Top Industry Leaders in the Manufacturing Sector ICT Market

Manufacturing Sector ICT Market: Dive into the Latest News and Updates

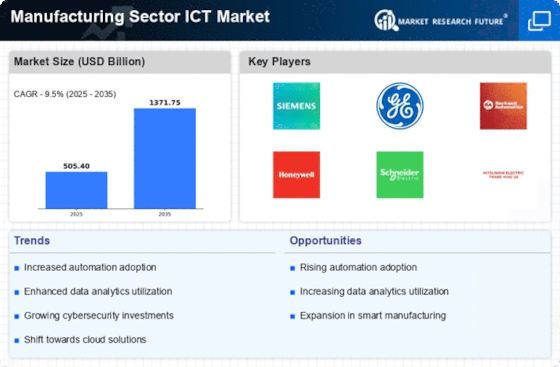

As the manufacturing landscape undergoes a digital transformation, Information and Communication Technologies (ICT) play an increasingly crucial role in optimizing operations, boosting efficiency, and driving growth.

Some of Manufacturing Sector ICT Companies Listed Below:

- Ericsson

- HP

- Cisco

- Samsung Electronics

- Intel

- NXP Semiconductors

- Microsoft

- Nokia

- Corning

- ASML

- SONY

- Hitachi

- Qualcomm

- Apple

- Dell

Strategies Driving Market Growth:

- Focus on Operational Efficiency and Cost Reduction: Implementing IIoT solutions, automation, and data analytics optimizes production processes, minimizes downtime, and reduces operational costs.

- Improved Quality and Traceability: Integrating advanced sensors and quality control systems with IT infrastructure ensures product quality, facilitates supply chain transparency, and enhances traceability.

- Predictive Maintenance and Asset Management: Utilizing data analytics and AI enables predictive maintenance, prevents equipment failures, and optimizes asset utilization.

- Enhanced Supply Chain Visibility and Collaboration: Implementing cloud-based solutions and integrated platforms creates a connected ecosystem, promoting real-time data sharing and collaboration across the supply chain.

Factors Influencing Market Share Analysis:

- Target Market and Industry Segment: Understanding the specific needs and challenges of different manufacturing verticals, such as automotive, aerospace, or consumer goods, is crucial for tailoring solutions and achieving market success.

- Technology Adoption and Integration: The ability to seamlessly integrate new ICT solutions with existing infrastructure and legacy systems directly impacts market acceptance and user adoption.

- Industry Standards and Cybersecurity: Adherence to industry standards and robust cybersecurity measures ensure data security, operational integrity, and compliance with regulations.

- Return on Investment (ROI) and Value Proposition: Quantifying the demonstrable ROI and clear value proposition of ICT solutions is essential for convincing manufacturers to invest.

New and Emerging Companies:

- Focus on Industry-Specific Solutions and AI-Powered Tools: Startups like Tupa Robotics, Brain Corp, Aiven provide solutions tailored to specific industries, utilize AI for predictive maintenance and process optimization, addressing niche needs and offering cutting-edge functionalities.

- Digital Twin Technology and Virtual Reality (VR) Training: Companies like Dassault Systèmes, PTC, Ansys offer digital twin platforms and VR training solutions, enabling efficient product design, simulation, and operator training.

- Focus on Sustainability and Green Manufacturing: Players like Siemens Xcelerator, EcoStruxure offer solutions for energy management, resource optimization, and carbon footprint reduction, addressing sustainability concerns and promoting eco-friendly production practices.

Current Investment Trends:

- Venture Capital Funding: Innovative startups developing niche solutions, AI-powered tools, and sustainability-focused technologies attract significant venture capital funding, fueling market diversification and innovation.

- Strategic Partnerships and Acquisitions: Established players are partnering with startups or acquiring niche expertise to expand their offerings and address emerging market needs.

- Investments in Industry 4.0 Technologies and Cloud Solutions: Growing investments in IIoT platforms, edge computing, and cloud-based solutions accelerate the adoption of Industry 4.0 technologies and pave the way for further digital transformation.

Latest Company Updates:

- Jan 29, 2024: Siemens launches its Xcelerator platform, offering a comprehensive suite of software and services for digital manufacturing, from product design to production and service.

- Jan 25, 2024: GE Digital unveils its Predix Industrial AI platform, featuring new capabilities for anomaly detection, predictive maintenance, and asset performance optimization.

- Jan 23, 2024:Microsoft announces the expansion of its Azure for Industry solutions, targeting specific needs of manufacturing sectors like automotive and discrete manufacturing.