Increased Focus on Grid Stability

The increased focus on grid stability is a pivotal driver for the Oil Immersed Shunt Reactor Market. As electrical grids become more complex due to the integration of diverse energy sources, maintaining stability has become a critical concern for utilities. Oil immersed shunt reactors are instrumental in providing reactive power support and voltage regulation, which are essential for preventing outages and ensuring a reliable power supply. Recent studies indicate that the frequency of grid disturbances has risen, prompting utilities to invest in solutions that enhance grid resilience. This trend is expected to drive the demand for oil immersed shunt reactors, as they are recognized for their effectiveness in stabilizing voltage levels and improving overall grid performance. Consequently, the market is likely to experience growth as utilities prioritize investments in technologies that bolster grid stability.

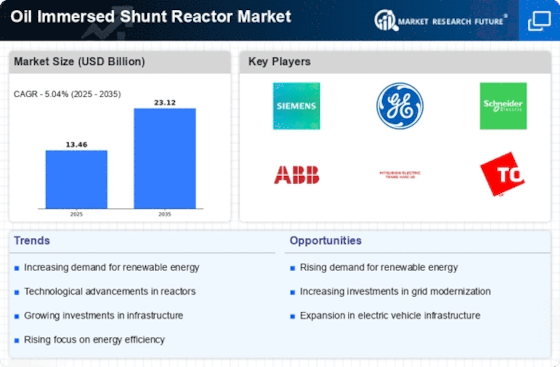

Rising Demand for Renewable Energy

The increasing emphasis on renewable energy sources is driving the Oil Immersed Shunt Reactor Market. As countries strive to meet their energy needs sustainably, the integration of renewable energy into existing grids becomes paramount. Oil immersed shunt reactors play a crucial role in stabilizing voltage levels and managing reactive power in these systems. According to recent data, the renewable energy sector is projected to grow at a compound annual growth rate of over 8% in the coming years. This growth necessitates the deployment of efficient electrical components, including oil immersed shunt reactors, to ensure grid reliability and performance. Consequently, the demand for these reactors is likely to surge as utilities and energy providers invest in modernizing their infrastructure to accommodate renewable energy sources.

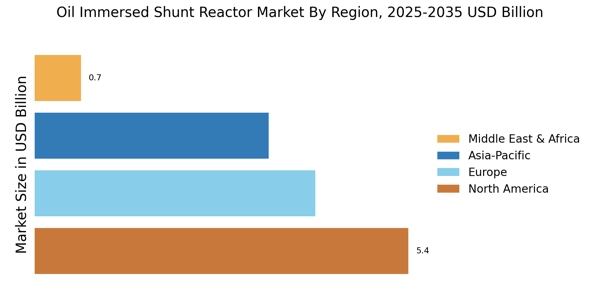

Infrastructure Development Initiatives

Infrastructure development initiatives across various regions are significantly influencing the Oil Immersed Shunt Reactor Market. Governments are increasingly investing in upgrading and expanding electrical grids to enhance reliability and efficiency. This trend is particularly evident in emerging economies, where rapid urbanization and industrialization are creating a pressing need for robust electrical infrastructure. The International Energy Agency has indicated that investments in grid infrastructure could reach trillions of dollars over the next decade. As these initiatives unfold, the demand for oil immersed shunt reactors is expected to rise, as they are essential for managing voltage fluctuations and ensuring the stability of the electrical supply. This growing focus on infrastructure development is likely to create substantial opportunities for manufacturers and suppliers within the market.

Technological Innovations in Reactor Design

Technological innovations in reactor design are reshaping the Oil Immersed Shunt Reactor Market. Advances in materials science and engineering have led to the development of more efficient and reliable reactors. These innovations not only enhance performance but also reduce maintenance costs and improve the overall lifespan of the reactors. For instance, the introduction of advanced insulation materials and cooling techniques has resulted in reactors that can operate under more demanding conditions. Market data suggests that the adoption of these advanced designs is increasing, with a notable rise in the installation of high-capacity oil immersed shunt reactors in substations. As utilities seek to optimize their operations and reduce downtime, the demand for technologically advanced reactors is likely to grow, further propelling the market forward.

Regulatory Support for Electrical Infrastructure

Regulatory support for electrical infrastructure is significantly impacting the Oil Immersed Shunt Reactor Market. Governments and regulatory bodies are increasingly recognizing the importance of reliable electrical systems and are implementing policies that encourage investment in grid modernization. These regulations often include incentives for utilities to adopt advanced technologies, including oil immersed shunt reactors, which are essential for managing reactive power and ensuring voltage stability. Recent regulatory frameworks have emphasized the need for utilities to enhance their infrastructure to meet growing energy demands and environmental standards. As a result, the market for oil immersed shunt reactors is likely to benefit from this supportive regulatory environment, as utilities seek to comply with new standards and improve their operational efficiency.