Regulatory Support

Regulatory support is emerging as a vital driver for the India Rigid Plastic Packaging Market. The Indian government has implemented various policies aimed at promoting sustainable packaging practices and reducing plastic waste. Initiatives such as the Plastic Waste Management Rules encourage manufacturers to adopt eco-friendly materials and practices. Compliance with these regulations is becoming increasingly important for companies seeking to maintain their market position. Furthermore, the government is likely to introduce incentives for businesses that invest in sustainable packaging solutions, thereby fostering innovation and growth within the industry. As regulatory frameworks evolve, they are expected to create a conducive environment for the expansion of the rigid plastic packaging market in India.

Consumer Preferences

Shifting consumer preferences are significantly influencing the India Rigid Plastic Packaging Market. As consumers become more health-conscious and quality-driven, there is a growing demand for packaging that ensures product safety and freshness. Rigid plastic packaging is favored for its ability to provide airtight seals and protect products from contamination. Additionally, the convenience factor associated with rigid plastic containers, such as ease of handling and storage, is appealing to consumers. Market Research Future indicates that approximately 60% of consumers prefer products packaged in rigid plastic due to its durability and reusability. This trend is likely to drive manufacturers to innovate and enhance their packaging solutions, aligning with consumer expectations and preferences.

Diverse Applications

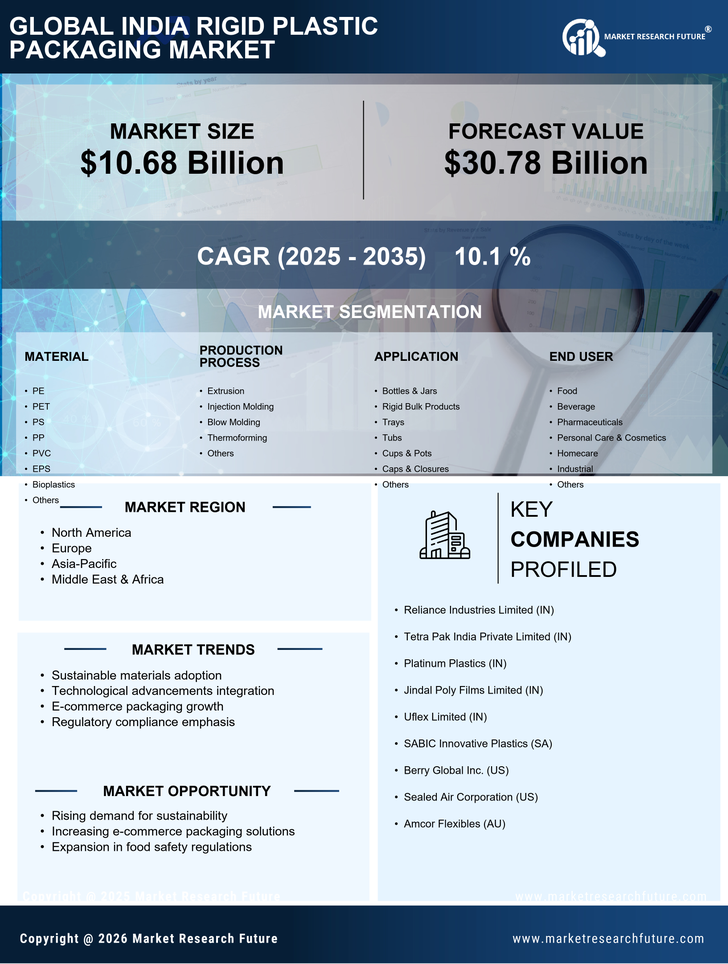

The versatility of rigid plastic packaging is a significant driver for the India Rigid Plastic Packaging Market. This packaging format is utilized across various sectors, including food and beverages, pharmaceuticals, and consumer goods. The food and beverage sector, in particular, is experiencing robust growth, with the market for rigid plastic containers projected to reach USD 10 billion by 2025. The ability of rigid plastic packaging to preserve product integrity and extend shelf life is highly valued by manufacturers. Additionally, the pharmaceutical industry is increasingly adopting rigid plastic packaging for its lightweight and tamper-evident features. This diverse applicability not only enhances market penetration but also fosters innovation in packaging designs, catering to the specific needs of different industries.

Sustainability Initiatives

The increasing emphasis on sustainability is a pivotal driver for the India Rigid Plastic Packaging Market. As consumers become more environmentally conscious, companies are compelled to adopt eco-friendly packaging solutions. This shift is evident in the growing demand for recyclable and biodegradable materials. According to recent data, the market for sustainable packaging in India is projected to reach USD 20 billion by 2025, indicating a robust growth trajectory. Companies are investing in innovative materials and processes that minimize environmental impact, thereby enhancing their brand image and meeting regulatory requirements. The focus on reducing plastic waste and promoting circular economy principles is likely to further propel the demand for rigid plastic packaging solutions that align with sustainability goals.

Technological Advancements

Technological advancements play a crucial role in shaping the India Rigid Plastic Packaging Market. Innovations in manufacturing processes, such as injection molding and blow molding, have led to enhanced efficiency and reduced production costs. Furthermore, the integration of automation and smart technologies in packaging lines is streamlining operations and improving product quality. The market is witnessing a surge in the adoption of advanced materials that offer better barrier properties and durability. For instance, the introduction of multi-layered packaging solutions is gaining traction, catering to the needs of various sectors, including food and beverages. As technology continues to evolve, it is expected that the India Rigid Plastic Packaging Market will experience significant growth, driven by enhanced product offerings and operational efficiencies.