Regulatory Compliance and Standards

The implementation of stringent regulations and standards regarding corrosion protection in various industries appears to be influencing the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. Governments and regulatory bodies are increasingly mandating the use of high-performance coatings to ensure safety and longevity in infrastructure and industrial applications. This regulatory landscape is likely to drive demand for advanced rust stabilizers that meet these compliance requirements. As industries strive to adhere to these regulations, the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market may experience a surge in demand, as companies seek to avoid penalties and ensure operational efficiency.

Increasing Infrastructure Development

The ongoing expansion of infrastructure projects worldwide appears to be a primary driver for the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. As nations invest in roads, bridges, and buildings, the demand for protective coatings that enhance durability and longevity is likely to rise. The market for protective coatings is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years, indicating a robust demand for high-performance solutions. This trend suggests that the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market will benefit significantly from increased infrastructure spending, as these coatings provide essential protection against corrosion and environmental degradation.

Growing Demand from Emerging Economies

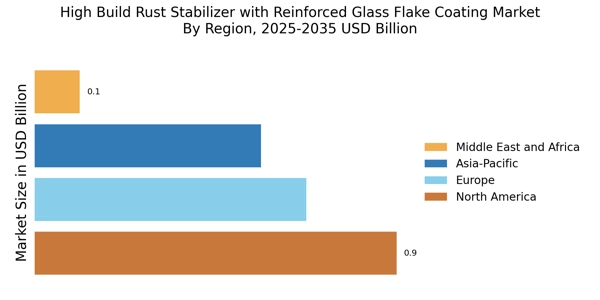

Emerging economies are witnessing rapid industrialization and urbanization, which seems to be creating a substantial demand for protective coatings, including those in the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. As these regions develop their infrastructure and industrial capabilities, the need for effective rust prevention solutions is likely to increase. The market in Asia-Pacific, for instance, is projected to grow significantly, driven by rising construction activities and manufacturing output. This trend indicates that the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market could see considerable growth opportunities as emerging economies continue to expand their industrial base.

Rising Awareness of Corrosion Prevention

There is a growing awareness regarding the detrimental effects of corrosion on various structures and equipment, which seems to be propelling the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. Industries such as oil and gas, marine, and construction are increasingly recognizing the importance of investing in rust prevention solutions. The High Build Rust Stabilizer with Reinforced Glass Flake Coating is expected to reach USD 30 billion by 2026, highlighting the potential for growth in the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. This heightened awareness is likely to drive demand for advanced coatings that offer superior protection and longevity, thereby enhancing the overall market landscape.

Technological Innovations in Coating Solutions

Technological advancements in coating formulations and application techniques appear to be a significant driver for the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market. Innovations such as the development of eco-friendly coatings and improved application methods are likely to enhance the performance and efficiency of rust stabilizers. The introduction of smart coatings that can self-repair or provide real-time monitoring of corrosion levels may further stimulate market growth. As industries seek to adopt more efficient and sustainable solutions, the High Build Rust Stabilizer with Reinforced Glass Flake Coating Market is poised to benefit from these technological innovations, potentially leading to increased market penetration.