Rising Demand for Durable Products

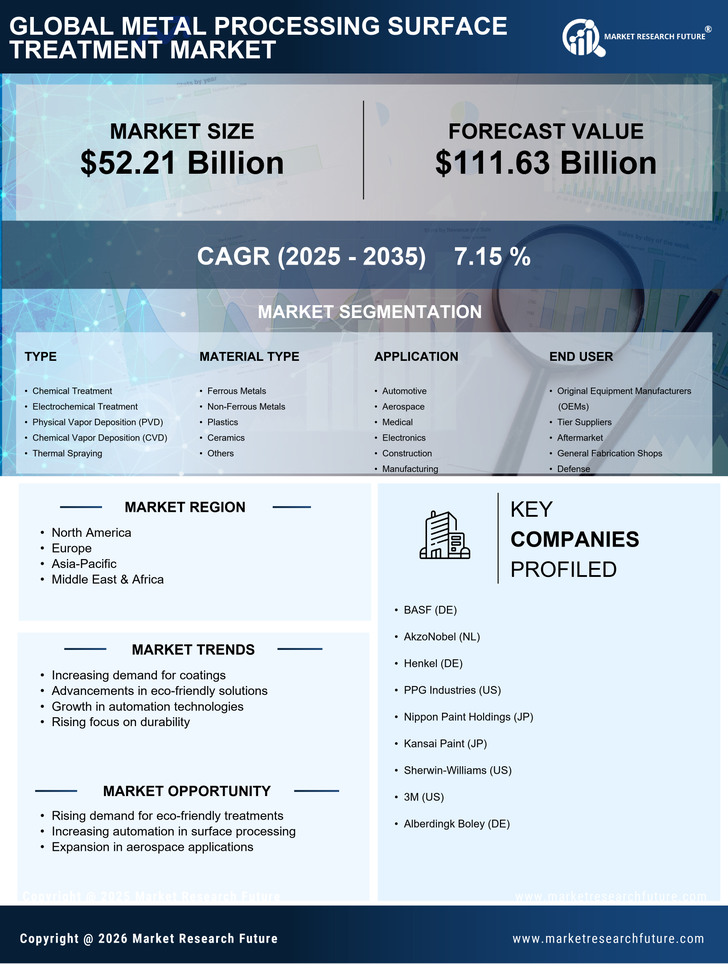

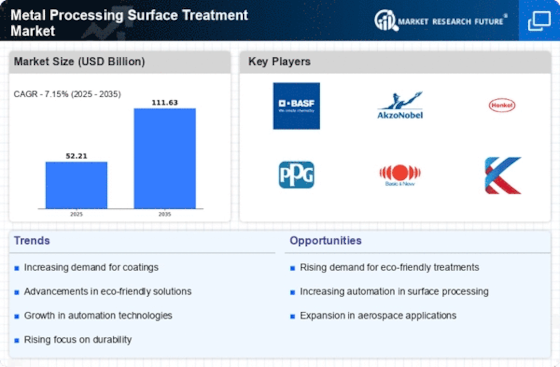

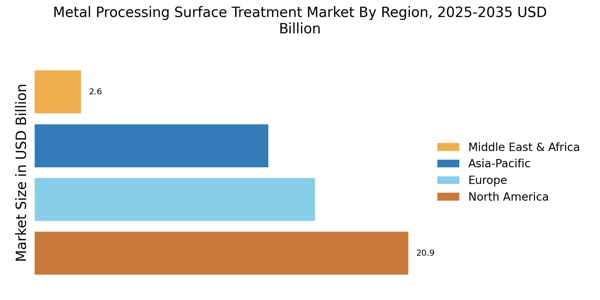

The Metal Processing Surface Treatment Market is experiencing a notable increase in demand for durable and long-lasting products. Industries such as automotive, aerospace, and construction are increasingly prioritizing materials that can withstand harsh conditions. This trend is driven by the need for enhanced performance and longevity of components, which is critical in reducing maintenance costs and improving overall efficiency. As a result, surface treatment processes that enhance corrosion resistance, wear resistance, and aesthetic appeal are gaining traction. The market for surface treatment is projected to grow at a compound annual growth rate of approximately 5% over the next few years, indicating a robust demand for treated metals that meet these durability standards.

Increased Focus on Aesthetic Appeal

The Metal Processing Surface Treatment Market is witnessing a growing emphasis on the aesthetic appeal of metal products. As consumer preferences evolve, industries such as consumer electronics, furniture, and decorative applications are increasingly seeking surface treatments that enhance visual characteristics. This trend is driving the demand for finishes that provide not only functional benefits but also aesthetic enhancements, such as color, texture, and gloss. Manufacturers are responding by developing innovative surface treatment solutions that cater to these aesthetic requirements. The market is likely to see a rise in the adoption of decorative coatings and finishes, contributing to an overall increase in market value as companies strive to meet consumer expectations for visually appealing products.

Environmental Regulations and Compliance

The Metal Processing Surface Treatment Market is significantly influenced by stringent environmental regulations aimed at reducing pollution and promoting sustainable practices. Governments across various regions are implementing regulations that mandate the use of eco-friendly surface treatment processes. This has led to an increased adoption of water-based coatings and other environmentally friendly alternatives. Companies are investing in research and development to comply with these regulations while maintaining product quality. The market is expected to see a shift towards greener technologies, with a projected increase in the use of non-toxic materials and processes that minimize environmental impact. This shift not only aligns with regulatory requirements but also caters to the growing consumer preference for sustainable products.

Growth of the Automotive and Aerospace Sectors

The Metal Processing Surface Treatment Market is closely linked to the growth trajectories of the automotive and aerospace sectors. As these industries expand, the demand for high-performance materials that require effective surface treatments is on the rise. The automotive sector, in particular, is focusing on lightweight materials to improve fuel efficiency, which necessitates advanced surface treatments to enhance strength and durability. Similarly, the aerospace industry requires components that can withstand extreme conditions, leading to increased investments in surface treatment technologies. The combined growth of these sectors is expected to propel the surface treatment market, with projections indicating a potential increase in market size by over 20% in the next five years.

Technological Innovations in Surface Treatment

Technological advancements are playing a pivotal role in shaping the Metal Processing Surface Treatment Market. Innovations such as advanced coating techniques, laser surface treatment, and nanotechnology are enhancing the efficiency and effectiveness of surface treatments. These technologies enable manufacturers to achieve superior surface properties, such as improved adhesion, enhanced hardness, and better corrosion resistance. The integration of automation and robotics in surface treatment processes is also streamlining operations, reducing labor costs, and increasing production rates. As industries continue to seek competitive advantages through improved product performance, the adoption of these cutting-edge technologies is likely to accelerate, further driving market growth.