Expansion of Renewable Energy Projects

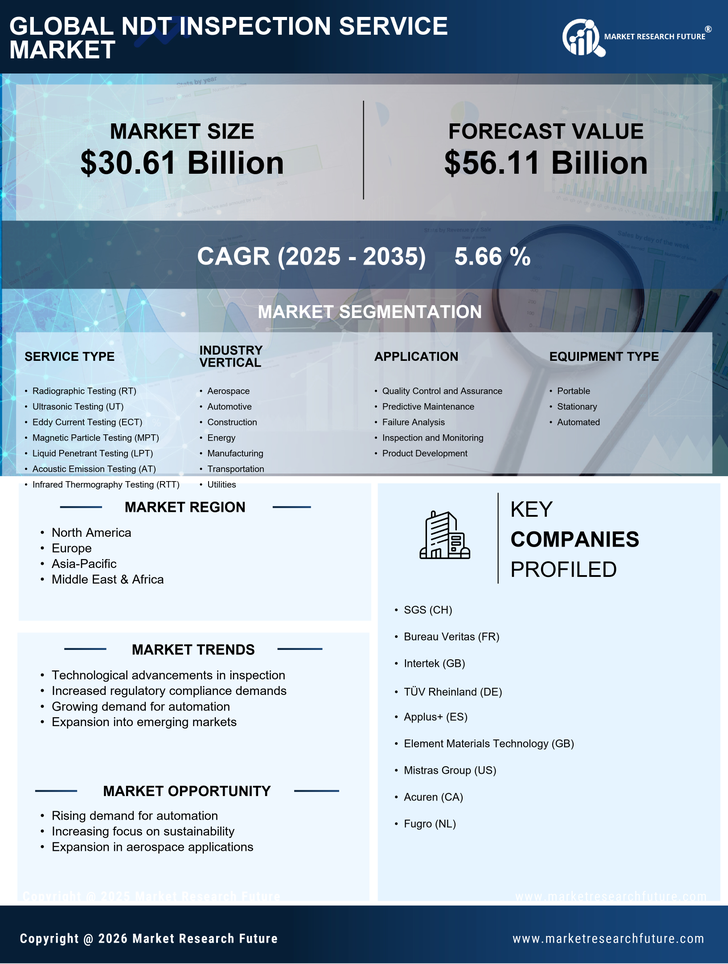

The NDT Inspection Service Market is witnessing growth due to the expansion of renewable energy projects, particularly in wind and solar energy sectors. As these industries grow, the need for reliable inspection services to ensure the integrity of components such as wind turbine blades and solar panels becomes critical. Non-destructive testing methods are essential for identifying material defects and ensuring the longevity of these renewable energy assets. The market is projected to expand as investments in renewable energy continue to rise, potentially increasing the demand for NDT services by 25% over the next few years. This trend reflects a broader commitment to sustainability and the need for rigorous inspection protocols in emerging energy sectors.

Growing Demand from the Aerospace Sector

The aerospace sector is a significant driver for the NDT Inspection Service Market, as it requires rigorous inspection processes to ensure the safety and reliability of aircraft. With the increasing production rates of commercial and military aircraft, the demand for NDT services is expected to rise. The need for non-destructive testing methods, such as eddy current and radiographic testing, is paramount in detecting flaws that could compromise aircraft integrity. Recent data suggests that the aerospace segment alone could account for nearly 30% of the NDT market by 2026. This growth is indicative of the sector's commitment to safety and quality assurance, further propelling the NDT Inspection Service Market.

Regulatory Compliance and Safety Standards

The NDT Inspection Service Market is heavily influenced by stringent regulatory compliance and safety standards across various sectors. Industries such as aerospace, oil and gas, and manufacturing are mandated to adhere to specific inspection protocols to ensure safety and reliability. Regulatory bodies often require regular inspections to prevent catastrophic failures, which drives the demand for NDT services. The market is projected to grow as companies invest in compliance to avoid penalties and enhance their operational integrity. In fact, the market could see an increase of approximately 15% over the next few years as organizations prioritize adherence to these regulations. This trend underscores the critical role of NDT services in maintaining safety and compliance.

Technological Advancements in NDT Inspection

The NDT Inspection Service Market is experiencing a surge in technological advancements that enhance inspection capabilities. Innovations such as automated ultrasonic testing and advanced imaging techniques are becoming increasingly prevalent. These technologies not only improve accuracy but also reduce inspection time, thereby increasing operational efficiency. The integration of artificial intelligence and machine learning into NDT processes is also noteworthy, as it allows for predictive maintenance and real-time data analysis. According to recent estimates, the adoption of these advanced technologies could potentially increase the market size by over 20% in the next five years. As industries seek to minimize downtime and enhance safety, the demand for technologically advanced NDT services is likely to grow significantly.

Increased Focus on Asset Integrity Management

The NDT Inspection Service Market is significantly influenced by the growing focus on asset integrity management across various industries. Companies are increasingly recognizing the importance of maintaining the integrity of their assets to prevent failures and reduce maintenance costs. This trend is particularly evident in sectors such as oil and gas, where the consequences of asset failure can be catastrophic. As a result, organizations are investing in NDT services to monitor the condition of their assets proactively. The market is expected to grow as more companies adopt comprehensive asset integrity management strategies, potentially leading to a 20% increase in demand for NDT services in the coming years. This shift highlights the critical role of NDT in ensuring operational efficiency and safety.