Rising Demand in Construction Industry

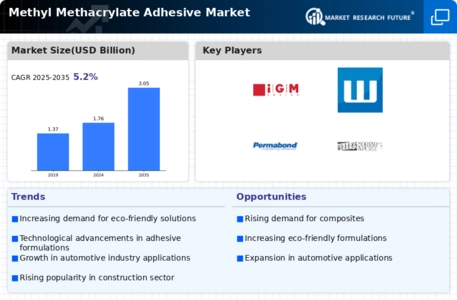

The Methyl Methacrylate Adhesive Market is experiencing a notable surge in demand driven by the construction sector. As urbanization accelerates, the need for durable and efficient bonding solutions in construction applications becomes paramount. Methyl methacrylate adhesives are favored for their exceptional bonding strength and resistance to environmental factors, making them ideal for structural applications. According to recent data, the construction industry is projected to grow at a compound annual growth rate of approximately 5% over the next few years, further propelling the demand for these adhesives. This growth is likely to be fueled by ongoing infrastructure projects and the increasing use of prefabricated materials, which require reliable adhesive solutions. Consequently, the Methyl Methacrylate Adhesive Market is poised to benefit significantly from this trend.

Emphasis on Sustainable Manufacturing Practices

The Methyl Methacrylate Adhesive Market is increasingly shaped by the emphasis on sustainable manufacturing practices. As industries strive to reduce their environmental footprint, the demand for eco-friendly adhesive solutions is on the rise. Methyl methacrylate adhesives are being formulated to meet stringent environmental regulations, which enhances their appeal in various applications. The market for sustainable adhesives is expected to grow at a compound annual growth rate of around 7%, reflecting a shift towards greener alternatives. This trend is likely to drive innovation within the Methyl Methacrylate Adhesive Market, as manufacturers develop products that not only perform well but also align with sustainability goals. Consequently, the focus on eco-friendly solutions may provide a competitive edge for companies operating in this market.

Increasing Adoption in Automotive Manufacturing

The Methyl Methacrylate Adhesive Market is significantly influenced by the automotive manufacturing sector, which is increasingly adopting advanced adhesive technologies. Methyl methacrylate adhesives are preferred for their ability to bond dissimilar materials, such as metals and plastics, which is crucial in modern vehicle design. The automotive industry is projected to grow at a rate of approximately 4% per year, driven by the demand for lightweight vehicles that enhance fuel efficiency. As automakers focus on reducing vehicle weight while maintaining structural integrity, the use of methyl methacrylate adhesives is likely to expand. This trend indicates a promising outlook for the Methyl Methacrylate Adhesive Market, as it aligns with the industry's shift towards innovative bonding solutions.

Growth in Electronics and Electrical Applications

The Methyl Methacrylate Adhesive Market is witnessing substantial growth due to the increasing utilization of adhesives in electronics and electrical applications. These adhesives are essential for bonding components in devices such as smartphones, computers, and other electronic gadgets. The electronics sector is expected to expand at a rate of around 6% annually, driven by technological advancements and rising consumer demand for innovative products. Methyl methacrylate adhesives are particularly valued for their excellent thermal stability and electrical insulation properties, making them suitable for various electronic applications. As manufacturers seek to enhance product performance and reliability, the demand for high-quality adhesives is likely to rise, thereby benefiting the Methyl Methacrylate Adhesive Market.

Technological Innovations in Adhesive Formulations

The Methyl Methacrylate Adhesive Market is benefiting from ongoing technological innovations in adhesive formulations. Advances in polymer chemistry and manufacturing processes are leading to the development of high-performance adhesives that offer superior bonding capabilities. These innovations are crucial as industries seek to enhance product durability and performance. The market for advanced adhesive technologies is projected to grow at a rate of approximately 5% annually, driven by the need for specialized solutions in various sectors. Methyl methacrylate adhesives, with their rapid curing times and excellent adhesion properties, are becoming increasingly popular in applications ranging from construction to automotive. This trend suggests a robust future for the Methyl Methacrylate Adhesive Market as it adapts to the evolving needs of diverse industries.