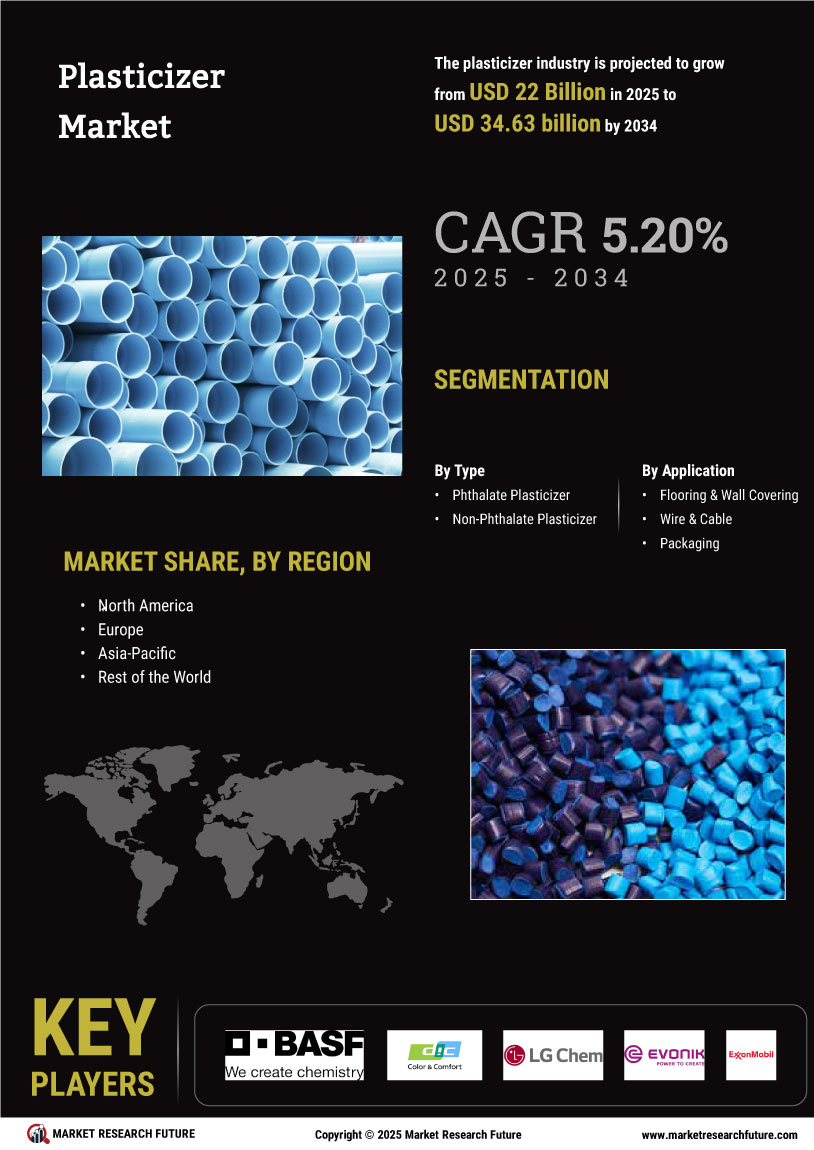

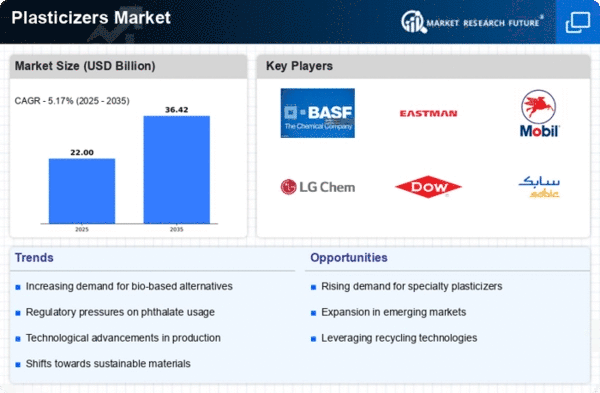

The Plasticizers Market is currently characterized by a dynamic competitive landscape, driven by increasing demand for flexible materials across various industries, including construction, automotive, and consumer goods. Key players such as BASF SE (DE), Eastman Chemical Company (US), and DOW Inc. (US) are strategically positioned to leverage their extensive product portfolios and innovative capabilities. BASF SE (DE) focuses on sustainable solutions, emphasizing bio-based plasticizers, while Eastman Chemical Company (US) has been enhancing its production capabilities to meet rising global demand. DOW Inc. (US) is actively pursuing digital transformation initiatives to optimize its operations and improve customer engagement, collectively shaping a competitive environment that prioritizes innovation and sustainability.

In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and enhance supply chain efficiency. The market structure appears moderately fragmented, with several players vying for market share. However, the collective influence of major companies like SABIC (SA) and ExxonMobil Chemical (US) is notable, as they continue to expand their global footprint and invest in advanced manufacturing technologies.

In November 2025, SABIC (SA) announced a strategic partnership with a leading technology firm to develop next-generation plasticizers that are more environmentally friendly. This collaboration is expected to enhance SABIC's product offerings and align with the growing regulatory pressures for sustainable materials. The strategic importance of this move lies in its potential to position SABIC as a leader in sustainable plasticizer solutions, catering to an increasingly eco-conscious market.

In October 2025, Eastman Chemical Company (US) unveiled a new production facility in Europe aimed at increasing its capacity for non-phthalate plasticizers. This expansion is significant as it not only addresses the rising demand for safer alternatives but also strengthens Eastman's competitive edge in the European market, where regulatory frameworks are becoming more stringent.

In September 2025, DOW Inc. (US) launched a digital platform designed to streamline customer interactions and enhance supply chain transparency. This initiative reflects a broader trend towards digitalization within the industry, allowing DOW to respond more effectively to customer needs and market fluctuations. The strategic importance of this platform lies in its potential to foster customer loyalty and improve operational efficiency.

As of December 2025, the competitive trends in the Plasticizers Market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are becoming more prevalent, enabling companies to pool resources and expertise to innovate more rapidly. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability, as companies strive to meet the demands of a rapidly changing market.

Leave a Comment