Rising Focus on Food Safety and Quality

The Food Spray Drying Equipment Market is significantly influenced by the rising focus on food safety and quality standards. Regulatory bodies are increasingly enforcing stringent guidelines to ensure that food products are safe for consumption. Spray drying technology is advantageous in this regard, as it effectively reduces microbial load and extends the shelf life of food products. This capability is particularly important for manufacturers looking to comply with food safety regulations while maintaining product quality. The Food Spray Drying Equipment Market is expected to reach USD 20 billion by 2025, indicating a growing emphasis on safety measures in food production. Consequently, the demand for reliable food spray drying equipment is likely to increase as manufacturers seek to enhance their safety protocols.

Expansion of the Food Processing Industry

The Food Spray Drying Equipment Market is closely linked to the expansion of the food processing sector. As urbanization and population growth continue to rise, there is an increasing need for processed food products that are convenient and have a longer shelf life. Spray drying technology plays a crucial role in this context, as it allows for the efficient conversion of liquid food products into dry powders, which are easier to store and transport. The food processing industry is projected to grow at a rate of 5% annually, further driving the demand for food spray drying equipment. This expansion presents a significant opportunity for manufacturers to innovate and enhance their product offerings to meet the needs of a rapidly evolving market.

Sustainability and Environmental Considerations

The Food Spray Drying Equipment Market is increasingly shaped by sustainability and environmental considerations. As consumers and businesses alike become more aware of their environmental impact, there is a growing demand for equipment that minimizes energy consumption and waste. Spray drying technology can be optimized to reduce water usage and energy costs, making it a more sustainable option for food processing. Furthermore, manufacturers are exploring the use of renewable energy sources to power their equipment, aligning with global sustainability goals. The market for sustainable food processing solutions is projected to grow significantly, suggesting that food spray drying equipment manufacturers who prioritize sustainability will likely gain a competitive edge in the industry.

Increasing Demand for Natural and Organic Products

The Food Spray Drying Equipment Market is witnessing a notable increase in demand for natural and organic food products. Consumers are becoming more health-conscious and are seeking products that are free from artificial additives and preservatives. Spray drying technology is particularly advantageous for preserving the natural qualities of fruits, vegetables, and herbs, making it an ideal choice for manufacturers aiming to produce organic offerings. The market for organic food is expected to reach USD 300 billion by 2025, which suggests a significant opportunity for food spray drying equipment manufacturers to cater to this growing segment. This trend highlights the importance of adapting equipment to meet the specific requirements of organic food production.

Technological Innovations in Food Spray Drying Equipment

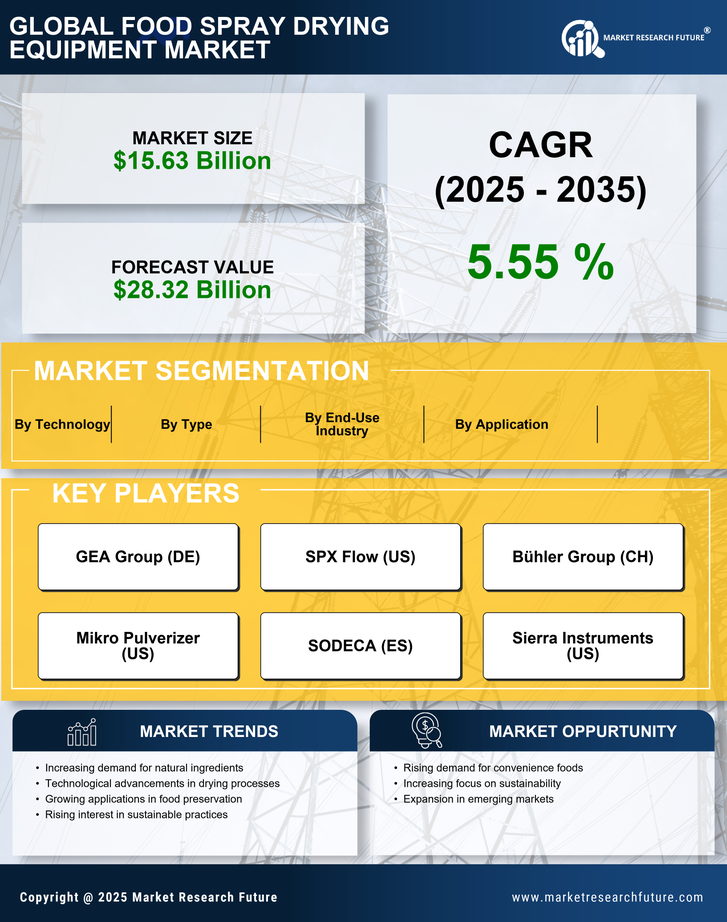

The Food Spray Drying Equipment Market is experiencing a surge in technological innovations that enhance efficiency and product quality. Advanced drying technologies, such as multi-stage spray drying and the integration of automation, are becoming increasingly prevalent. These innovations not only reduce energy consumption but also improve the retention of nutrients and flavors in dried products. As a result, manufacturers are able to produce higher-quality food products that meet consumer expectations. The market for food spray drying equipment is projected to grow at a compound annual growth rate of approximately 6% over the next few years, driven by these technological advancements. This trend indicates a shift towards more sophisticated equipment that can cater to the evolving needs of the food industry.