Top Industry Leaders in the Low-density Polyethylene Market

Low-density polyethylene (LDPE), boasting remarkable flexibility and resilience, finds its way into an astonishing range of everyday products, from squeezable bottles to food wraps to flexible pipes. The market itself, however, is far from pliable, pulsating with fierce competition as diverse as the applications it serves. Understanding this dynamic landscape requires a closer look at the strategies shaping dominance, the factors influencing market share, and the ever-evolving tapestry of recent developments.

Competitive Strategies Molding the Market:

Diversification and Specialization: Major players like ExxonMobil and Dow are expanding their portfolios, catering to niche applications in industries like healthcare and high-performance packaging. Meanwhile, regional players like Sinopec are carving out unique spaces by specializing in cost-effective production methods or recycled LDPE offerings.

Technological Leap: Innovation is the key to unlocking new possibilities. Companies like Chevron Phillips Chemical and SABIC are investing heavily in advanced reactor technologies, catalyst optimization, and co-polymer development, leading to improved processing efficiency and product performance.

Sustainability Focus: Green credentials are becoming a crucial differentiator. Borealis and LyondellBasell are leading the charge with bio-based LDPE, improved recyclability initiatives, and carbon footprint reduction programs, appealing to environmentally conscious consumers and brands.

Cost Optimization and Efficiency: Optimizing production processes and logistics is key in a price-sensitive market. Companies like Westlake Chemical and Formosa Plastics are investing in automation, digitalization, and strategic sourcing, offering customers competitive pricing and reliable supply.

Strategic Partnerships and Acquisitions: Collaborations and mergers are accelerating innovation and market reach. Recent examples include the partnership between ExxonMobil and Saudi Aramco to build a giant LDPE production facility in Saudi Arabia and the acquisition of Nexeo Plastics by Westlake Chemical, strengthening their hold on the North American market.

Factors Shaping Market Share:

Product Quality and Consistency: Consistent delivery of LDPE with desired properties like clarity, strength, and sealability is paramount for customer satisfaction and brand loyalty.

Cost Competitiveness: Efficient production processes, access to low-cost feedstock, and optimized supply chains play a crucial role in winning price-sensitive contracts.

Customer Service and Technical Support: Proactive support, customized solutions, and technical expertise in processing and application development differentiate players in a crowded market.

Geographical Presence: Being present in key LDPE-consuming regions and having strong local distribution networks are vital for capturing market share.

Sustainability Credentials: Environmental friendliness and circularity practices are becoming increasingly important, with customers favoring companies with a strong commitment to green solutions.

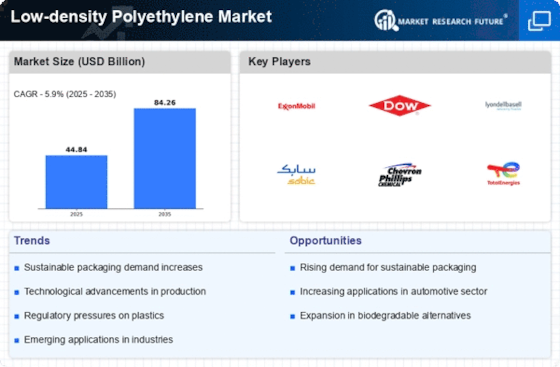

Key Companies in the Low-density Polyethylene market includes

-

Braskem

-

Chevron Phillips Chemical Company

-

INEOS

-

Mitsui Chemicals, Inc.

-

Formosa Plastics Corporation

-

Reliance Industries Limited

-

SABIC

-

Sasol

-

LyondellBasell Industries Holdings B.V.

-

China Petrochemical Corporation

-

Shell

-

Petkim Petrokimya Holding A.Ş

-

Qatar Petrochemical Company (QAPCO) Q.P.J.S.C.

-

Exxon Mobil Corporation

-

BASF SE among others

Recent Developments:

August 2023: Chevron Phillips Chemical announces a partnership with a major recycling company to develop closed-loop systems for Low-density Polyethylene waste.

September 2023: Borealis reports record profits driven by its focus on high-performance Low-density Polyethylene grades for the automotive industry.

December 2023: The global Low-density Polyethylene market shows signs of a slowdown due to economic uncertainty and geopolitical tensions.