Growth in Industrial Applications

The Low-Temperature Industrial Boiler Market is witnessing growth driven by the expansion of industrial applications. Various sectors, including food processing, pharmaceuticals, and chemical manufacturing, are increasingly adopting low-temperature boilers for their specific heating needs. These industries require precise temperature control and efficient heating solutions, which low-temperature boilers can provide. The versatility of these boilers allows them to cater to diverse processes, making them an attractive option for manufacturers. Market data indicates that the food processing sector alone is projected to account for a significant share of the low-temperature boiler market, as companies seek to enhance production efficiency while maintaining product quality. This trend suggests a robust future for low-temperature industrial boilers across multiple sectors.

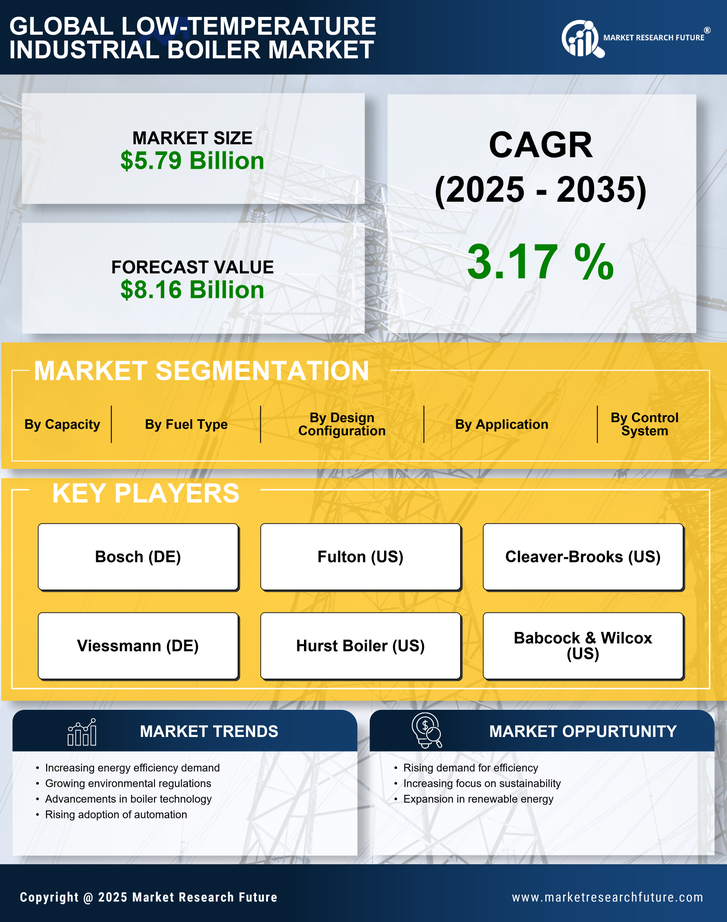

Rising Demand for Energy Efficiency

The Low-Temperature Industrial Boiler Market is experiencing a notable increase in demand for energy-efficient solutions. Industries are increasingly seeking to reduce operational costs and minimize energy consumption. This trend is driven by the need to comply with stringent energy regulations and to enhance sustainability practices. According to recent data, energy-efficient boilers can reduce energy consumption by up to 30%, which is a compelling incentive for industries to invest in low-temperature options. As companies strive to meet their sustainability goals, the adoption of low-temperature industrial boilers is likely to rise, further propelling market growth. The emphasis on energy efficiency not only aids in cost reduction but also aligns with global efforts to mitigate climate change, making this driver particularly relevant in the current market landscape.

Technological Innovations in Boiler Design

Technological advancements play a crucial role in shaping the Low-Temperature Industrial Boiler Market. Innovations in boiler design, such as improved heat exchangers and advanced control systems, enhance the efficiency and performance of low-temperature boilers. These innovations allow for better heat recovery and lower emissions, which are essential for industries aiming to meet environmental standards. The integration of smart technologies, such as IoT-enabled monitoring systems, further optimizes boiler operations, leading to increased reliability and reduced downtime. As industries adopt these cutting-edge technologies, the market for low-temperature industrial boilers is expected to expand significantly. The continuous evolution of boiler technology not only meets current demands but also anticipates future needs, ensuring that the industry remains competitive and responsive to changing market dynamics.

Increasing Focus on Environmental Regulations

The Low-Temperature Industrial Boiler Market is significantly influenced by the increasing focus on environmental regulations. Governments worldwide are implementing stricter emissions standards to combat air pollution and promote cleaner technologies. This regulatory landscape compels industries to transition from traditional high-temperature boilers to low-temperature alternatives that produce fewer emissions. For instance, regulations may require a reduction in nitrogen oxide and particulate matter emissions, which low-temperature boilers can effectively achieve. As a result, industries are likely to invest in low-temperature solutions to ensure compliance and avoid penalties. The alignment of market offerings with regulatory requirements not only enhances the appeal of low-temperature industrial boilers but also positions them as a viable solution for environmentally conscious businesses.

Cost-Effectiveness of Low-Temperature Solutions

Cost-effectiveness is a pivotal driver in the Low-Temperature Industrial Boiler Market. As industries face rising operational costs, the economic advantages of low-temperature boilers become increasingly appealing. These boilers typically require lower initial investments and offer reduced fuel consumption, leading to significant savings over time. Furthermore, the maintenance costs associated with low-temperature boilers are often lower compared to traditional high-temperature systems, making them a financially viable option for many businesses. Market analysis indicates that the total cost of ownership for low-temperature boilers can be substantially lower, which encourages industries to consider these solutions as a long-term investment. The combination of lower upfront costs and ongoing savings positions low-temperature industrial boilers as a strategic choice for companies aiming to optimize their financial performance.