Increased Focus on Sustainability

Sustainability is becoming a central theme in the Industrial Maintenance Management Software Market. Organizations are increasingly aware of their environmental impact and are seeking ways to reduce waste and energy consumption. Maintenance management software plays a crucial role in this endeavor by optimizing maintenance schedules and extending the lifespan of equipment. By implementing effective maintenance practices, companies can reduce their carbon footprint and contribute to sustainability goals. Recent data suggests that organizations that adopt sustainable maintenance practices can achieve a 20% reduction in energy usage. As industries strive to align with sustainability initiatives, the demand for maintenance management software that supports these objectives is expected to grow. This trend indicates a shift towards environmentally responsible practices within the Industrial Maintenance Management Software Market.

Growing Importance of Data Analytics

The growing importance of data analytics is reshaping the Industrial Maintenance Management Software Market. Organizations are increasingly leveraging data to drive maintenance strategies and improve operational performance. Advanced analytics tools enable companies to analyze historical maintenance data, identify trends, and make informed decisions regarding asset management. This data-driven approach not only enhances maintenance efficiency but also contributes to cost savings. Recent findings indicate that organizations utilizing data analytics in their maintenance processes can achieve a 15% reduction in maintenance costs. As the emphasis on data-driven decision-making continues to rise, the demand for maintenance management software equipped with robust analytics capabilities is likely to increase. This trend underscores the critical role of data in optimizing maintenance practices within the Industrial Maintenance Management Software Market.

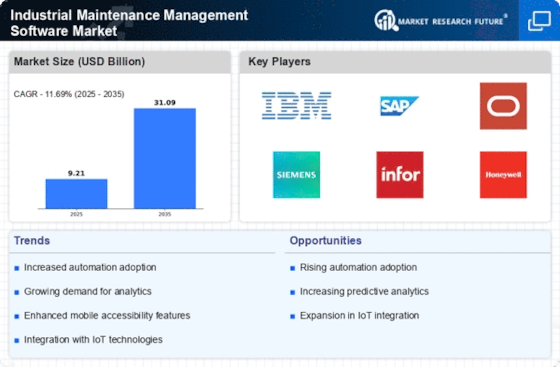

Rising Demand for Operational Efficiency

The Industrial Maintenance Management Software Market is experiencing a notable surge in demand for operational efficiency. Organizations are increasingly recognizing the need to streamline maintenance processes to reduce downtime and enhance productivity. According to recent data, companies that implement effective maintenance management solutions can achieve up to a 30% reduction in operational costs. This trend is driven by the necessity to maintain competitive advantage in a rapidly evolving industrial landscape. As businesses strive to optimize their resources, the adoption of maintenance management software becomes a strategic imperative. The ability to monitor equipment health and schedule maintenance proactively is reshaping how industries approach asset management. Consequently, the Industrial Maintenance Management Software Market is poised for substantial growth as organizations prioritize efficiency and reliability in their operations.

Regulatory Compliance and Safety Standards

The Industrial Maintenance Management Software Market is also being driven by the need for regulatory compliance and adherence to safety standards. Industries such as manufacturing, energy, and transportation are subject to stringent regulations that mandate regular maintenance and safety checks. Failure to comply with these regulations can result in severe penalties and operational disruptions. As a result, organizations are increasingly investing in maintenance management software to ensure compliance and enhance safety protocols. The software facilitates documentation and reporting, making it easier for companies to demonstrate adherence to regulatory requirements. This focus on compliance not only mitigates risks but also fosters a culture of safety within organizations. Consequently, the Industrial Maintenance Management Software Market is likely to see continued growth as businesses prioritize regulatory adherence and workplace safety.

Technological Advancements in Maintenance Solutions

Technological advancements are significantly influencing the Industrial Maintenance Management Software Market. Innovations such as artificial intelligence and machine learning are being integrated into maintenance solutions, enabling predictive analytics and real-time monitoring. These technologies allow organizations to anticipate equipment failures before they occur, thereby minimizing unplanned downtime. Recent studies indicate that predictive maintenance can reduce maintenance costs by up to 25%, highlighting the financial benefits of adopting advanced software solutions. As industries increasingly embrace digital transformation, the demand for sophisticated maintenance management tools is expected to rise. This shift towards technology-driven maintenance practices is likely to propel the Industrial Maintenance Management Software Market forward, as companies seek to leverage data for improved decision-making and operational performance.

Leave a Comment