Motor Lamination Market Overview

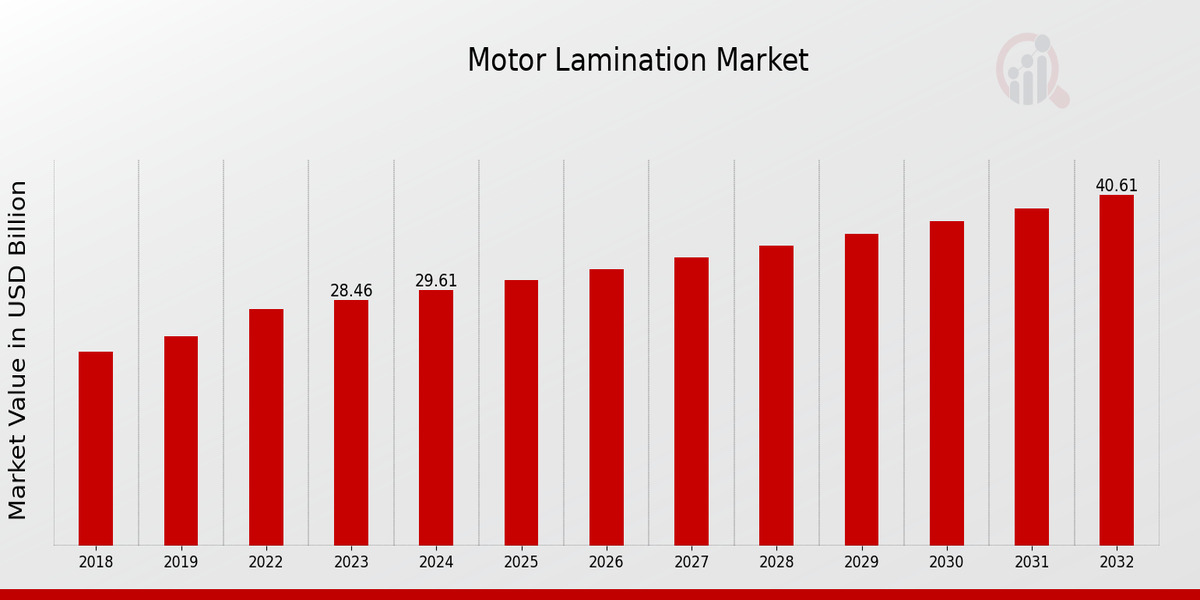

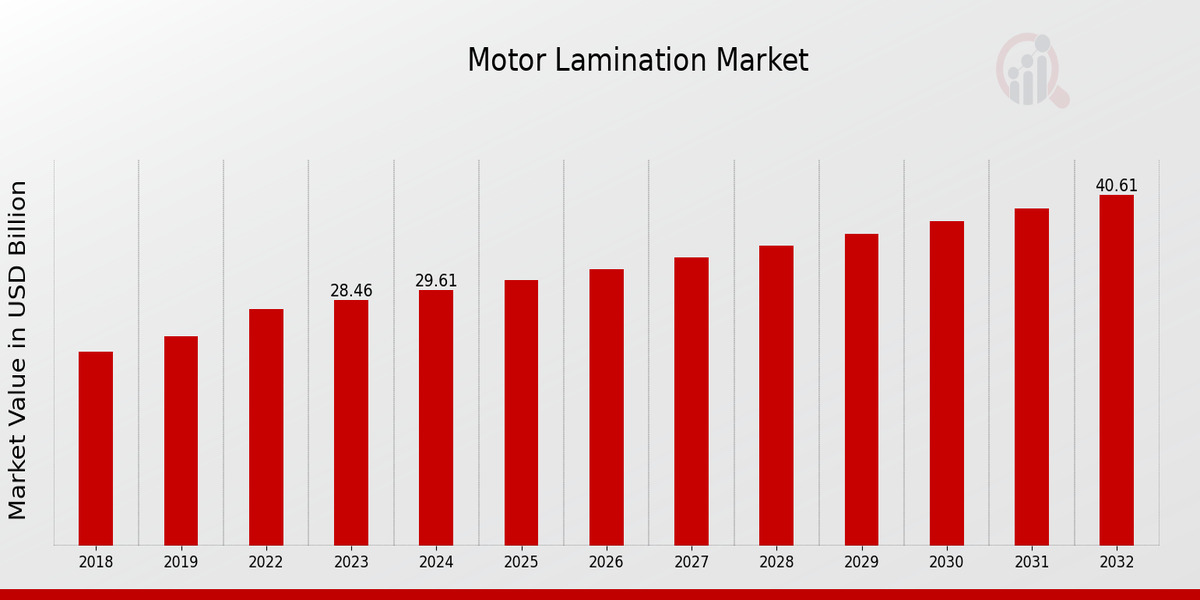

As per MRFR analysis, the Motor Lamination Market Size was estimated at 30.80 (USD Billion) in 2024. The Motor Lamination Market Industry is expected to grow from 32.05 (USD Billion) in 2025 to 45.74 (USD Billion) till 2034, at a CAGR (growth rate) is expected to be around 4.32% during the forecast period (2025 - 2034).

Key Motor Lamination Market Trends Highlighted

The Motor Lamination Market is experiencing significant growth due to various key market drivers, such as the rising demand for electric vehicles fueled by the shift towards sustainable transportation. The increasing focus on energy efficiency and the need to reduce emissions significantly contribute to the demand for high-performance motor laminations. Technological advancements in manufacturing processes, such as improved lamination techniques and materials, enable the production of more efficient electric motors, further boosting market growth. Additionally, opportunities to be explored include expanding applications across various sectors, such as automotive, industrial machinery, and renewable energy sectors.

The advent of electric and hybrid vehicles presents considerable potential for the motor lamination market. Companies can also capture market opportunities by investing in research and development to innovate new products that cater to the evolving needs of consumers. In recent times, there has been a noticeable trend towards the use of lightweight materials and enhanced design features that improve overall motor efficiency. The integration of smart technologies in electric motors and the growing interest in automation and robotics are also reshaping the landscape of the motor lamination market.

