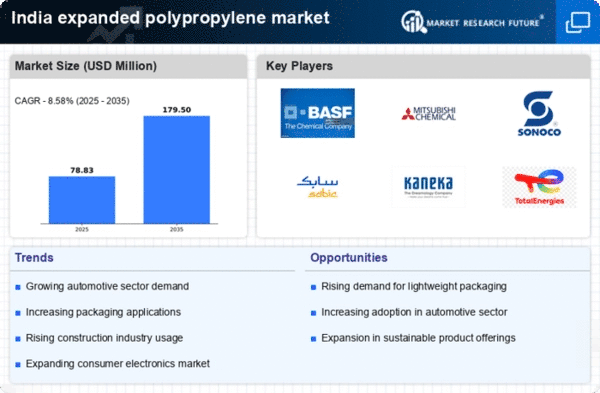

The expanded polypropylene market in India is characterized by a dynamic competitive landscape, driven by increasing demand across various sectors such as automotive, packaging, and consumer goods. Key players are actively engaging in strategies that emphasize innovation, sustainability, and regional expansion. For instance, BASF SE (Germany) has been focusing on enhancing its product portfolio through sustainable solutions, while

Mitsubishi Chemical Corporation (Japan) is investing in advanced manufacturing technologies to improve efficiency and reduce environmental impact. These strategic initiatives not only bolster their market positions but also contribute to a more competitive environment, as companies strive to differentiate themselves through unique offerings and operational excellence.In terms of business tactics, localizing manufacturing and optimizing supply chains appear to be pivotal for success in this market. The competitive structure is moderately fragmented, with several players vying for market share. However, the influence of major companies like Sonoco Products Company (US) and SABIC (Saudi Arabia) is substantial, as they leverage their extensive networks and resources to enhance their operational capabilities. This collective presence of key players fosters a competitive atmosphere where innovation and efficiency are paramount.

In October Sonoco Products Company (US) announced the launch of a new line of eco-friendly expanded polypropylene products aimed at the packaging sector. This strategic move underscores the company's commitment to sustainability and positions it favorably in a market increasingly driven by environmental considerations. By aligning its product offerings with consumer preferences for sustainable materials, Sonoco is likely to enhance its competitive edge and attract a broader customer base.

In September SABIC (Saudi Arabia) unveiled a partnership with a leading automotive manufacturer to develop lightweight expanded polypropylene components for electric vehicles. This collaboration not only highlights SABIC's focus on innovation but also reflects the growing trend towards lightweight materials in the automotive industry. Such strategic alliances are crucial as they enable companies to tap into new markets and enhance their technological capabilities, thereby strengthening their market position.

In August JSP Corporation (Japan) expanded its production capacity in India to meet the rising demand for expanded polypropylene in the automotive and packaging sectors. This expansion is indicative of JSP's proactive approach to capitalize on market growth opportunities. By increasing its manufacturing capabilities, JSP is likely to improve its supply chain efficiency and responsiveness, which are critical factors in maintaining competitiveness in a rapidly evolving market.

As of November current competitive trends in the expanded polypropylene market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are playing a significant role in shaping the landscape, as companies collaborate to enhance their innovation capabilities and market reach. Looking ahead, it is anticipated that competitive differentiation will evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability. This shift underscores the importance of adaptability and forward-thinking strategies in navigating the complexities of the market.