Market Growth Projections

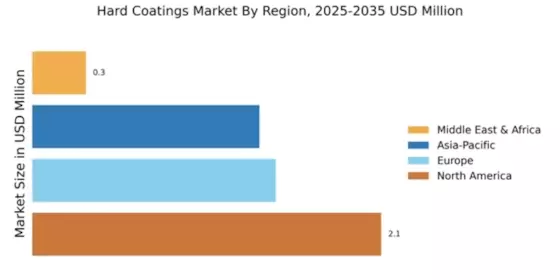

The Global Hard Coating Market Industry is projected to experience substantial growth in the coming years. With a market value of 185.4 USD Million in 2024, the industry is expected to expand significantly, reaching an estimated 2196.3 USD Million by 2035. This growth trajectory indicates a compound annual growth rate of 25.2% from 2025 to 2035. The increasing adoption of hard coatings across various sectors, driven by technological advancements and rising demand for durable products, underpins these projections. As industries continue to prioritize performance and sustainability, the hard coating market is likely to thrive, reflecting broader trends in manufacturing and product development.

Expansion of End-Use Industries

The expansion of end-use industries significantly influences the Global Hard Coating Market Industry. Sectors such as electronics, automotive, and medical devices are experiencing rapid growth, driving the demand for hard coatings. In the electronics industry, the need for protective coatings on components is increasing due to the rising complexity of devices. Additionally, the automotive sector's shift towards electric vehicles necessitates advanced coatings to enhance battery performance and longevity. This expansion is expected to contribute to the market's growth, with forecasts indicating a substantial increase in market value, reaching 2196.3 USD Million by 2035. The interplay between industry growth and hard coating applications presents a promising outlook.

Growing Focus on Energy Efficiency

The Global Hard Coating Market Industry is witnessing a growing focus on energy efficiency, particularly in manufacturing processes. Hard coatings contribute to energy savings by reducing friction and wear in machinery, leading to lower energy consumption. Industries are increasingly recognizing the economic benefits of implementing hard coatings, as they not only enhance product performance but also reduce operational costs. For example, in the aerospace sector, the use of hard coatings on turbine components has demonstrated significant energy savings. This trend aligns with global initiatives aimed at promoting sustainability and reducing carbon footprints, further propelling the demand for hard coatings.

Rising Demand for Durable Coatings

The Global Hard Coating Market Industry experiences a notable increase in demand for durable coatings across various sectors, including automotive, aerospace, and electronics. As industries seek to enhance the longevity and performance of their products, hard coatings provide a viable solution. For instance, the automotive sector is increasingly adopting hard coatings to improve scratch resistance and reduce wear on components. This trend is expected to contribute to the market's growth, with projections indicating a market value of 185.4 USD Million in 2024. The emphasis on durability aligns with the industry's shift towards sustainable practices, further driving the adoption of hard coatings.

Regulatory Support for Advanced Coatings

Regulatory support for advanced coatings is emerging as a key driver in the Global Hard Coating Market Industry. Governments worldwide are implementing regulations that encourage the use of environmentally friendly and high-performance coatings. This support fosters innovation and investment in hard coating technologies, as manufacturers seek to comply with stringent environmental standards. For instance, regulations promoting the use of low-VOC coatings are likely to drive the development of hard coatings that meet these criteria. As a result, the market is poised for growth, with stakeholders increasingly recognizing the importance of regulatory compliance in enhancing product offerings.

Technological Advancements in Coating Processes

Technological advancements play a crucial role in shaping the Global Hard Coating Market Industry. Innovations in coating processes, such as physical vapor deposition and chemical vapor deposition, enhance the efficiency and effectiveness of hard coatings. These technologies allow for the application of coatings with superior properties, including increased hardness and improved adhesion. As manufacturers adopt these advanced techniques, the quality of hard coatings improves, leading to broader applications in industries such as medical devices and tooling. The ongoing evolution of coating technologies is likely to sustain the market's growth trajectory, with a projected compound annual growth rate of 25.2% from 2025 to 2035.