Sustainability has become a key focus, with manufacturers increasingly seeking environmentally friendly materials and processes.The combination of these trends suggests a dynamic market environment that is ripe for innovation and growth. Companies that adapt to these changes and focus on sustainability and efficiency are likely to thrive in the competitive landscape of the Motor Lamination Market.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Motor Lamination Market Drivers

Growing Demand for Efficient Electric Motors

The Motor Lamination Industry is witnessing an increasing demand for efficient electric motors across various sectors, including automotive, aerospace and industrial machinery. This demand stems from the need for energy-efficient solutions as organizations and consumers alike prioritize sustainability and cost-saving measures. The push towards electric mobility, primarily through electric vehicles (EVs), has significantly influenced the market as manufacturers seek lightweight, high-performance motors that utilize advanced lamination designs.Enhancements in motor design, facilitated by advanced materials and manufacturing technologies, have led to a reduction in losses, improved thermal management, and minimized noise levels.

As these electric motors are integral to the movement towards electrification, the focus on production methodologies that enhance motor performance challenges stakeholders in the Motor Lamination Industry to innovate and adapt. Additionally, governments worldwide are imposing stricter energy efficiency regulations, further encouraging manufacturers to upgrade their motor lamination processes.As industries transition towards greener alternatives, the demand for electric motors is anticipated to grow substantially, driving advancements in motor lamination technology to sustain this growth trajectory.

