- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

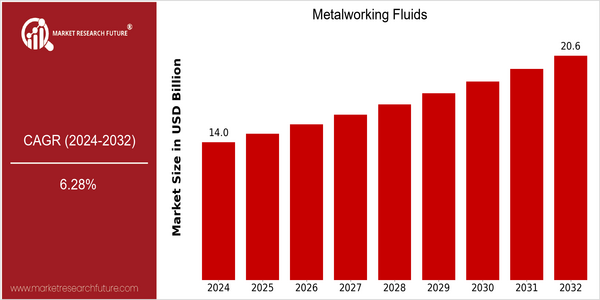

| Year | Value |

|---|---|

| 2024 | USD 14.01 Billion |

| 2032 | USD 20.62 Billion |

| CAGR (2024-2032) | 6.28 % |

Note – Market size depicts the revenue generated over the financial year

The global metalworking fluids market is poised for significant growth, with a current market size of USD 14.01 billion in 2024, projected to reach USD 20.62 billion by 2032. This growth trajectory reflects a compound annual growth rate (CAGR) of 6.28% over the forecast period. The increasing demand for precision machining and the rising adoption of advanced manufacturing technologies are key drivers of this market expansion. As industries strive for enhanced efficiency and productivity, the need for high-performance metalworking fluids that can withstand extreme conditions and improve tool life is becoming increasingly critical. Technological advancements, such as the development of bio-based and environmentally friendly metalworking fluids, are also contributing to market growth. These innovations not only address environmental concerns but also meet the evolving regulatory standards across various regions. Key players in the market, including companies like ExxonMobil, Chevron, and Fuchs Petrolub, are actively investing in research and development to introduce new formulations and expand their product portfolios. Strategic initiatives, such as partnerships and collaborations aimed at enhancing distribution networks and customer reach, further underscore the competitive landscape of the metalworking fluids market.

Regional Market Size

Regional Deep Dive

The Metalworking Fluids Market is characterized by diverse dynamics across different regions, influenced by industrial growth, technological advancements, and regulatory frameworks. In North America, the market is driven by a robust manufacturing sector and increasing demand for high-performance fluids. Europe showcases a strong emphasis on sustainability and eco-friendly products, while Asia-Pacific is experiencing rapid industrialization and a growing automotive sector, leading to heightened demand for metalworking fluids. The Middle East and Africa are witnessing gradual growth, supported by infrastructural developments, whereas Latin America is focusing on modernization and efficiency in manufacturing processes.

Europe

- The European Union's REACH regulation is pushing companies to reformulate their metalworking fluids to comply with safety and environmental standards, leading to a surge in demand for bio-based fluids.

- Companies such as Fuchs Petrolub SE are leading the way in developing sustainable metalworking fluids, which are gaining traction among manufacturers focused on reducing their carbon footprint.

Asia Pacific

- China's rapid industrial growth has led to increased investments in the metalworking sector, with local companies like Sinopec developing tailored metalworking fluids to meet specific industry needs.

- The rise of electric vehicles in countries like Japan and South Korea is driving demand for specialized metalworking fluids that cater to the unique requirements of EV manufacturing.

Latin America

- Brazil's government has launched programs to modernize its manufacturing sector, which is expected to boost the demand for advanced metalworking fluids.

- Local companies are increasingly adopting sustainable practices, with firms like Petronas developing eco-friendly metalworking fluids to cater to the growing environmental awareness among manufacturers.

North America

- The U.S. Environmental Protection Agency (EPA) has introduced stricter regulations on the disposal of metalworking fluids, prompting manufacturers to innovate and develop more environmentally friendly products.

- Key players like ExxonMobil and Chevron are investing in R&D to create advanced synthetic metalworking fluids that enhance performance and reduce environmental impact.

Middle East And Africa

- The UAE's Vision 2021 initiative is fostering growth in the manufacturing sector, leading to increased demand for high-quality metalworking fluids to support local industries.

- Companies like TotalEnergies are expanding their operations in the region, focusing on providing innovative metalworking fluid solutions to meet the needs of emerging markets.

Did You Know?

“Approximately 30% of metalworking fluids are disposed of improperly, leading to significant environmental concerns and prompting regulatory bodies to enforce stricter disposal guidelines.” — U.S. Environmental Protection Agency (EPA)

Segmental Market Size

The Metalworking Fluids segment plays a crucial role in the manufacturing sector, particularly in machining and metal fabrication processes. This segment is currently experiencing stable growth, driven by increasing demand for precision engineering and advancements in manufacturing technologies. Key factors propelling this demand include the need for enhanced tool life and performance, as well as stringent regulatory policies aimed at reducing environmental impact and improving worker safety. Currently, the adoption of advanced metalworking fluids is in the mature stage, with companies like ExxonMobil and Castrol leading the way in innovation and sustainability practices. Primary applications include machining operations in automotive, aerospace, and general manufacturing industries, where these fluids are essential for cooling, lubrication, and chip removal. Trends such as the push for sustainable manufacturing practices and the integration of Industry 4.0 technologies are accelerating growth in this segment. Additionally, the development of bio-based and environmentally friendly metalworking fluids is reshaping the market landscape, aligning with global sustainability initiatives.

Future Outlook

The Metalworking Fluids market is poised for significant growth from 2024 to 2032, with a projected market value increase from $14.01 billion to $20.62 billion, reflecting a robust compound annual growth rate (CAGR) of 6.28%. This growth trajectory is underpinned by the rising demand for advanced manufacturing processes across various industries, including automotive, aerospace, and metal fabrication. As manufacturers increasingly adopt automation and precision engineering, the need for high-performance metalworking fluids that enhance efficiency and extend tool life will become paramount. By 2032, it is anticipated that the penetration of synthetic and bio-based metalworking fluids will rise, driven by their superior performance characteristics and growing environmental regulations favoring sustainable solutions. Key technological advancements, such as the development of smart metalworking fluids that incorporate nanotechnology and additives for improved cooling and lubrication, are expected to further propel market growth. Additionally, stringent regulations regarding worker safety and environmental impact will drive the adoption of eco-friendly formulations. Emerging trends, including the integration of Industry 4.0 practices, will also influence the market, as manufacturers seek to optimize fluid management systems through data analytics and IoT solutions. Overall, the Metalworking Fluids market is set to evolve significantly, with a focus on innovation and sustainability shaping its future landscape.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 12.21 Billion |

| Market Size Value In 2023 | USD 13.16 Billion |

| Growth Rate | 6.28% (2023-2030) |

Metalworking Fluids Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.