forecast the growth of the Global GFRP Market during the forecast period 2023 to 2030.

Conclusion

The research methodology used in this report provides an in-depth and comprehensive understanding of the Global Glass Fiber Reinforced Plastic (GFRP) Market. Secondary research, primary research, and various other approaches such as bottom-up, top-down, factor analysis, time-series analysis, and demand-side and supply-side data triangulation were used to derive accurate information about the market. This enables a thorough understanding of the market drivers, trends, and challenges, which will help our readers make informed decisions.