Rising Adoption of Renewable Energy Sources

The Motor Lamination Industry is significantly influenced by the rising adoption of renewable energy sources, especially wind and solar power. These sectors utilize advanced electric motors for efficient energy conversion and generation, necessitating the use of high-quality motor laminations. Wind turbines, for example, rely heavily on sophisticated electric motors to convert wind energy into electricity, requiring laminations that enhance performance and durability.The growth in renewable energy initiatives fosters further investment in research and development, aiming to improve motor technology and lamination designs.

Technological Advancements in Manufacturing Processes

Technological advancements in manufacturing processes have become a key driver for the Motor Lamination Industry. Innovations such as additive manufacturing, precision machining, and automation are enhancing production efficiency and reducing costs. These advancements enable manufacturers to create complex lamination designs that optimize motor performance. Moreover, improvements in material science have led to the development of high-performance magnetic materials, which are essential for efficient motor operation, further propelling the growth of the market.

Motor Lamination Market Segment Insights:

Motor Lamination Market Application Insights

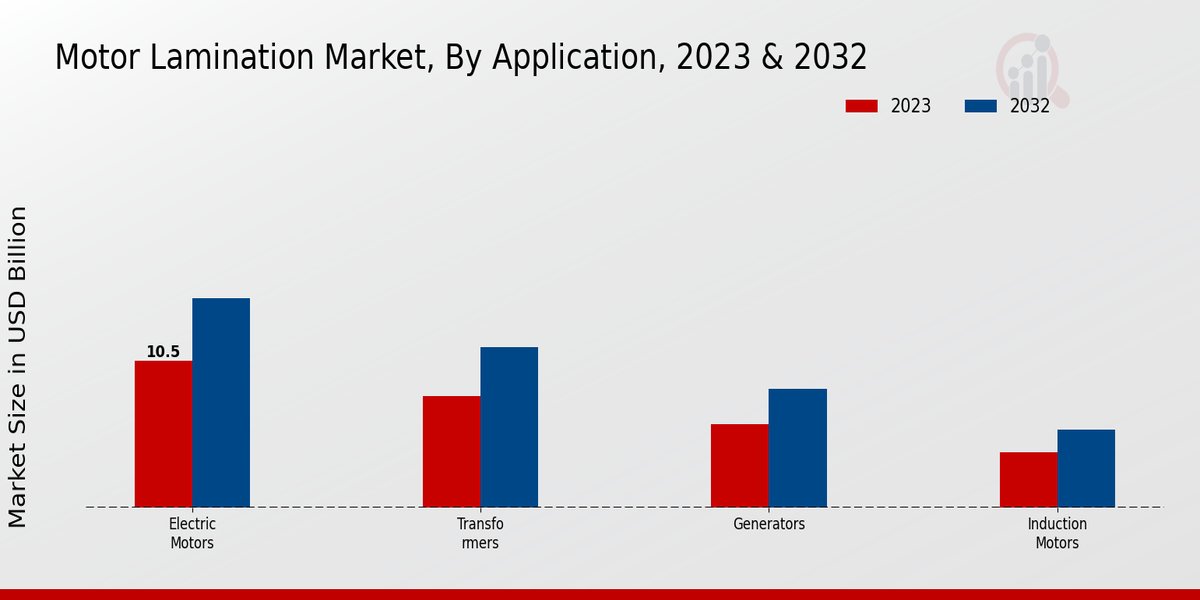

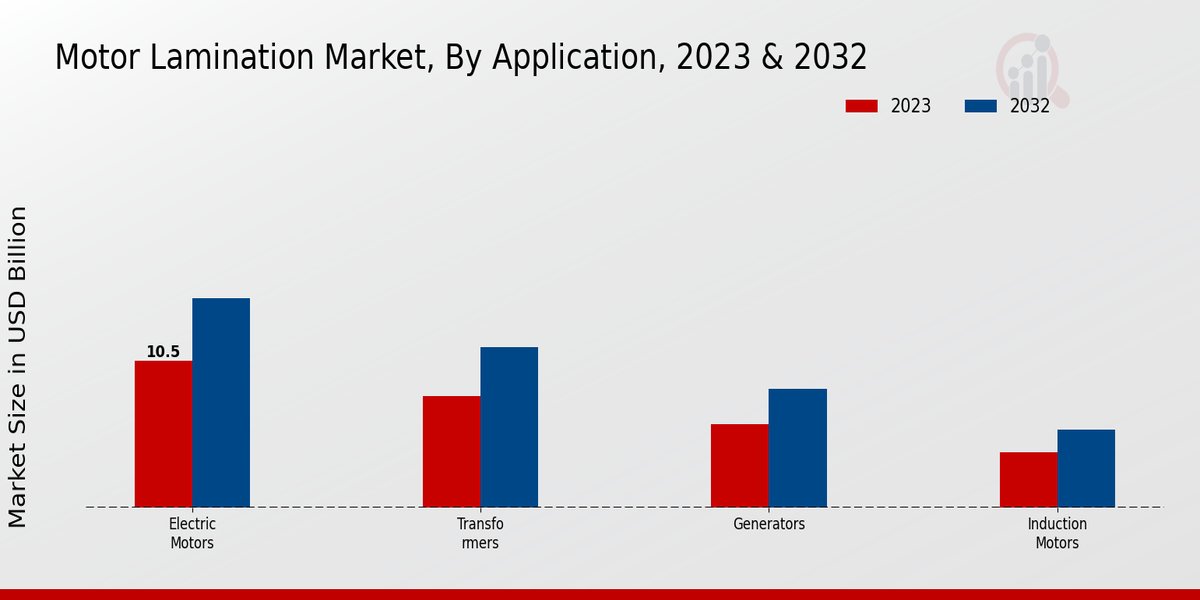

The Motor Lamination Market reflects a strong growth trajectory, with the Application segment playing a crucial role within this landscape. Electric Motors dominates this segment, with a valuation of 10.5 USD Billion in 2023 and projected to rise to 15.0 USD Billion in 2032, illustrating a significant share in the overall market.

The substantial demand for electric vehicles and automation drives this segment's growth, highlighting the essential role of electric motors in energy efficiency and innovation. Following closely is the Transformers category, valued at 8.0 USD Billion in 2023 and expected to reach 11.5 USD Billion by 2032, which underscores their