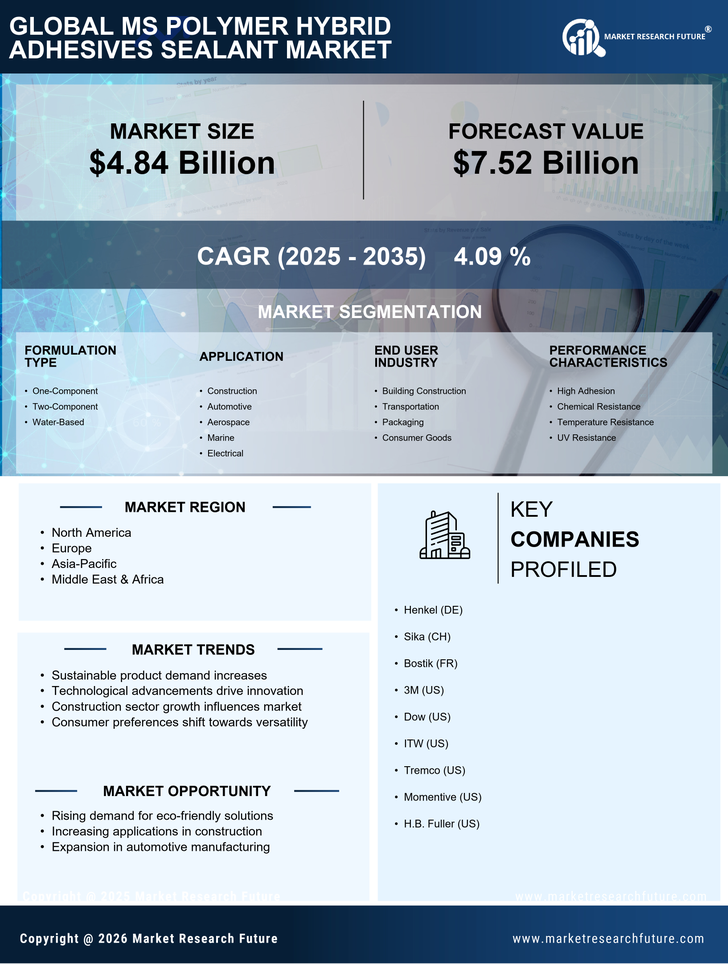

Rising Demand in Construction Sector

The construction sector is experiencing a notable surge in demand for MS Polymer Hybrid Adhesives Sealant Market products. This increase is primarily driven by the need for durable and flexible sealing solutions in various applications, including residential and commercial buildings. As construction activities ramp up, the market for these adhesives is projected to grow significantly. According to recent estimates, the construction industry is expected to expand at a compound annual growth rate of approximately 5% over the next few years. This growth is likely to bolster the demand for MS Polymer Hybrid Adhesives Sealant, as they offer superior adhesion properties and resistance to environmental factors, making them ideal for construction applications.

Environmental Regulations and Sustainability

The MS Polymer Hybrid Adhesives Sealant Market is increasingly influenced by stringent environmental regulations aimed at reducing volatile organic compounds (VOCs) in adhesives and sealants. As industries strive to comply with these regulations, there is a growing preference for eco-friendly products. MS Polymer adhesives are known for their low VOC emissions, which aligns with the sustainability goals of many manufacturers. This shift towards environmentally responsible products is expected to drive market growth, as companies seek to enhance their green credentials. Furthermore, the increasing consumer awareness regarding sustainability is likely to further propel the demand for MS Polymer Hybrid Adhesives Sealant, as end-users prefer products that contribute to a healthier environment.

Customization and Versatility of Applications

The versatility of MS Polymer Hybrid Adhesives Sealant Market products is a key driver of their adoption across various sectors. These adhesives can be tailored to meet specific performance requirements, making them suitable for a wide range of applications, from construction to automotive and beyond. The ability to customize formulations allows manufacturers to address unique challenges faced by different industries, thereby enhancing the appeal of MS Polymer adhesives. As industries continue to evolve and demand more specialized solutions, the market for these adhesives is likely to expand. This trend towards customization is expected to foster innovation and drive competition among manufacturers, ultimately benefiting end-users with a broader selection of high-performance adhesive products.

Growth in Automotive and Transportation Sectors

The automotive and transportation sectors are emerging as significant contributors to the MS Polymer Hybrid Adhesives Sealant Market. With the increasing focus on lightweight materials and fuel efficiency, manufacturers are seeking advanced adhesive solutions that can provide strong bonding while minimizing weight. MS Polymer adhesives are particularly suited for automotive applications due to their excellent mechanical properties and resistance to harsh environmental conditions. The automotive industry is projected to grow steadily, with an estimated CAGR of around 4% in the coming years. This growth is expected to drive the demand for MS Polymer Hybrid Adhesives Sealant, as they are increasingly utilized in vehicle assembly and repair processes.

Technological Innovations in Adhesive Formulations

Technological advancements in adhesive formulations are playing a crucial role in shaping the MS Polymer Hybrid Adhesives Sealant Market. Innovations such as the development of high-performance polymers and improved curing processes are enhancing the properties of these adhesives, making them more effective in various applications. For instance, the introduction of hybrid formulations that combine the best attributes of different materials is gaining traction. These innovations not only improve adhesion and flexibility but also expand the range of applications for MS Polymer adhesives. As manufacturers continue to invest in research and development, the market is likely to witness a proliferation of advanced adhesive solutions, catering to diverse industry needs.