Growing Applications in Defense

The defense sector is increasingly recognizing the advantages of magnesium beryllium alloys, which is positively impacting the Magnesium Beryllium Alloy Market. These alloys offer exceptional strength and lightweight characteristics, making them ideal for military applications such as armored vehicles and aircraft. As defense budgets expand and nations invest in advanced military technologies, the demand for high-performance materials is expected to rise. Recent reports indicate that defense spending is projected to increase by approximately 3% annually, which could lead to a corresponding growth in the use of magnesium beryllium alloys. This trend suggests a promising future for the Magnesium Beryllium Alloy Market as it aligns with the evolving needs of defense applications.

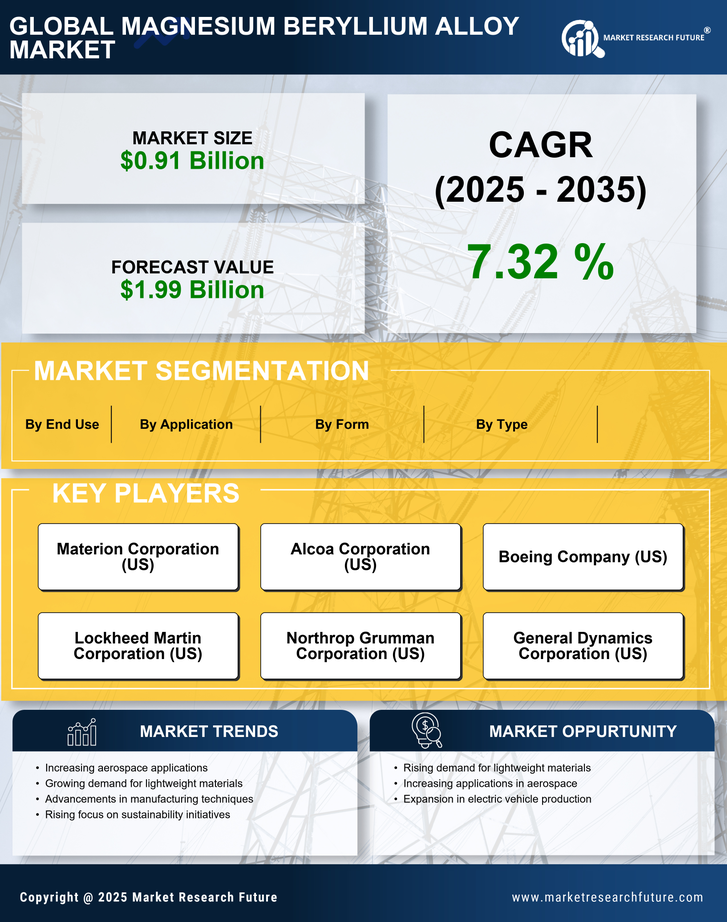

Rising Demand in Aerospace Sector

The Magnesium Beryllium Alloy Market is experiencing a notable surge in demand, particularly from the aerospace sector. This is largely attributed to the alloys' lightweight properties, which contribute to fuel efficiency and performance enhancement in aircraft. As airlines and manufacturers increasingly prioritize weight reduction to improve operational efficiency, the adoption of magnesium beryllium alloys is likely to rise. Recent data indicates that the aerospace industry is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years, further driving the need for advanced materials. Consequently, the Magnesium Beryllium Alloy Market stands to benefit significantly from this trend, as manufacturers seek to innovate and meet the evolving requirements of aerospace applications.

Advancements in Manufacturing Techniques

Innovations in manufacturing processes are playing a crucial role in shaping the Magnesium Beryllium Alloy Market. Techniques such as additive manufacturing and precision casting are enhancing the production efficiency and quality of these alloys. These advancements not only reduce waste but also allow for the creation of complex geometries that were previously unattainable. As manufacturers adopt these cutting-edge techniques, the cost of production may decrease, making magnesium beryllium alloys more accessible to various industries. Furthermore, the ability to produce high-performance components with improved mechanical properties is likely to attract new applications, thereby expanding the market reach of the Magnesium Beryllium Alloy Market.

Increased Focus on Lightweight Materials

The ongoing trend towards lightweight materials across various industries is significantly influencing the Magnesium Beryllium Alloy Market. As sectors such as automotive, aerospace, and electronics strive to enhance energy efficiency and reduce emissions, the demand for lightweight alloys is expected to grow. Magnesium beryllium alloys, known for their superior strength-to-weight ratio, are well-positioned to meet these needs. Market analysis suggests that the lightweight materials segment is anticipated to witness a growth rate of around 5% annually, further propelling the adoption of magnesium beryllium alloys. This shift towards lightweight solutions is likely to create new opportunities within the Magnesium Beryllium Alloy Market, as manufacturers seek to innovate and comply with stringent environmental regulations.

Environmental Regulations and Sustainability Initiatives

The Magnesium Beryllium Alloy Market is also being shaped by stringent environmental regulations and a growing emphasis on sustainability. As industries face increasing pressure to reduce their carbon footprints, the demand for eco-friendly materials is on the rise. Magnesium beryllium alloys, which can be recycled and have a lower environmental impact compared to traditional materials, are becoming more attractive to manufacturers. Regulatory frameworks aimed at promoting sustainable practices are likely to drive the adoption of these alloys across various sectors. Market forecasts indicate that the sustainability-focused materials segment could grow by 6% over the next few years, further enhancing the prospects for the Magnesium Beryllium Alloy Market.