critical importance in voltage regulation and electrical distribution, fundamental for modern infrastructure and renewable energy integration.This segment's growth is stimulated by rising investments in smart grid technologies and an increasing focus on renewable energy sources, solidifying transformers as a key component in the energy transition.

The Generators segment, with a valuation of 6.0 USD Billion in 2023 set to expand to 8.5 USD Billion by 2032, showcases its vital role in providing backup power solutions and renewable energy generation systems.

This growth is mainly attributed to the increasing need for reliable energy sources in various sectors, including residential, commercial, and industrial applications.Lastly, the Induction Motors segment, valued at 3.96 USD Billion in 2023, moving to 5.6 USD Billion in 2032, represents the smallest share but remains significant due to their application in industrial drives and HVAC systems. The steady rise in this segment is supported by the growing emphasis on energy-efficient solutions in manufacturing and building facilities, making induction motors a mainstay in operational efficiency.

Overall, the Motor Lamination Market statistics reveal profound insights into the Application segment's sub-categories, showcasing a balance of demand-driven growth across different applications.Each segment reflects a blend of market growth factors, customer demand dynamics, and technological advancements, all contributing to shaping the future landscape of the industry.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Motor Lamination Market Material Type Insights

Silicon Steel dominates the market due to its excellent magnetic properties, making it highly efficient for electrical applications, particularly in motors and transformers. Non-Silicon Steel offers a cost-effective alternative and is primarily used in applications where high efficiency is less critical. Amorphous Steel, while holding a minor share, is gaining traction due to its energy efficiency and low core loss characteristics, presenting opportunities for innovation in advanced applications.

