Growth in Consumer Electronics

The Low Density Polyethylene LDPE Foams Market is benefiting from the expansion of the consumer electronics sector. As technology advances, the production of electronic devices continues to rise, leading to an increased need for protective packaging solutions. LDPE foams are extensively used in the packaging of electronics due to their excellent shock absorption and insulation properties. The consumer electronics market is expected to grow at a CAGR of around 5% over the next few years, which could further bolster the demand for LDPE foams. This growth suggests that manufacturers in the LDPE foams market will likely find ample opportunities as they cater to the evolving needs of the electronics industry.

Rising Demand in Packaging Sector

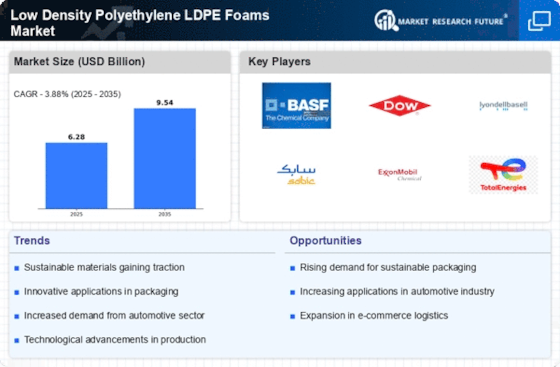

The Low Density Polyethylene LDPE Foams Market is experiencing a notable surge in demand, particularly within the packaging sector. LDPE foams are favored for their lightweight and cushioning properties, making them ideal for protecting fragile items during shipping. The packaging industry is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5% over the next few years, which is likely to drive the consumption of LDPE foams. As e-commerce continues to expand, the need for effective packaging solutions becomes increasingly critical. This trend suggests that the LDPE foams market will benefit significantly from the packaging sector's growth, as manufacturers seek materials that offer both protection and sustainability.

Technological Innovations in Production

The Low Density Polyethylene LDPE Foams Market is experiencing a wave of technological innovations that enhance production efficiency and product quality. Advances in manufacturing processes, such as extrusion and molding techniques, are enabling the production of LDPE foams with improved properties, including enhanced durability and flexibility. These innovations are expected to lead to a reduction in production costs by approximately 10% over the next few years, making LDPE foams more accessible to various industries. As manufacturers adopt these technologies, the market is likely to see an increase in the variety of applications for LDPE foams, further driving demand and expanding market opportunities.

Increased Focus on Lightweight Materials

The Low Density Polyethylene LDPE Foams Market is witnessing a shift towards lightweight materials across various applications. Industries such as automotive and construction are increasingly adopting LDPE foams due to their lightweight nature, which contributes to improved fuel efficiency and reduced energy consumption. For instance, the automotive sector is projected to see a rise in the use of lightweight materials by approximately 20% in the coming years. This trend indicates a growing preference for materials that enhance performance while minimizing environmental impact. Consequently, the demand for LDPE foams is likely to increase as manufacturers prioritize lightweight solutions in their product offerings.

Sustainability and Recycling Initiatives

The Low Density Polyethylene LDPE Foams Market is increasingly influenced by sustainability and recycling initiatives. As environmental concerns gain prominence, manufacturers are exploring eco-friendly alternatives and recycling methods for LDPE foams. The push for sustainable packaging solutions is expected to drive innovation within the industry, with a projected increase in the use of recycled materials by approximately 15% in the next few years. This trend indicates a shift towards more responsible production practices, which may enhance the market appeal of LDPE foams. Consequently, companies that prioritize sustainability are likely to gain a competitive edge in the LDPE foams market.

.png)