Rising Demand for Industrial Gases

The Non Cryogenic Air Separation Unit Market is significantly influenced by the rising demand for industrial gases across various sectors. Industries such as healthcare, food and beverage, and metallurgy are increasingly relying on oxygen and nitrogen for their operations. For instance, the healthcare sector utilizes oxygen for medical applications, while the food industry employs nitrogen for packaging and preservation. This growing demand is likely to propel the market for non cryogenic air separation units, as they provide a cost-effective solution for producing these gases on-site. Market data indicates that the industrial gases market is expected to reach USD 100 billion by 2026, further underscoring the potential growth opportunities for non cryogenic air separation units.

Diverse Applications Across Industries

The Non Cryogenic Air Separation Unit Market benefits from its diverse applications across multiple sectors. From chemical manufacturing to energy production, the versatility of non cryogenic air separation units makes them indispensable. For example, in the chemical industry, these units are utilized for the production of ammonia, while in the energy sector, they are employed for gasification processes. This broad applicability is likely to sustain market growth, as various industries seek reliable and efficient air separation solutions. The increasing need for customized solutions tailored to specific industrial requirements further enhances the market potential. As industries evolve, the demand for non cryogenic air separation units is expected to expand, driven by their adaptability.

Sustainability and Environmental Regulations

The Non Cryogenic Air Separation Unit Market is also shaped by the increasing emphasis on sustainability and stringent environmental regulations. Companies are under pressure to reduce their carbon footprint and comply with environmental standards. Non cryogenic air separation units offer a more environmentally friendly alternative to traditional methods, as they consume less energy and produce fewer emissions. This shift towards sustainable practices is likely to drive the adoption of non cryogenic technologies in various industries. Furthermore, government initiatives aimed at promoting cleaner technologies are expected to bolster the market. As organizations strive to meet regulatory requirements, the demand for efficient and eco-friendly air separation solutions is anticipated to rise.

Cost-Effectiveness and Operational Efficiency

The Non Cryogenic Air Separation Unit Market is characterized by the cost-effectiveness and operational efficiency of its technologies. Non cryogenic methods typically require lower capital investment compared to cryogenic systems, making them an attractive option for many businesses. Additionally, the operational costs associated with non cryogenic air separation units are generally lower due to reduced energy consumption. This financial advantage is likely to encourage more companies to adopt these systems, particularly in regions where budget constraints are prevalent. Market analysis suggests that the total cost of ownership for non cryogenic units is significantly lower over their lifecycle, which could lead to increased market penetration in various sectors.

Technological Advancements in Non Cryogenic Air Separation Units

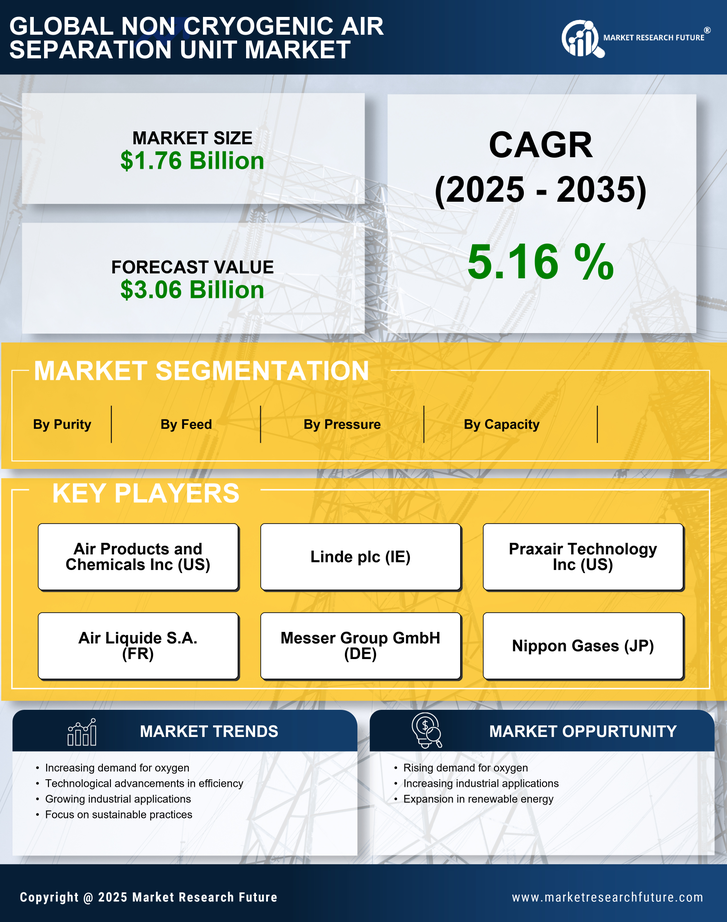

The Non Cryogenic Air Separation Unit Market is experiencing a surge in technological advancements that enhance efficiency and reduce operational costs. Innovations such as membrane separation and pressure swing adsorption are becoming increasingly prevalent. These technologies allow for the effective separation of oxygen and nitrogen at lower energy consumption levels. As a result, companies are likely to invest in these advanced systems to improve their production capabilities. The market for non cryogenic air separation units is projected to grow at a compound annual growth rate of approximately 5% over the next few years, driven by these technological improvements. Furthermore, the integration of automation and control systems is expected to streamline operations, thereby increasing the overall productivity of the units.