The steady demand for efficient electric motors, driven by the rise in renewable energy projects and electric vehicles, contributes to the growth of these material types within the Motor Lamination industry. However, challenges such as fluctuating raw material prices and the need for advanced manufacturing techniques can impact the segment. With these dynamics, the segmented market continues to evolve, presenting a vibrant landscape for stakeholders aiming to leverage the opportunities within the Motor Lamination Market.

Motor Lamination Market Process Insights

This market segment involves critical operations like Stamping, Lamination and Coating, which are essential for producing efficient and high-performance motor laminations. Stamping plays a key role in shaping the core components of electric motors, thus significantly contributing to the overall efficiency of the motor systems. Lamination acts as a crucial process that minimizes energy losses, making it an essential factor for optimization in electric motor applications.

On the other hand, Coating serves as a protective layer that enhances the durability of the laminations, ensuring longevity in various operational environments. The growth of the Motor Lamination Market revenue is spurred by increasing demand for electric vehicles and energy-efficient appliances. However, the market also faces challenges, such as the rising costs of raw materials and stringent regulations in manufacturing processes. Overall, the Motor Lamination Market data indicates a steady growth trajectory, driven by advancements in technology and rising consumer preferences for energy efficiency.

Motor Lamination Market End Use Industry Insights

The Automotive sector plays a pivotal role, driven by the growing demand for electric vehicles and energy-efficient motors, which require advanced lamination technologies. The Aerospace industry, on the other hand, benefits from stringent lightweight and efficiency requirements, leading to a higher demand for premium lamination materials in aircraft designs. Industrial Machinery also represents a major share, propelled by the automation trend across manufacturing processes, necessitating optimized motor solutions.

Home Appliances, with an increasing focus on smart technologies and energy efficiency, further emphasizes the importance of effective motor laminations. This diverse market segmentation highlights the overall growth of the Motor Lamination Market, as each of these industries contributes significantly to overall market dynamics. The market growth is supported by robust innovations and advancements in materials and manufacturing, paving the way for future opportunities. As the industry continues to evolve, the demand for efficient and reliable motor lamination solutions across varying applications will remain a key driver for market expansion.

