Growing Aging Population

The growing aging population is a significant driver of the Medical Grade Plastic Market. As the global demographic shifts towards an older population, there is an increasing prevalence of chronic diseases and conditions that require medical intervention. This trend is leading to a higher demand for medical devices and equipment that utilize medical grade plastics. According to projections, the number of individuals aged 65 and older is expected to double by 2050, which will likely result in a surge in the need for healthcare services and medical devices. Consequently, manufacturers are focusing on developing innovative medical grade plastics that cater to the specific needs of this demographic, such as lightweight, durable, and biocompatible materials. This demographic shift is poised to create substantial opportunities for growth within the Medical Grade Plastic Market.

Increased Focus on Patient Safety

The heightened focus on patient safety is a crucial driver for the Medical Grade Plastic Market. Healthcare providers are increasingly prioritizing materials that minimize the risk of contamination and adverse reactions. Medical grade plastics are designed to meet rigorous safety standards, which is essential in applications such as drug delivery systems and surgical implants. The market is witnessing a shift towards materials that not only comply with regulatory standards but also enhance patient outcomes. Recent studies indicate that the use of high-quality medical grade plastics can reduce the incidence of infections and complications associated with medical devices. This emphasis on safety is likely to drive demand for medical grade plastics, as healthcare facilities seek to improve patient care and reduce liability risks associated with inferior materials.

Rising Demand for Medical Devices

The increasing demand for medical devices is a primary driver of the Medical Grade Plastic Market. As healthcare systems evolve, there is a notable rise in the production of devices such as syringes, catheters, and surgical instruments, which require high-quality medical grade plastics. According to recent data, the medical device market is projected to reach approximately 500 billion USD by 2026, indicating a robust growth trajectory. This surge in demand necessitates the use of materials that meet stringent safety and performance standards, thereby propelling the Medical Grade Plastic Market forward. Manufacturers are increasingly focusing on sourcing materials that not only comply with regulatory requirements but also enhance the functionality and durability of medical devices. Consequently, this trend is likely to foster innovation and investment in the medical grade plastics sector.

Advancements in Polymer Technology

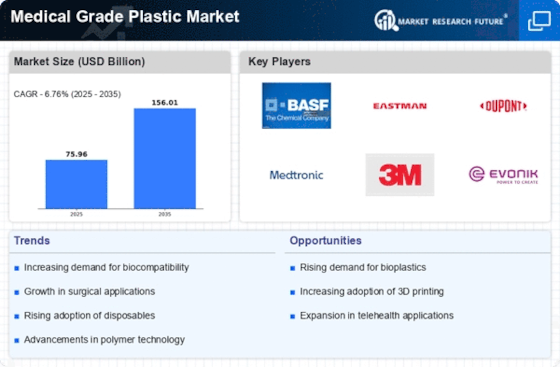

Advancements in polymer technology are significantly influencing the Medical Grade Plastic Market. Innovations in material science have led to the development of new polymers that exhibit enhanced biocompatibility, mechanical strength, and sterilization capabilities. For instance, the introduction of polyether ether ketone (PEEK) and polycarbonate materials has expanded the applications of medical grade plastics in implants and prosthetics. The market for these advanced materials is expected to grow, with estimates suggesting a compound annual growth rate of around 7% over the next few years. This growth is driven by the need for materials that can withstand harsh sterilization processes while maintaining their integrity and performance. As a result, manufacturers are increasingly investing in research and development to create next-generation medical grade plastics that meet the evolving needs of the healthcare industry.

Regulatory Standards and Compliance

Regulatory standards and compliance play a pivotal role in shaping the Medical Grade Plastic Market. Stringent regulations imposed by health authorities ensure that medical grade plastics meet specific safety and efficacy criteria. Compliance with these regulations is not only essential for market entry but also for maintaining consumer trust. The medical plastics market is subject to various international standards, including ISO 13485 and FDA regulations, which govern the manufacturing processes and material properties. As the industry evolves, manufacturers are increasingly investing in quality assurance and regulatory compliance to ensure their products meet these standards. This focus on compliance is likely to drive innovation in the Medical Grade Plastic Market, as companies strive to develop materials that not only meet regulatory requirements but also offer superior performance and safety.