Growth in Manufacturing Sector

The manufacturing sector plays a pivotal role in the expansion of the Plastic Strapping Material Market. As production activities ramp up across various industries, the need for effective strapping solutions becomes paramount. Plastic strapping materials are essential for bundling and securing products, ensuring they remain intact during storage and transportation. In recent years, the manufacturing sector has experienced a resurgence, with many regions reporting increased output. This growth is likely to drive demand for plastic strapping materials, as manufacturers seek to optimize their packaging processes. The industry is expected to benefit from this trend, with projections indicating a steady increase in market size as manufacturers prioritize efficiency and product safety.

Innovations in Material Technology

Technological advancements in material science are significantly influencing the Plastic Strapping Material Market. Innovations such as the development of high-strength, lightweight plastic strapping materials are enhancing the performance and efficiency of packaging solutions. These advancements not only improve the durability of strapping but also reduce material costs, making them more appealing to businesses. As companies increasingly seek sustainable and cost-effective packaging options, the adoption of these innovative materials is likely to rise. The market is expected to see a shift towards more advanced strapping solutions, with manufacturers investing in research and development to create products that meet evolving consumer demands. This trend may lead to a more competitive landscape within the industry.

Rising Demand for E-commerce Packaging

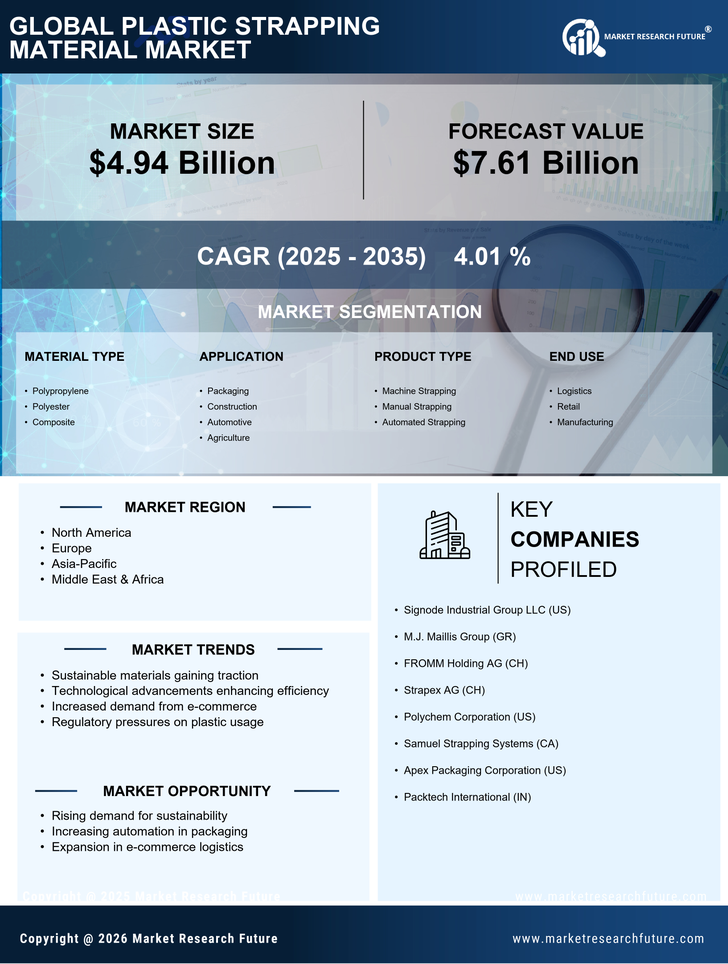

The surge in e-commerce activities has led to an increased demand for efficient packaging solutions, including plastic strapping materials. As online shopping continues to expand, businesses require reliable and durable packaging to ensure product safety during transit. The Plastic Strapping Material Market is witnessing a notable uptick in demand, driven by the need for secure packaging that can withstand the rigors of shipping. In 2025, the market is projected to grow significantly, with estimates suggesting a compound annual growth rate of around 5% over the next few years. This trend indicates that companies are increasingly adopting plastic strapping materials to enhance their packaging processes, thereby contributing to the overall growth of the industry.

Increased Focus on Supply Chain Efficiency

The emphasis on supply chain optimization is driving the demand for plastic strapping materials in various industries. Companies are increasingly recognizing the importance of efficient packaging solutions to streamline their logistics and reduce operational costs. The Plastic Strapping Material Market is benefiting from this trend, as businesses seek to enhance their packaging processes to improve overall supply chain performance. By utilizing plastic strapping materials, companies can ensure that their products are securely packaged, minimizing the risk of damage during transit. This focus on efficiency is likely to propel market growth, as organizations invest in better packaging solutions to meet the demands of a competitive marketplace.

Regulatory Support for Sustainable Practices

Regulatory frameworks promoting sustainable practices are influencing the Plastic Strapping Material Market. Governments are increasingly implementing policies that encourage the use of eco-friendly packaging materials, including recyclable plastic strapping solutions. This regulatory support is likely to drive innovation within the industry, as manufacturers seek to comply with environmental standards while meeting market demands. The shift towards sustainability is expected to create new opportunities for growth, as businesses look for compliant packaging solutions that align with their corporate social responsibility goals. As a result, the market may witness a rise in the adoption of sustainable plastic strapping materials, contributing to a more environmentally conscious industry.