Motor Lamination Market Regional Insights

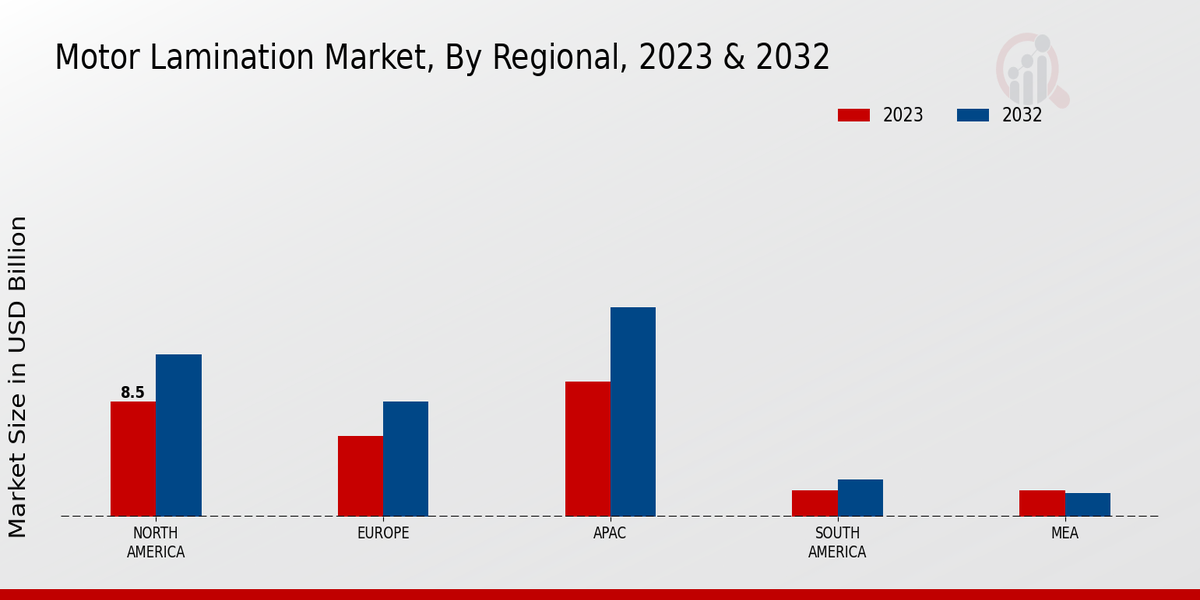

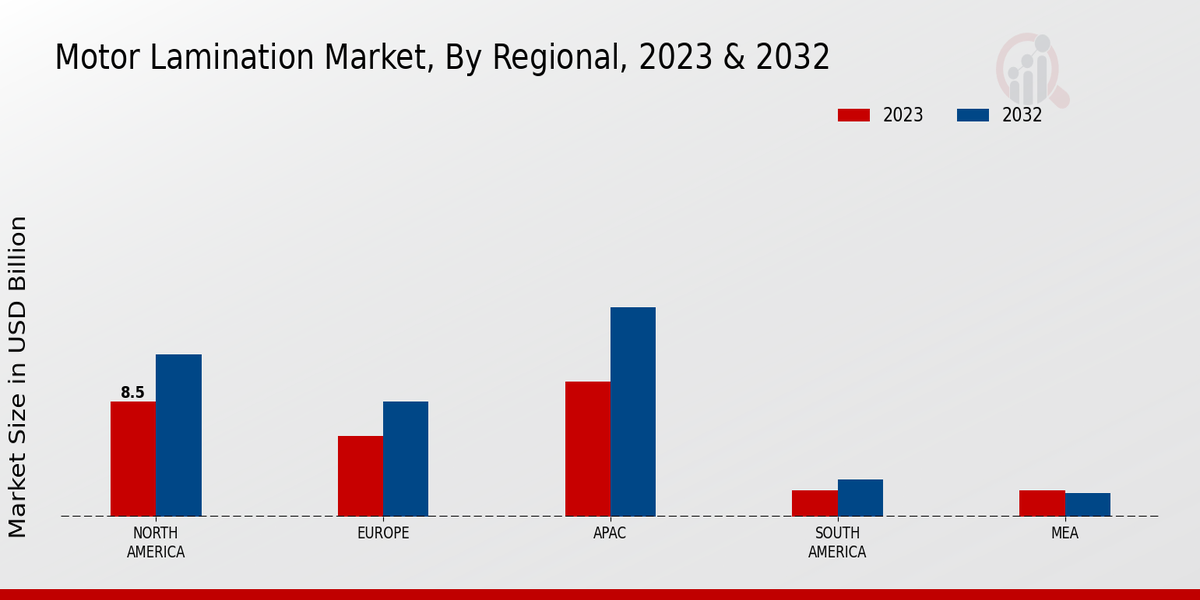

The Motor Lamination Market is witnessing significant growth across various regions, showing diverse valuations that highlight regional dynamics. In 2023, North America was valued at 8.5 USD Billion, making it a substantial player and reflecting the region's advanced manufacturing capabilities and technological adoption. Europe follows with a valuation of 6.0 USD Billion, benefiting from a strong automotive industry and stringent energy efficiency regulations.

The APAC region dominates the market at 10.0 USD Billion, driven by rapid industrialization, increased electric vehicle production, and a growing consumer base, which is crucial for the Motor Lamination Market revenue growth.South America, at 2.0 USD Billion, indicates a developing market with potential, while the MEA region, valued at 1.96 USD Billion, is the least dominant yet presents emerging opportunities due to increasing investments in infrastructure and renewable energy projects.

