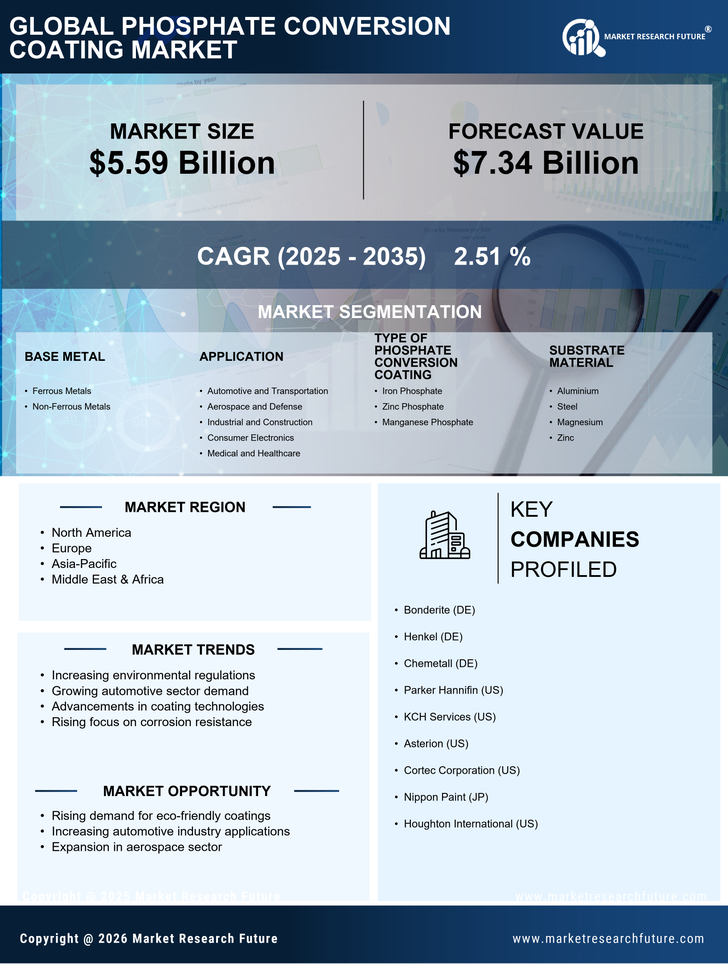

Increasing Regulatory Standards

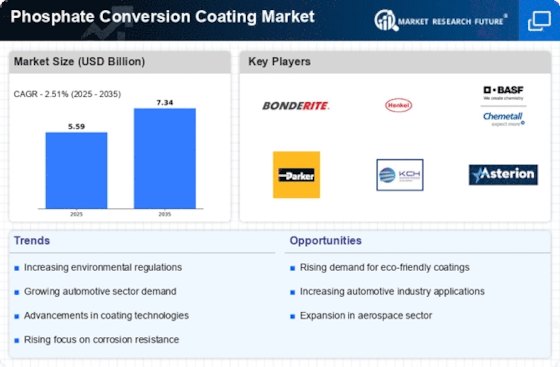

The Phosphate Conversion Coating Market is significantly influenced by increasing regulatory standards aimed at enhancing product safety and environmental protection. Governments and regulatory bodies are implementing stringent guidelines regarding the use of coatings in various industries, including automotive and aerospace. Compliance with these regulations necessitates the adoption of phosphate conversion coatings, which are recognized for their effectiveness in providing corrosion resistance and improving adhesion. In recent years, the market has seen a shift towards coatings that meet these regulatory requirements, with a projected growth rate of 5% annually. This trend indicates that manufacturers are prioritizing compliance as a key factor in their coating selection process, thereby driving demand for phosphate conversion coatings.

Rising Demand in Automotive Sector

The Phosphate Conversion Coating Market is experiencing a notable surge in demand, particularly from the automotive sector. As manufacturers increasingly prioritize corrosion resistance and surface protection, phosphate coatings are becoming essential in vehicle production. The automotive industry is projected to account for a significant share of the market, driven by the need for enhanced durability and aesthetic appeal. In 2023, the automotive segment represented approximately 35% of the overall market, indicating a robust growth trajectory. This trend is likely to continue as electric vehicles gain traction, necessitating advanced coating solutions to protect against environmental factors. Furthermore, the shift towards lightweight materials in automotive design further amplifies the need for effective phosphate conversion coatings, thereby propelling market growth.

Expansion in Aerospace Applications

The Phosphate Conversion Coating Market is witnessing an expansion in its applications within the aerospace sector. The stringent requirements for corrosion resistance and weight reduction in aircraft manufacturing have led to an increased adoption of phosphate coatings. These coatings provide a reliable solution for protecting aluminum and other metal substrates used in aircraft components. In recent years, the aerospace segment has shown a growth rate of approximately 6% annually, reflecting the industry's commitment to enhancing performance and safety. As the demand for fuel-efficient aircraft rises, the need for advanced surface treatments, including phosphate conversion coatings, is expected to grow. This trend underscores the critical role of phosphate coatings in meeting the rigorous standards of the aerospace industry.

Technological Innovations in Coating Processes

Technological innovations are playing a pivotal role in shaping the Phosphate Conversion Coating Market. Advances in coating processes, such as the development of eco-friendly phosphating solutions, are gaining traction among manufacturers. These innovations not only enhance the performance of coatings but also align with sustainability goals. The introduction of automated application techniques has improved efficiency and consistency in coating applications, further driving market growth. In 2023, the market for advanced phosphating technologies was valued at approximately USD 1.2 billion, indicating a strong demand for innovative solutions. As manufacturers seek to optimize production processes and reduce environmental impact, the adoption of these technologies is likely to accelerate, positioning the phosphate conversion coating market for sustained growth.

Growth in Construction and Infrastructure Development

The Phosphate Conversion Coating Market is benefiting from the growth in construction and infrastructure development. As urbanization accelerates, the demand for durable and corrosion-resistant materials in construction applications is on the rise. Phosphate conversion coatings are increasingly utilized in the protection of steel and metal components used in buildings, bridges, and other infrastructure projects. The construction sector is expected to witness a growth rate of approximately 4% annually, contributing to the overall expansion of the phosphate coating market. This growth is further supported by the increasing focus on sustainable building practices, where phosphate coatings offer an effective solution for enhancing the longevity of structures. As infrastructure projects continue to proliferate, the demand for phosphate conversion coatings is likely to increase.