Regulatory Compliance

Regulatory compliance is becoming increasingly important within the Flexible Letterpress Printing Ink Market. As governments and regulatory bodies implement stricter guidelines regarding the use of chemicals in inks, manufacturers are compelled to adapt their formulations to meet these standards. This trend is particularly relevant in regions where environmental regulations are stringent, leading to a shift towards safer and more compliant ink products. Companies that proactively address these regulatory challenges are likely to enhance their market position and appeal to environmentally conscious consumers. The market is witnessing a gradual transition towards inks that are free from harmful substances, which could potentially reshape product offerings and influence purchasing decisions in the coming years.

Sustainability Initiatives

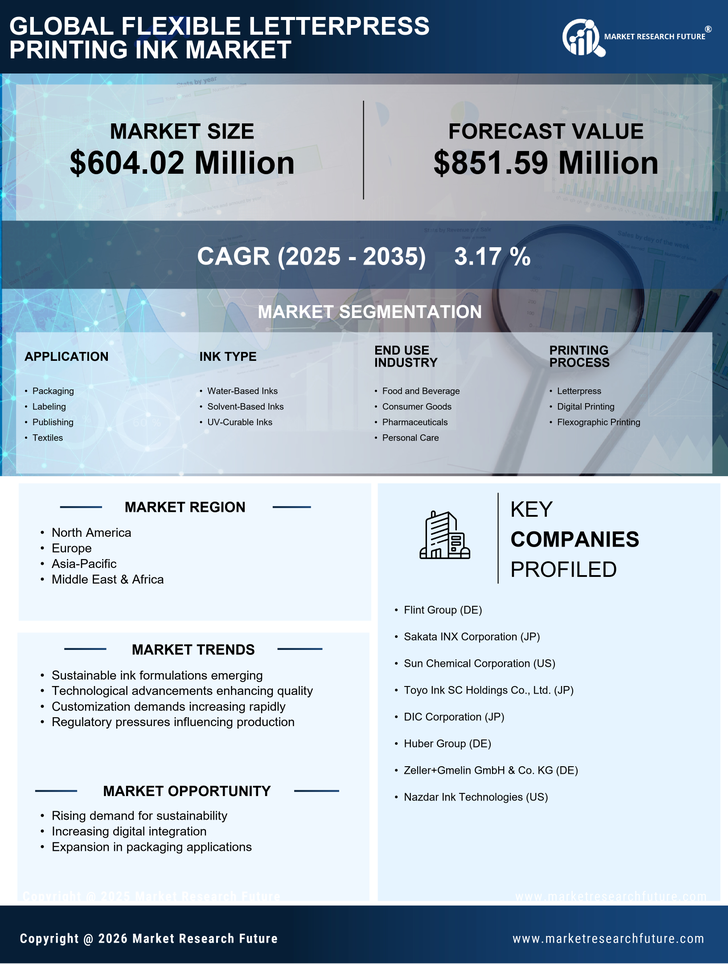

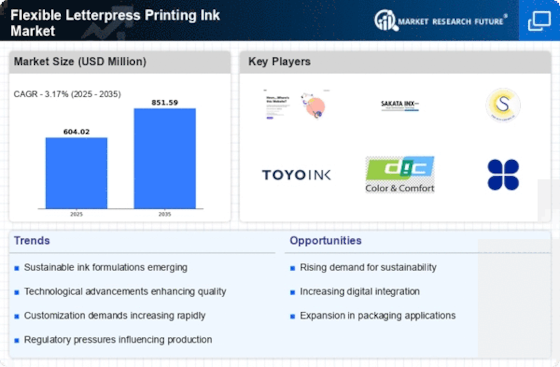

The increasing emphasis on sustainability within the Flexible Letterpress Printing Ink Market is driving demand for eco-friendly inks. Manufacturers are focusing on developing inks that are biodegradable and made from renewable resources. This shift aligns with consumer preferences for environmentally responsible products, which has been observed to influence purchasing decisions significantly. As a result, companies that prioritize sustainable practices are likely to gain a competitive edge. The market for sustainable inks is projected to grow, with estimates suggesting a compound annual growth rate of over 5% in the coming years. This trend not only reflects a broader societal shift towards sustainability but also indicates a potential for innovation in ink formulations that meet these new standards.

Technological Advancements

Technological advancements are playing a crucial role in shaping the Flexible Letterpress Printing Ink Market. Innovations in ink formulation and printing technology are enhancing the performance and versatility of letterpress inks. For instance, the introduction of digital printing techniques has allowed for greater precision and efficiency in the printing process. This has led to an increase in the adoption of letterpress printing for various applications, including packaging and labels. Furthermore, advancements in color matching and consistency are enabling printers to achieve higher quality results. The market is witnessing a shift towards inks that can be used across multiple substrates, which is likely to expand the potential customer base and applications for letterpress printing.

Growth in Packaging Industry

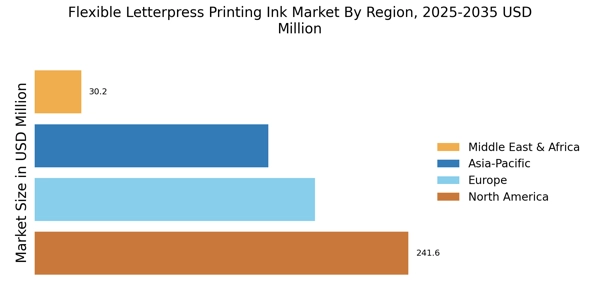

The growth of the packaging industry is significantly influencing the Flexible Letterpress Printing Ink Market. As consumer preferences shift towards more sustainable and visually appealing packaging, the demand for high-quality printing inks is increasing. The packaging sector is projected to expand at a compound annual growth rate of approximately 4% in the coming years, which is expected to drive the demand for letterpress inks. This growth is particularly notable in sectors such as food and beverage, where packaging plays a critical role in attracting consumers. Manufacturers are responding to this trend by developing inks that not only meet regulatory standards but also enhance the aesthetic appeal of packaging. This alignment with market needs suggests a robust future for letterpress printing inks in the packaging domain.

Customization and Personalization

The demand for customization and personalization in the Flexible Letterpress Printing Ink Market is on the rise. Businesses are increasingly seeking unique and tailored printing solutions to differentiate their products in a competitive marketplace. This trend is particularly evident in sectors such as packaging, where brands are looking to create distinctive designs that resonate with consumers. The ability to offer customized inks that cater to specific client needs is becoming a key selling point for manufacturers. Market data indicates that the customization segment is expected to grow significantly, with projections suggesting a potential increase in market share of around 10% over the next few years. This shift towards personalized products is likely to drive innovation in ink formulations and printing techniques.