The varied market growth across these regions is shaped by local economic conditions, technological advancements, and shifts towards sustainable energy solutions, presenting distinct challenges and opportunities for stakeholders in the Motor Lamination industry.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Motor Lamination Market Key Players and Competitive Insights:

The Motor Lamination Market is characterized by a diverse range of players striving to gain a competitive edge in a landscape that is rapidly evolving due to technological advancements and changing consumer demands. The market comprises manufacturers specializing in motor laminations, which are essential components used in electric motors to enhance their efficiency, magnetic properties, and performance. Competition in this sector is informed by factors such as innovation in materials and designs, cost-effectiveness, and the ability to respond to the growing trends of electric vehicles and renewable energy sources.

As companies invest in research and development to improve their products and differentiate themselves, collaboration with automotive and industrial sectors is also becoming a significant strategy for companies looking to extend their market reach.Littelfuse holds a significant presence in the Motor Lamination Market by leveraging its advanced engineering capabilities and innovative solutions. The company has been recognized for its high-quality lamination products that cater to a variety of motor applications, which bolster both performance and durability. Littelfuse's commitment to sustainability and energy efficiency resonates well with the growing demand for eco-friendly products in the market.

Furthermore, the company's extensive portfolio allows it to meet an array of customer needs, positioning it strongly against competitors. With its focus on leveraging cutting-edge technology, Littelfuse is adept at providing custom solutions that fit specific requirements, further enhancing its competitive standing in the motor lamination space.Parker Hannifin stands as a formidable player in the Motor Lamination Market, distinguished by its comprehensive range of solutions that address the intricate demands of motor design and manufacturing. The company's robust engineering expertise enables it to create advanced lamination products that contribute to reduced weight and increased efficiency in electric motors.

Parker Hannifin places a strong emphasis on innovation, consistently enhancing its product offerings to align with the latest technological developments and industry trends.

Additionally, its extensive distribution network and partnerships allow for seamless market penetration and customer service. The focus on reliability and performance has made Parker Hannifin a trusted name among manufacturers looking for high-performing lamination solutions, thereby affirming its role as a key competitor in the market.

Key Companies in the Motor Lamination Market Include:

Motor Lamination Industry Developments

-

Q2 2024: EuroGroup Laminations inaugurates new manufacturing facility in Mexico to meet growing demand for EV motor laminations EuroGroup Laminations S.p.A. announced the opening of a new production facility in Mexico, aimed at expanding its capacity to supply motor laminations for electric vehicles in North America. The facility is expected to enhance the company's ability to serve major automotive OEMs in the region.

-

Q1 2024: POSCO launches new high-efficiency non-oriented electrical steel for EV motor laminations POSCO introduced a new grade of non-oriented electrical steel designed specifically for use in electric vehicle motor laminations, targeting improved efficiency and reduced energy loss in next-generation EV motors.

-

Q2 2024: JFE Steel to invest $200 million in expanding motor lamination steel production at Kurashiki Works JFE Steel announced a major investment to expand its Kurashiki Works facility, increasing production capacity for high-grade electrical steel used in motor laminations for electric vehicles and industrial applications.

-

Q1 2024: ArcelorMittal signs supply agreement with major European EV manufacturer for motor lamination steel ArcelorMittal secured a multi-year contract to supply specialized electrical steel for motor laminations to a leading European electric vehicle manufacturer, strengthening its position in the EV materials supply chain.

-

Q2 2024: Baosteel unveils new ultra-thin silicon steel for high-speed motor lamination applications Baosteel launched a new ultra-thin silicon steel product line, engineered for use in high-speed motors and advanced electric vehicle applications, aiming to improve motor efficiency and reduce weight.

-

Q1 2024: Tempel Steel Company expands Chicago facility to boost EV motor lamination production Tempel Steel Company announced the expansion of its Chicago manufacturing facility, increasing its capacity to produce motor laminations for the rapidly growing electric vehicle market in North America.

