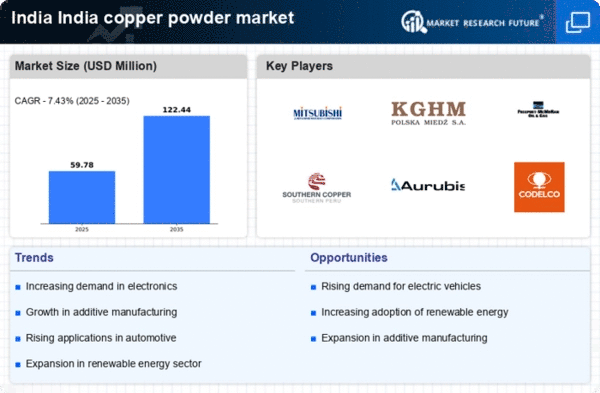

The copper powder market in India is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as Mitsubishi Materials Corporation (Japan), KGHM Polska Miedz S.A. (Poland), and Jiangxi Copper Corporation Limited (China) are actively pursuing strategies that enhance their market positioning. Mitsubishi Materials Corporation (Japan) focuses on technological advancements in production processes, aiming to improve efficiency and reduce environmental impact. KGHM Polska Miedz S.A. (Poland) emphasizes regional expansion and supply chain optimization, which allows for better responsiveness to local market demands. Jiangxi Copper Corporation Limited (China) is investing in digital transformation initiatives to streamline operations and enhance product quality, thereby contributing to a more competitive environment.The business tactics employed by these companies reflect a moderately fragmented market structure, where localized manufacturing and supply chain optimization play crucial roles. The collective influence of these key players fosters a dynamic competitive atmosphere, as they strive to differentiate themselves through innovation and operational excellence. This competitive structure encourages ongoing investment in technology and sustainability, which are becoming essential for maintaining market relevance.

In August KGHM Polska Miedz S.A. (Poland) announced a strategic partnership with a local Indian firm to enhance its copper powder production capabilities. This collaboration is expected to leverage local expertise and resources, thereby optimizing production efficiency and reducing costs. Such strategic moves are indicative of KGHM's commitment to strengthening its foothold in the Indian market while addressing the growing demand for high-quality copper powder.

In September Jiangxi Copper Corporation Limited (China) unveiled a new digital platform aimed at improving supply chain transparency and customer engagement. This initiative is significant as it aligns with the broader trend of digitalization within the industry, potentially leading to enhanced customer satisfaction and operational efficiency. By adopting advanced technologies, Jiangxi Copper Corporation Limited is positioning itself as a forward-thinking leader in the copper powder market.

In October Mitsubishi Materials Corporation (Japan) launched a new line of eco-friendly copper powders designed for use in various applications, including electronics and automotive sectors. This product line not only reflects the company's commitment to sustainability but also addresses the increasing demand for environmentally friendly materials. The introduction of such innovative products is likely to enhance Mitsubishi's competitive edge in a market that is progressively leaning towards sustainable practices.

As of November the competitive trends in the copper powder market are increasingly defined by digitalization, sustainability, and strategic alliances. Companies are recognizing the importance of forming partnerships to enhance their technological capabilities and market reach. The shift from price-based competition to a focus on innovation, technology, and supply chain reliability is becoming more pronounced. This evolution suggests that future competitive differentiation will hinge on the ability to adapt to changing market dynamics and consumer preferences.