Customization Demand

The rising demand for customization in packaging and printing is significantly influencing the Flexographic Printing Ink Market. Brands are increasingly seeking unique packaging solutions that stand out on shelves, leading to a surge in demand for customized inks. This trend is particularly evident in sectors such as food and beverage, where packaging plays a crucial role in consumer choice. Market analysis suggests that the customization segment could account for nearly 30% of the total flexographic ink market by 2026. As companies strive to differentiate their products, the need for specialized inks that cater to specific design requirements is likely to grow, further propelling market expansion.

Regulatory Compliance

Regulatory compliance is becoming an essential driver in the Flexographic Printing Ink Market. Governments worldwide are implementing stricter regulations regarding the use of hazardous materials in inks, pushing manufacturers to reformulate their products. Compliance with these regulations not only ensures safety but also opens up new market opportunities for compliant products. The market is witnessing a shift towards inks that meet these stringent standards, which is expected to increase the market share of compliant flexographic inks by approximately 15% over the next few years. Companies that proactively adapt to these regulations are likely to enhance their market position and appeal to a broader customer base.

Sustainability Initiatives

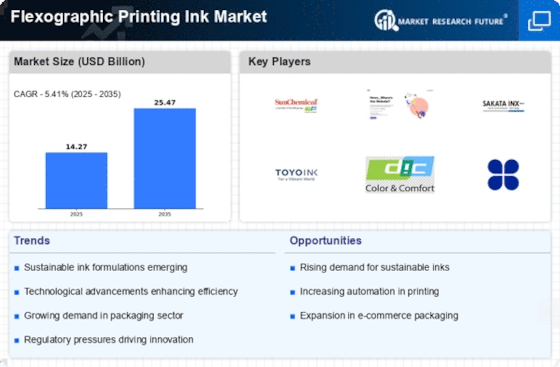

The increasing emphasis on sustainability within the Flexographic Printing Ink Market is driving demand for eco-friendly inks. Manufacturers are increasingly adopting bio-based and water-based inks, which are less harmful to the environment compared to traditional solvent-based inks. This shift is not merely a trend but a response to regulatory pressures and consumer preferences for sustainable products. As a result, the market for sustainable flexographic inks is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. Companies that prioritize sustainability are likely to gain a competitive edge, appealing to environmentally conscious consumers and businesses alike.

Technological Advancements

Technological integration is a pivotal driver in the Flexographic Printing Ink Market. Innovations in ink formulation and printing technology are enhancing the performance and efficiency of flexographic inks. For instance, advancements in digital printing technologies are allowing for quicker changeovers and reduced waste, which is particularly beneficial for short-run printing jobs. Moreover, the development of high-performance inks that offer better adhesion and drying times is expanding the application scope of flexographic printing. Market data indicates that the adoption of advanced technologies could lead to a 10% increase in production efficiency, thereby attracting more businesses to the flexographic printing process.

Growth in Packaging Industry

The robust growth of the packaging industry is a primary driver for the Flexographic Printing Ink Market. As consumer demand for packaged goods continues to rise, the need for high-quality printing inks is also increasing. Flexographic printing is favored for its efficiency and versatility, making it a preferred choice for packaging applications. Market data indicates that the packaging sector is projected to grow at a rate of 4% annually, which directly correlates with the demand for flexographic inks. This growth is particularly pronounced in sectors such as e-commerce and food packaging, where visually appealing and durable packaging is essential for brand success.