Customization Demand

The demand for customization is reshaping the Flexographic Ink Market. As brands seek to differentiate themselves, personalized packaging solutions have gained traction. This trend is particularly pronounced in sectors such as food and beverage, where unique designs can enhance consumer engagement. In 2025, the market for customized inks is projected to grow by approximately 6%, driven by the need for short-run printing and quick turnaround times. Manufacturers are responding by offering a wider range of colors and finishes, allowing businesses to create distinctive packaging that resonates with their target audience. This shift towards customization is likely to drive innovation and competition within the Flexographic Ink Market.

Regulatory Compliance

Regulatory compliance is a critical driver in the Flexographic Ink Market. Governments worldwide are implementing stringent regulations regarding the use of hazardous materials in inks. This has prompted manufacturers to reformulate their products to meet safety standards, particularly in food packaging applications. In 2025, it is estimated that compliance-related costs could account for up to 15% of total production expenses for ink manufacturers. As a result, companies are investing in safer, compliant ink formulations that do not compromise on performance. This focus on regulatory adherence not only ensures consumer safety but also enhances the reputation of the Flexographic Ink Market as a responsible sector.

Technological Innovations

Technological innovations play a pivotal role in the evolution of the Flexographic Ink Market. Advancements in ink formulation and printing technology have led to improved print quality and efficiency. For instance, the introduction of digital flexo printing has enhanced color accuracy and reduced waste, making it a preferred choice for many manufacturers. The market is expected to witness a surge in the adoption of high-performance inks that offer better adhesion and faster drying times. By 2025, the segment of high-performance inks is anticipated to account for over 30% of the total market share. This technological progression not only enhances productivity but also positions the Flexographic Ink Market as a leader in innovative printing solutions.

Sustainability Initiatives

The Flexographic Ink Market is increasingly influenced by sustainability initiatives. As environmental concerns rise, manufacturers are compelled to adopt eco-friendly practices. This shift is evident in the growing demand for water-based inks, which are perceived as less harmful compared to solvent-based alternatives. In 2025, the market for sustainable inks is projected to reach approximately 1.5 billion USD, reflecting a compound annual growth rate of around 5%. Companies are investing in research and development to create inks that not only meet regulatory standards but also appeal to environmentally conscious consumers. This trend is likely to reshape product offerings and marketing strategies within the Flexographic Ink Market, as businesses strive to align with consumer preferences for sustainable products.

Market Expansion in Emerging Economies

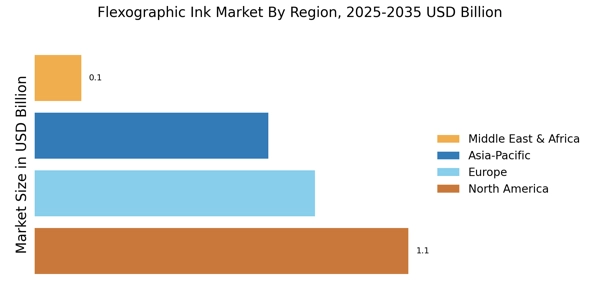

Market expansion in emerging economies is significantly impacting the Flexographic Ink Market. As industrialization accelerates in regions such as Asia-Pacific and Latin America, the demand for flexible packaging solutions is on the rise. This trend is expected to drive the growth of the flexographic ink segment, with a projected increase of 7% in these markets by 2025. The burgeoning e-commerce sector further fuels this demand, as brands seek efficient packaging solutions to meet consumer expectations. Companies are likely to establish local production facilities to cater to these markets, thereby enhancing their competitive edge. This expansion presents both opportunities and challenges for the Flexographic Ink Market, necessitating strategic adaptations to local market dynamics.