Sustainability Initiatives

Sustainability initiatives are becoming increasingly pivotal within the Flexible Metallic Tubing Market. As environmental concerns rise, manufacturers are adopting eco-friendly practices, such as using recyclable materials and reducing waste during production. This shift not only aligns with regulatory requirements but also caters to the growing consumer preference for sustainable products. Companies that prioritize sustainability are likely to gain a competitive edge, as they appeal to environmentally conscious clients. Furthermore, the integration of sustainable practices can lead to cost savings in the long run, enhancing profitability. The market is witnessing a gradual transition towards greener alternatives, which is expected to influence purchasing decisions significantly.

Increased Demand in Emerging Markets

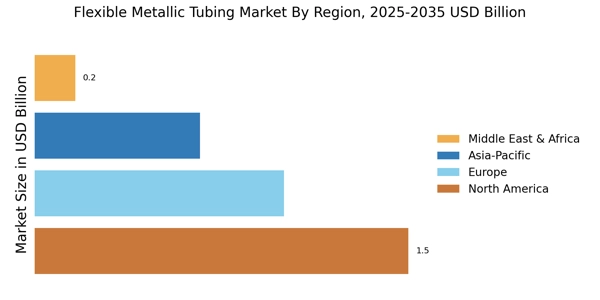

The Flexible Metallic Tubing Market is witnessing a surge in demand from emerging markets, particularly in regions such as Asia-Pacific and Latin America. Rapid industrialization and urbanization in these areas are driving the need for flexible metallic tubing in various applications, including construction, automotive, and energy sectors. For example, the Asia-Pacific region is projected to account for a substantial share of the market, with an expected growth rate of over 6% annually. This demand is fueled by infrastructure development and the expansion of manufacturing capabilities. As these markets continue to evolve, they present lucrative opportunities for manufacturers to expand their reach and enhance their product offerings.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards play a crucial role in shaping the Flexible Metallic Tubing Market. Stringent regulations regarding product quality and safety are compelling manufacturers to adhere to higher standards in their production processes. Compliance with international standards, such as ISO and ASTM, is essential for gaining market access and ensuring customer trust. This focus on safety not only protects end-users but also enhances the reputation of manufacturers. As industries such as oil and gas, pharmaceuticals, and food processing increasingly prioritize safety, the demand for compliant flexible metallic tubing is likely to rise. This trend underscores the importance of maintaining high-quality production practices.

Technological Advancements in Manufacturing

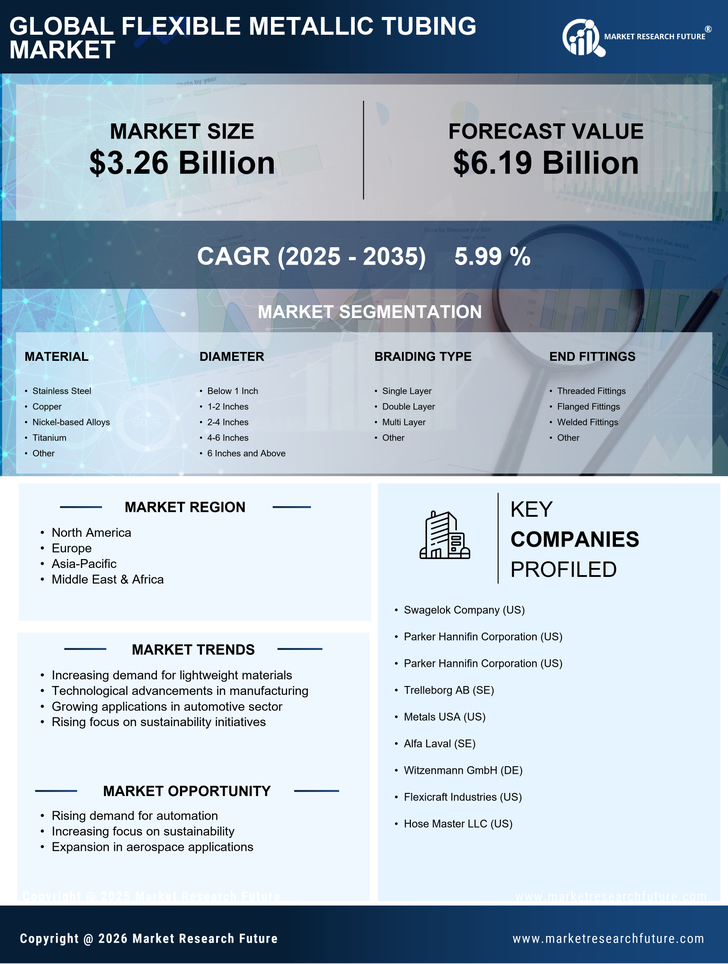

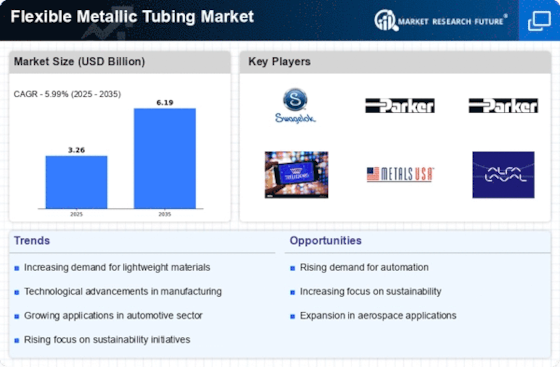

The Flexible Metallic Tubing Market is experiencing a notable transformation due to advancements in manufacturing technologies. Innovations such as automated production lines and enhanced material processing techniques are streamlining the production of flexible metallic tubing. These advancements not only improve efficiency but also enhance the quality and durability of the products. For instance, the introduction of computer numerical control (CNC) machining allows for precise fabrication, which is crucial in industries such as aerospace and automotive. As a result, manufacturers are better equipped to meet the increasing demand for high-performance tubing solutions. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years, driven by these technological improvements.

Growing Applications Across Diverse Industries

The Flexible Metallic Tubing Market is expanding due to its growing applications across diverse industries. From aerospace to medical devices, the versatility of flexible metallic tubing is being recognized for its ability to withstand extreme conditions and provide reliable performance. In the aerospace sector, for instance, the lightweight and durable nature of these tubes is essential for fuel efficiency and safety. Similarly, in the medical field, flexible metallic tubing is utilized in various devices, enhancing patient care. The increasing adoption of these tubes in innovative applications is expected to drive market growth, with projections indicating a potential increase in demand by 7% over the next few years.