Growth in Consumer Goods Sector

The consumer goods sector is increasingly incorporating glass filled nylon into products ranging from household appliances to sporting goods. The material's strength and lightweight characteristics make it an attractive choice for manufacturers aiming to enhance product performance while reducing costs. The glass filled nylon market is likely to benefit from this trend, as consumer preferences shift towards durable and high-quality products. Market analysts suggest that the sector could account for a substantial share of the overall demand for glass filled nylon, with projections indicating a steady increase in consumption over the next few years. This growth is indicative of a broader shift towards innovative materials in consumer products.

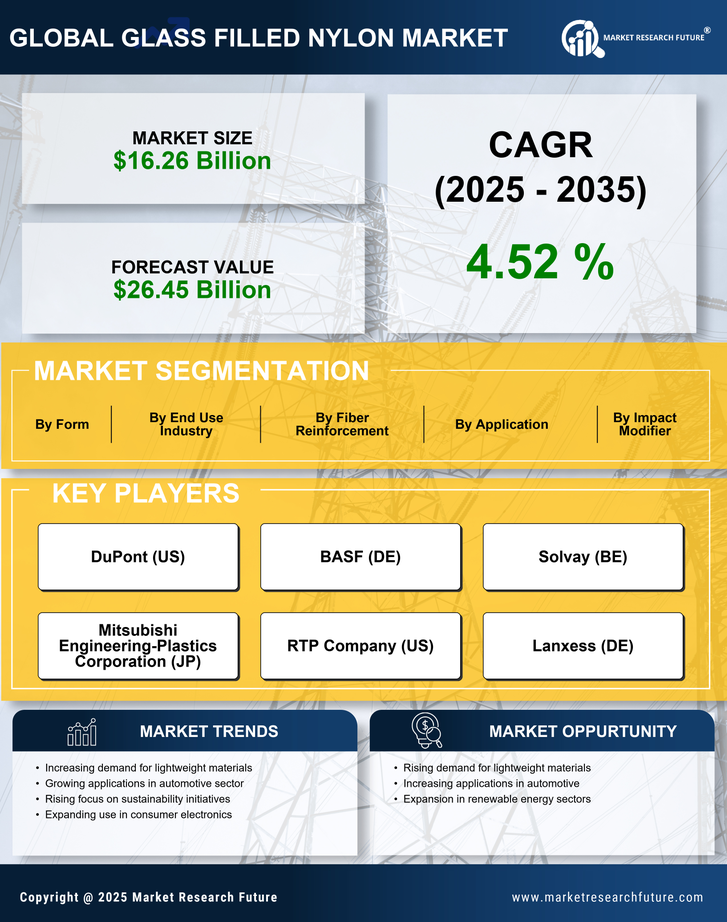

Increasing Focus on Sustainability

The growing emphasis on sustainability is influencing the glass filled nylon market, as manufacturers seek eco-friendly alternatives to traditional materials. The incorporation of recycled glass fibers into nylon formulations is gaining traction, aligning with global sustainability goals. This shift not only reduces environmental impact but also appeals to consumers who prioritize sustainable products. Market trends indicate that the demand for sustainable glass filled nylon solutions is likely to rise, potentially leading to innovations in material formulations and processing techniques. As companies strive to meet regulatory requirements and consumer expectations, the glass filled nylon market may see a significant transformation towards more sustainable practices.

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable increase in the adoption of glass filled nylon due to its lightweight and high-strength properties. This trend is particularly evident in the production of components such as gears, housings, and structural parts, where the material's durability and resistance to wear are paramount. The glass filled nylon market is projected to witness a compound annual growth rate of approximately 5% over the next few years, driven by the need for fuel-efficient vehicles. As manufacturers seek to reduce vehicle weight while maintaining performance, the demand for glass filled nylon is likely to surge, indicating a robust growth trajectory for the market.

Advancements in Manufacturing Technologies

Recent advancements in manufacturing technologies, such as 3D printing and injection molding, are facilitating the production of complex geometries using glass filled nylon. These innovations allow for greater design flexibility and efficiency, which are crucial in industries like aerospace and automotive. The glass filled nylon market is poised to benefit from these technological developments, as they enable manufacturers to produce lightweight and high-performance components with reduced lead times. As these technologies continue to evolve, the market may experience an influx of new applications and increased competition, potentially reshaping the landscape of the glass filled nylon industry.

Expansion in Electrical and Electronics Applications

The electrical and electronics industry is increasingly utilizing glass filled nylon for its excellent electrical insulation properties and thermal stability. Components such as connectors, housings, and circuit boards benefit from the material's ability to withstand high temperatures and provide structural integrity. The glass filled nylon market is expected to grow as the demand for lightweight and durable materials in electronic devices rises. With the proliferation of smart devices and the Internet of Things, the market could see a significant uptick, potentially reaching a valuation of several billion dollars in the coming years. This expansion reflects a broader trend towards miniaturization and efficiency in electronic applications.