Sustainability Initiatives in Induction Furnace Market

Sustainability initiatives are becoming a pivotal driver in the Induction Furnace Market. As industries face increasing pressure to reduce carbon footprints, induction furnaces, known for their energy efficiency, are gaining traction. The ability of induction furnaces to utilize recycled materials effectively aligns with the global shift towards sustainable manufacturing practices. Recent statistics indicate that induction furnaces can achieve energy savings of up to 30% compared to traditional melting methods. This not only contributes to lower operational costs but also supports environmental goals. Consequently, manufacturers are increasingly investing in induction furnace technology to meet sustainability targets, thereby propelling growth in the Induction Furnace Market. The emphasis on eco-friendly production methods is likely to shape future market dynamics.

Technological Advancements in Induction Furnace Market

The Induction Furnace Market is experiencing a notable transformation due to rapid technological advancements. Innovations in induction heating technology, such as the development of high-frequency induction furnaces, are enhancing efficiency and reducing energy consumption. These advancements are projected to drive the market, as manufacturers increasingly seek to optimize production processes. According to recent data, the adoption of advanced induction furnaces has led to a reduction in operational costs by approximately 20%. Furthermore, the integration of automation and smart technologies is likely to improve precision in metal melting processes, thereby attracting more players to the Induction Furnace Market. As industries strive for higher productivity and lower environmental impact, the demand for technologically advanced induction furnaces is expected to rise significantly.

Market Expansion in Emerging Economies for Induction Furnace Market

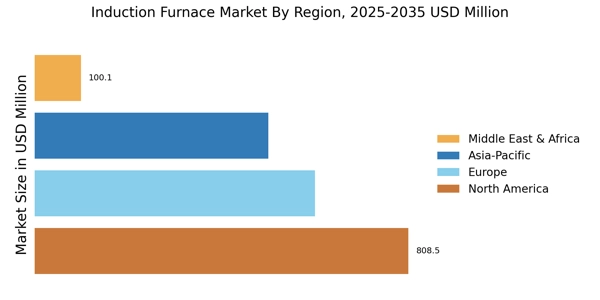

The Induction Furnace Market is witnessing substantial growth opportunities in emerging economies. Rapid industrialization and urbanization in regions such as Asia-Pacific and Latin America are driving demand for efficient metal processing solutions. As these economies develop, the need for advanced manufacturing technologies, including induction furnaces, is becoming more pronounced. Market data suggests that the Asia-Pacific region alone is expected to account for over 40% of the total market share by 2026. This growth is fueled by increasing investments in infrastructure and manufacturing sectors, which are likely to adopt induction furnace technology for its efficiency and cost-effectiveness. The expansion of the Induction Furnace Market in these regions presents a significant opportunity for manufacturers to tap into new customer bases.

Rising Demand for Lightweight Materials in Induction Furnace Market

The rising demand for lightweight materials across various industries is influencing the Induction Furnace Market. As sectors such as automotive and aerospace prioritize weight reduction to enhance fuel efficiency, the need for advanced metal processing techniques becomes critical. Induction furnaces are particularly well-suited for melting and processing lightweight alloys, which are increasingly utilized in these applications. Market analysis indicates that the demand for lightweight materials is projected to grow at a CAGR of 5% over the next five years. This trend is likely to drive the adoption of induction furnaces, as manufacturers seek to meet the evolving requirements of their clients. The Induction Furnace Market stands to benefit from this shift, as it aligns with the broader trend of innovation in material science.

Increased Investment in Research and Development in Induction Furnace Market

Increased investment in research and development (R&D) is emerging as a crucial driver for the Induction Furnace Market. As competition intensifies, manufacturers are allocating more resources to innovate and enhance the performance of induction furnaces. This focus on R&D is likely to lead to the development of next-generation induction heating technologies that offer improved efficiency and versatility. Recent reports indicate that R&D spending in the manufacturing sector is expected to rise by 10% annually, reflecting a commitment to technological advancement. Such investments not only foster innovation but also enable companies to respond effectively to changing market demands. The emphasis on R&D within the Induction Furnace Market is anticipated to yield new products that cater to diverse industrial applications.