Expansion of the Construction Sector

The High Temperature Insulation Wool Market is poised for growth due to the expansion of the construction sector, particularly in commercial and industrial buildings. As new construction projects emerge, there is an increasing need for effective insulation solutions that can withstand high temperatures. High temperature insulation wool is becoming a preferred choice for builders and contractors due to its excellent thermal properties and fire resistance. The construction industry is projected to grow steadily, with investments in infrastructure and industrial facilities driving demand for high temperature insulation materials. This expansion is likely to create new opportunities for manufacturers and suppliers within the high temperature insulation wool market.

Growth in Energy Efficiency Regulations

The High Temperature Insulation Wool Market is significantly influenced by the tightening of energy efficiency regulations across various sectors. Governments and regulatory bodies are increasingly mandating the use of high-performance insulation materials to reduce energy consumption and greenhouse gas emissions. For instance, regulations in the construction and manufacturing sectors are pushing for the adoption of materials that meet stringent thermal performance standards. This regulatory landscape is expected to drive the demand for high temperature insulation wool, as it offers excellent thermal resistance and contributes to energy savings. The market is likely to see a surge in adoption as compliance with these regulations becomes essential for operational viability.

Increased Focus on Sustainable Practices

The High Temperature Insulation Wool Market is witnessing a shift towards sustainable practices, driven by both consumer preferences and corporate responsibility initiatives. Companies are increasingly seeking insulation materials that not only provide thermal efficiency but also align with sustainability goals. High temperature insulation wool, often made from recyclable materials, offers an eco-friendly alternative to traditional insulation options. This trend is further supported by the growing awareness of environmental issues and the need for sustainable construction practices. As businesses strive to reduce their carbon footprint, the demand for sustainable insulation solutions is expected to rise, thereby positively impacting the high temperature insulation wool market.

Rising Demand in Industrial Applications

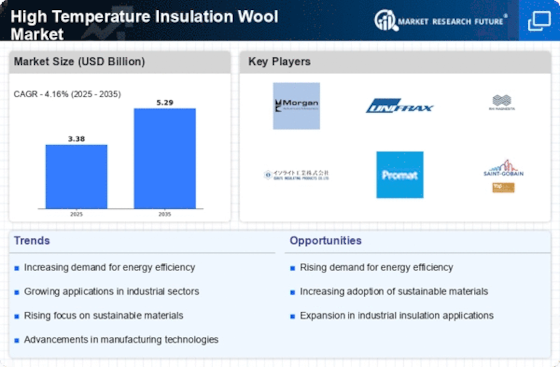

The High Temperature Insulation Wool Market is experiencing a notable increase in demand driven by various industrial applications. Industries such as petrochemicals, power generation, and metal processing are increasingly utilizing high temperature insulation wool for its superior thermal resistance and energy efficiency. According to recent data, the insulation market is projected to grow at a compound annual growth rate of approximately 6% over the next few years. This growth is largely attributed to the need for energy conservation and the reduction of operational costs in high-temperature environments. As industries strive to enhance their operational efficiency, the adoption of high temperature insulation wool becomes a strategic choice, thereby propelling the market forward.

Technological Innovations in Insulation Materials

The High Temperature Insulation Wool Market is benefiting from ongoing technological innovations that enhance the performance and application of insulation materials. Recent advancements in manufacturing processes have led to the development of more efficient and durable high temperature insulation wool products. These innovations not only improve thermal performance but also expand the range of applications in industries such as aerospace, automotive, and manufacturing. The introduction of lightweight and flexible insulation solutions is particularly noteworthy, as they cater to the evolving needs of modern industrial applications. As technology continues to advance, the market is poised for growth, with new products entering the market that meet the demands of high-performance insulation.