Growth of the Automotive Sector

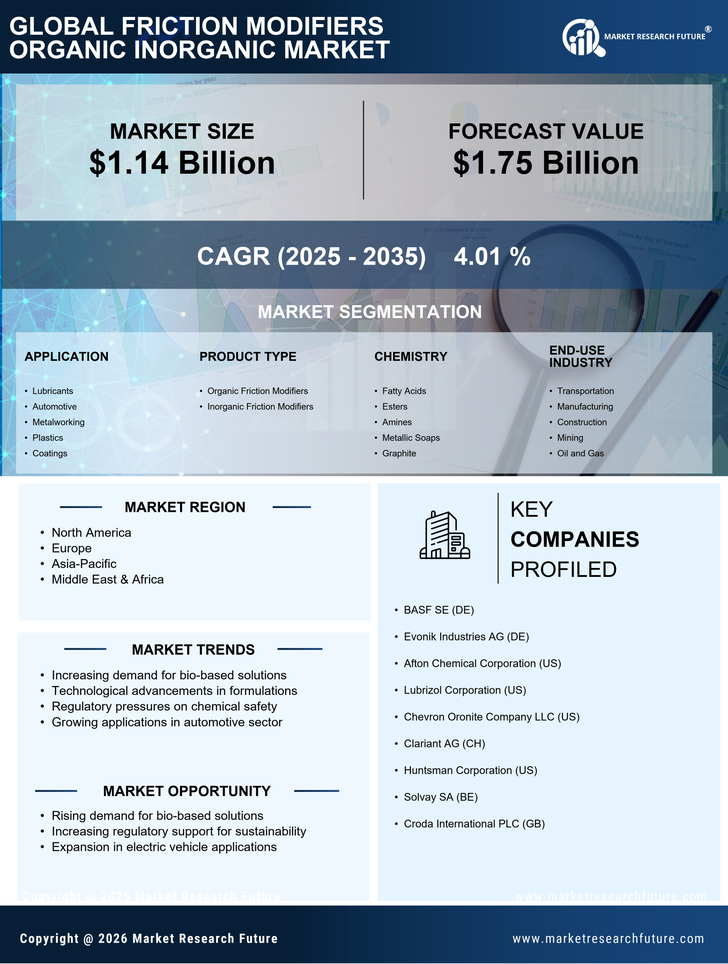

The Friction Modifiers Organic Inorganic Market is closely linked to the growth of the automotive sector. As vehicle manufacturers increasingly focus on enhancing fuel efficiency and reducing emissions, the demand for advanced lubricants containing friction modifiers is on the rise. Recent statistics indicate that the automotive industry is projected to expand at a rate of approximately 4% annually, which directly influences the demand for high-performance lubricants. Friction modifiers are essential in achieving the desired performance characteristics in these lubricants, thereby supporting the automotive industry's objectives. This growth not only drives the demand for friction modifiers but also encourages manufacturers to innovate and develop new formulations that meet the evolving needs of the automotive market.

Expansion of Industrial Applications

The Friction Modifiers Organic Inorganic Market is witnessing an expansion in industrial applications, which is contributing to its growth. Industries such as manufacturing, construction, and mining are increasingly utilizing friction modifiers to enhance the performance of machinery and equipment. The need for improved efficiency and reduced maintenance costs is driving this trend. Market data suggests that the industrial lubricants segment is expected to grow at a compound annual growth rate of around 3% over the next few years. As industries seek to optimize their operations, the demand for effective friction modifiers that can withstand harsh conditions is likely to increase. This expansion into diverse industrial applications not only broadens the market scope but also presents opportunities for innovation and product development within the industry.

Rising Demand for High-Performance Lubricants

The Friction Modifiers Organic Inorganic Market is experiencing a notable increase in demand for high-performance lubricants. This trend is driven by the automotive and industrial sectors, where the need for enhanced efficiency and reduced wear is paramount. According to recent data, the lubricant market is projected to grow at a compound annual growth rate of approximately 3.5% over the next few years. Friction modifiers play a crucial role in improving the performance of these lubricants, thereby contributing to the overall growth of the industry. As manufacturers seek to meet stringent regulatory standards and consumer expectations for sustainability, the incorporation of organic and inorganic friction modifiers becomes increasingly vital. This shift not only enhances product performance but also aligns with the broader industry trend towards environmentally friendly solutions.

Increasing Regulatory Pressure for Environmental Compliance

The Friction Modifiers Organic Inorganic Market is facing increasing regulatory pressure aimed at promoting environmental compliance. Governments and regulatory bodies are implementing stricter guidelines regarding the use of chemicals in various applications, particularly in lubricants and coatings. This regulatory landscape is pushing manufacturers to seek out friction modifiers that are not only effective but also environmentally friendly. Market analysis suggests that the demand for bio-based and biodegradable friction modifiers is likely to rise as companies strive to meet these regulations. The shift towards sustainable practices is expected to reshape product offerings within the industry, leading to a greater emphasis on organic friction modifiers. Consequently, this trend may drive innovation and investment in the development of compliant products, ultimately benefiting the industry as a whole.

Technological Innovations in Friction Modifier Formulations

Technological advancements are significantly shaping the Friction Modifiers Organic Inorganic Market. Innovations in formulation chemistry are leading to the development of more effective friction modifiers that enhance the performance of lubricants and other applications. For instance, the introduction of nanotechnology in friction modifier formulations has shown promise in improving wear resistance and reducing friction. Market data indicates that the adoption of such advanced technologies could potentially increase the efficiency of friction modifiers by up to 20%. As industries continue to prioritize performance and sustainability, the demand for technologically advanced friction modifiers is likely to rise. This trend not only supports the growth of the industry but also encourages further research and development in the field, fostering a competitive landscape.