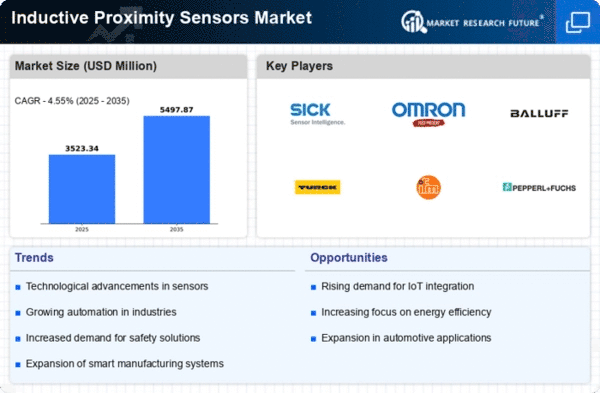

Market Growth Projections

The Global Inductive Proximity Sensors Market Industry is poised for substantial growth, with projections indicating a market value of 3.37 USD Billion in 2024 and an anticipated increase to 5.5 USD Billion by 2035. This growth trajectory suggests a robust demand for inductive proximity sensors, driven by various factors such as automation, safety requirements, and technological advancements. The market is expected to experience a compound annual growth rate (CAGR) of 4.55% from 2025 to 2035, reflecting the ongoing evolution and integration of these sensors across multiple industries.

Rising Automation in Industries

The Global Inductive Proximity Sensors Market Industry is experiencing a surge in demand due to the increasing automation across various sectors. Industries such as manufacturing, automotive, and packaging are adopting automated solutions to enhance efficiency and reduce operational costs. For instance, the integration of inductive proximity sensors in assembly lines allows for precise detection of metal objects, thereby streamlining production processes. This trend is expected to contribute significantly to the market, with projections indicating a market value of 3.37 USD Billion in 2024, highlighting the growing reliance on automation technologies.

Expansion of the Automotive Sector

The expansion of the automotive sector is a significant driver for the Global Inductive Proximity Sensors Market Industry. As electric vehicles and advanced driver-assistance systems become more prevalent, the demand for reliable sensing solutions is increasing. Inductive proximity sensors are essential in various automotive applications, including parking assistance and collision avoidance systems. The automotive industry's growth is expected to propel the market value, with projections indicating a rise to 5.5 USD Billion by 2035. This trend underscores the critical role of inductive sensors in enhancing vehicle safety and functionality.

Increased Focus on Energy Efficiency

The Global Inductive Proximity Sensors Market Industry is benefiting from the increased focus on energy efficiency across industries. Organizations are seeking solutions that not only enhance operational efficiency but also reduce energy consumption. Inductive proximity sensors contribute to energy savings by optimizing machine performance and minimizing waste. For instance, their application in smart manufacturing systems allows for real-time monitoring and control, leading to significant energy reductions. This growing emphasis on sustainability is likely to drive market growth, aligning with global initiatives aimed at reducing carbon footprints.

Growing Demand for Safety and Security

Safety and security concerns are driving the Global Inductive Proximity Sensors Market Industry as organizations prioritize the protection of personnel and assets. Inductive proximity sensors play a crucial role in safety applications, such as detecting the presence of objects in hazardous areas or ensuring proper machine operation. For example, in the automotive sector, these sensors are utilized in safety systems to prevent accidents. As industries increasingly adopt safety regulations, the demand for these sensors is likely to rise, contributing to an anticipated market growth to 5.5 USD Billion by 2035.

Technological Advancements in Sensor Technology

Technological advancements are significantly influencing the Global Inductive Proximity Sensors Market Industry. Innovations in sensor technology, such as enhanced sensitivity and miniaturization, are enabling the development of more efficient and versatile sensors. These advancements allow for improved performance in various applications, including robotics and automation. For instance, the introduction of sensors with higher detection ranges and faster response times is likely to attract a broader customer base. As these technologies evolve, the market is projected to grow at a CAGR of 4.55% from 2025 to 2035, reflecting the ongoing evolution in sensor capabilities.