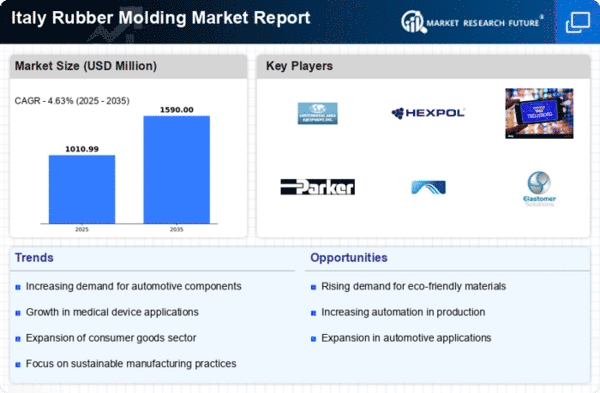

The rubber molding market in Italy is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as Continental AG (DE), Hexpol AB (SE), and Trelleborg AB (SE) are actively pursuing strategies that emphasize technological advancements and regional expansion. For instance, Continental AG (DE) has focused on enhancing its product offerings through research and development, which appears to be a critical driver of its competitive positioning. Meanwhile, Hexpol AB (SE) has been investing in sustainable practices, indicating a shift towards eco-friendly production methods that resonate with current market demands. Collectively, these strategies suggest a market that is not only competitive but also evolving towards more sustainable and innovative practices.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. This approach is particularly relevant in a moderately fragmented market where agility can provide a competitive edge. The presence of major players like Parker Hannifin Corporation (US) and Freudenberg Group (DE) further influences the market structure, as their operational efficiencies and strategic initiatives set benchmarks for smaller firms. The collective influence of these key players fosters a dynamic environment where innovation and responsiveness are paramount.

In October Trelleborg AB (SE) announced a strategic partnership with a leading automotive manufacturer to develop advanced rubber components aimed at enhancing vehicle performance. This collaboration not only underscores Trelleborg's commitment to innovation but also positions the company to leverage the growing demand for high-performance automotive parts. The strategic importance of this partnership lies in its potential to expand Trelleborg's market share while aligning with industry trends towards enhanced vehicle efficiency.

In September Parker Hannifin Corporation (US) unveiled a new line of eco-friendly rubber products designed to meet stringent environmental regulations. This initiative reflects a broader trend within the industry towards sustainability, as companies seek to minimize their environmental footprint. The introduction of these products is likely to enhance Parker Hannifin's competitive advantage, particularly among environmentally conscious consumers and businesses.

In August Hexpol AB (SE) expanded its manufacturing capabilities in Italy by investing €10 million in a new facility dedicated to producing high-performance rubber compounds. This expansion not only signifies Hexpol's commitment to meeting increasing demand but also enhances its operational capacity. The strategic importance of this investment lies in its potential to improve supply chain efficiency and reduce production costs, thereby strengthening Hexpol's competitive position in the market.

As of November the rubber molding market is witnessing trends that emphasize digitalization, sustainability, and the integration of AI technologies. These trends are reshaping competitive dynamics, as companies increasingly form strategic alliances to enhance their technological capabilities and market reach. The shift from price-based competition to a focus on innovation and supply chain reliability is becoming evident, suggesting that future competitive differentiation will hinge on the ability to adapt to these evolving market demands.