-

Q2 2024: EuroGroup Laminations S.p.A. completes IPO on Euronext Milan, raising €400 million EuroGroup Laminations S.p.A., a leading manufacturer of motor laminations, successfully completed its initial public offering on Euronext Milan, raising €400 million to fund global expansion and R&D.

-

Q1 2024: Godrej & Boyce launches new range of high-efficiency motor laminations for renewable energy sector Godrej & Boyce introduced a new product line of high-efficiency motor laminations designed for use in wind turbines and solar power generation equipment, targeting the growing renewable energy market.

-

Q2 2024: EuroGroup Laminations signs strategic partnership with Siemens for advanced motor lamination technology EuroGroup Laminations entered into a strategic partnership with Siemens to co-develop advanced motor lamination technologies, focusing on improving efficiency and performance in electric mobility and industrial automation.

-

Q1 2024: Pitti Engineering Limited commissions new automated lamination stamping line in Hyderabad Pitti Engineering Limited commissioned a new automated stamping line at its Hyderabad facility, increasing production efficiency and capacity for motor laminations used in automotive and industrial motors.

-

Q2 2024: JFE Steel and Tata Steel announce joint venture to produce motor lamination steel in India JFE Steel and Tata Steel formed a joint venture to manufacture high-grade motor lamination steel in India, aiming to meet the rising demand from the country's electric vehicle and industrial sectors.

-

Q1 2024: Polaris Laser Laminations LLC opens new R&D center for advanced motor lamination prototyping Polaris Laser Laminations LLC opened a new research and development center dedicated to prototyping advanced motor laminations, supporting innovation in electric vehicle and industrial motor technologies.

Motor Lamination Market Segmentation Insights

Motor Lamination Application Outlook

Motor Lamination Material Type Outlook

Motor Lamination Process Outlook

Motor Lamination End Use Industry Outlook

Motor Lamination Regional Outlook

| Report Attribute/Metric |

Details |

| Market Size 2024 |

30.80 (USD Billion) |

| Market Size 2025 |

32.05 (USD Billion) |

| Market Size 2034 |

45.74 (USD Billion) |

| Compound Annual Growth Rate (CAGR) |

4.32% (2025 - 2034) |

| Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Base Year |

2024 |

| Market Forecast Period |

2025 - 2034 |

| Historical Data |

2019 - 2023 |

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

Littelfuse, Parker Hannifin, Weg, Honeywell, Mitsubishi Electric, Yaskawa Electric, Rockwell Automation, Eaton, General Electric, Emerson Electric, ABB, Schneider Electric, Toshiba, Siemens, Nidec Corporation |

| Segments Covered |

Application, Material Type, Process, End Use Industry, Regional |

| Key Market Opportunities |

Electrification of transportation, Renewable energy integration, Demand for energy-efficient motors, Advancements in manufacturing technologies, Growing electric vehicle market |

| Key Market Dynamics |

Rising electric vehicle adoption, Increasing energy efficiency demand, Technological advancements in manufacturing, Growing industrial automation, Stringent regulations on emissions |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ):

The Motor Lamination Market is expected to be valued at 45.74 USD Billion by 2034.

In 2024, the market size of the Motor Lamination Market was valued at 30.80 USD Billion.

The expected CAGR for the Motor Lamination Market from 2025 to 2034 is 4.32%.

The APAC region is projected to have the largest market size, estimated at 15.5 USD Billion in 2032.

The market size for Electric Motors application was valued at 10.5 USD Billion in 2023.

Key players in the Motor Lamination Market include Littelfuse, Parker Hannifin, Weg, and Honeywell.

The expected market value for the Transformers application is projected to reach 11.5 USD Billion by 2032.

North America is forecast to grow to 12.0 USD Billion by 2032 in the Motor Lamination Market.

The market size for Induction Motors application was valued at 3.96 USD Billion in 2023.

South America is expected to show modest growth with a market size of 2.8 USD Billion by 2032.