Low Migration Inks Market Summary

As per Market Research Future analysis, the Low Migration Inks Market Size was estimated at 2.95 USD Billion in 2024. The Low Migration Inks industry is projected to grow from 3.171 USD Billion in 2025 to 6.531 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 7.49% during the forecast period 2025 - 2035

Key Market Trends & Highlights

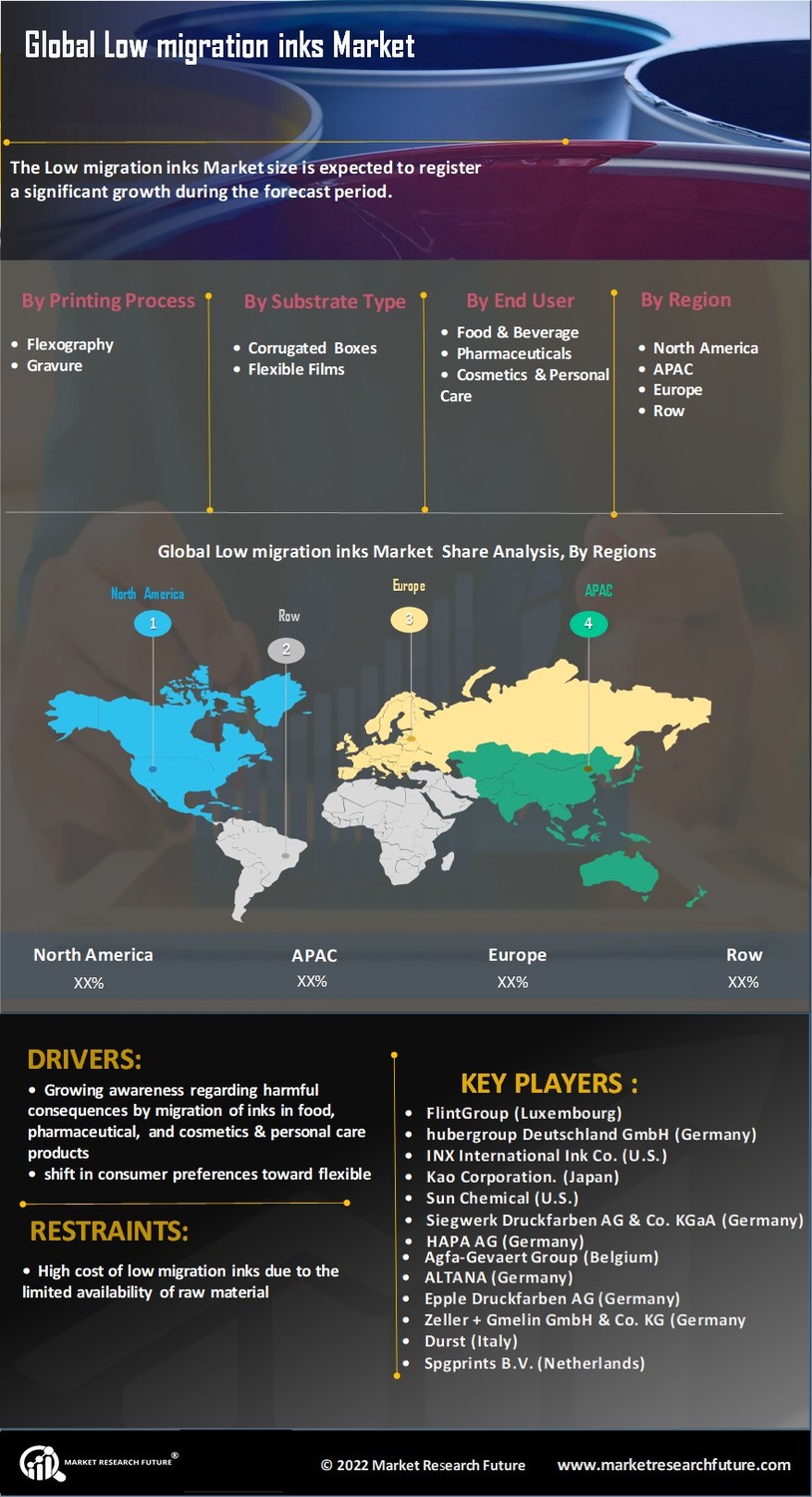

The Low Migration Inks Market is poised for growth driven by regulatory compliance and sustainability initiatives.

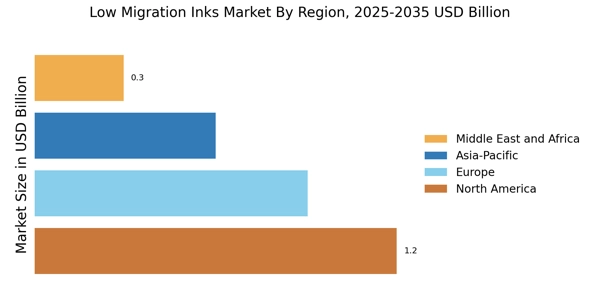

- North America remains the largest market for low migration inks, reflecting a strong demand in the packaging sector.

- Asia-Pacific is identified as the fastest-growing region, indicating a shift towards innovative printing solutions.

- Flexography continues to dominate as the largest segment, while gravure is emerging as the fastest-growing segment in the market.

- Consumer health awareness and regulatory pressures are key drivers propelling the adoption of low migration inks.

Market Size & Forecast

| 2024 Market Size | 2.95 (USD Billion) |

| 2035 Market Size | 6.531 (USD Billion) |

| CAGR (2025 - 2035) | 7.49% |

Major Players

Sun Chemical (US), Flint Group (LU), Siegwerk Druckfarben (DE), Huber Group (DE), Toyo Ink (JP), DIC Corporation (JP), INX International Ink Co. (US), Wikoff Color Corporation (US), Zeller+Gmelin (DE)