Advancements in Hypersonic Technologies

The Global High Temperature Material Testing Market for Aerospace and Hypersonic System Industry is significantly influenced by advancements in hypersonic technologies. As nations invest in developing hypersonic vehicles, the demand for materials that can endure extreme thermal and mechanical stresses is increasing. This necessitates rigorous testing protocols to ensure material integrity at high temperatures. The market's growth trajectory, with a forecasted value of 3750 USD Million by 2035, underscores the critical role of high temperature material testing in supporting these cutting-edge technologies, which may redefine aerospace capabilities and operational efficiencies.

Growing Demand for Aerospace Applications

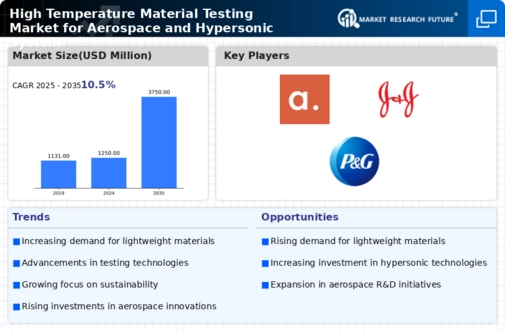

The Global High Temperature Material Testing Market for Aerospace and Hypersonic System Industry is witnessing a surge in demand driven by the increasing need for advanced materials in aerospace applications. As aircraft and spacecraft operate at elevated temperatures, the necessity for materials that can withstand extreme conditions becomes paramount. This trend is reflected in the projected market value of 1250 USD Million in 2024, with expectations to reach 3750 USD Million by 2035. The compound annual growth rate of 10.5% from 2025 to 2035 indicates a robust expansion, highlighting the industry's commitment to innovation and safety in high-performance environments.

Regulatory Compliance and Safety Standards

The Global High Temperature Material Testing Market for Aerospace and Hypersonic System Industry is also driven by stringent regulatory compliance and safety standards. Governments and regulatory bodies are imposing rigorous testing requirements to ensure that materials used in aerospace applications meet safety and performance benchmarks. This trend compels manufacturers to invest in high temperature material testing to comply with evolving regulations. As the market evolves, the emphasis on safety and reliability is likely to propel growth, contributing to the anticipated market value of 1250 USD Million in 2024 and a substantial increase by 2035.

Emergence of New Materials and Technologies

The Global High Temperature Material Testing Market for Aerospace and Hypersonic System Industry is characterized by the emergence of new materials and technologies. Innovations in ceramics, composites, and metal alloys are reshaping the landscape of high-temperature materials, offering enhanced performance and durability. These advancements necessitate comprehensive testing to validate material properties under extreme conditions. The anticipated growth of the market, reaching 3750 USD Million by 2035, indicates a strong demand for testing services that can support the integration of these novel materials into aerospace applications.

Increased Investment in Research and Development

The Global High Temperature Material Testing Market for Aerospace and Hypersonic System Industry benefits from increased investment in research and development. As aerospace companies strive to innovate and enhance material performance, R&D initiatives are crucial for developing new high-temperature materials. This investment not only fosters technological advancements but also ensures that materials can withstand the demanding conditions of hypersonic flight. The projected CAGR of 10.5% from 2025 to 2035 reflects the industry's commitment to advancing material science, which is essential for maintaining competitive advantages in the global aerospace sector.