Top Industry Leaders in the Polyamide 12 Market

Polyamide 12 Market

Polyamide 12 (PA 12), also known as Nylon 12, is a high-performance engineering plastic renowned for its exceptional strength, chemical resistance, and thermal stability. Its versatility fuels demand across diverse industries, primarily automotive, oil & gas, industrial coatings, and consumer goods.

Strategies for Market Share:

-

Product Differentiation and Innovation: Leading players invest heavily in research and development, aiming to introduce novel Polyamide 12 grades with improved properties like enhanced flame retardancy, lightweighting capabilities, and biodegradability. -

Vertical Integration: Expanding into upstream segments like monomer production helps secure raw material supply and cost control. Arkema's acquisition of French company Technip Energies' polyamide 12 business in 2023 exemplifies this strategy. -

Geographic Expansion: Targeting high-growth regions like Asia Pacific and Latin America through greenfield investments or strategic partnerships is crucial for capturing new markets. Evonik's joint venture with China's Zhejiang Huafu Chemical Group for PA 12 production in China is a prime example. -

Sustainability Focus: Responding to growing environmental concerns, companies are developing bio-based or recycled Polyamide 12 grades, attracting eco-conscious consumers and brands. Solvay's PA 12 bio-polymer portfolio under the Technyl 4EARTH brand is a noteworthy initiative.

Key Factors Influencing Market Share:

-

Production Capacity and Efficiency: Companies with efficient production facilities and consistent supply chains hold an edge in meeting customer demands. Evonik's expansion of its PA 12 production capacity in Marl, Germany, in October 2023, strengthens its position. -

Pricing Strategies: Balancing competitive pricing with profitability is crucial. BASF's price increase for PA 12 in September 2023 highlights the ongoing cost pressures in the market. -

Customer Relationships and Partnerships: Building strong relationships with key customers in target industries, like automotive OEMs and medical device manufacturers, can secure long-term contracts and market share. -

Regulatory Landscape: Stringent regulations on chemical usage and sustainability can impact production costs and product offerings. DuPont's efforts in developing compliant and safe PA 12 grades for medical applications showcase adaptation to regulatory trends.

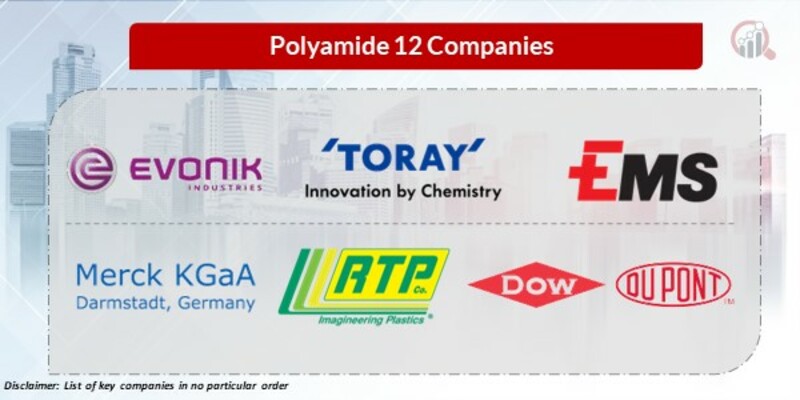

Key Companies in the Polyamide 12 market include

- Evonik Industries AG (Germany)

- Toray Industries Inc (Japan)

- EMS-Chemie Holding AG (Switzerland)

- Merck KGaA (Germany)

- RTP Company (US)

- DowDuPont (US)

- Arkema SA (France)

Recent Developments

October 2021: Evonik has begun to supply subsequent ecological polyamide 12 molding materials to its clients. The business has revealed that some commercial VESTAMID products may now be manufactured using renewable energy sources at Evonik's Marl Chemical Park in Germany. It has a better eco-balance: its greenhouse gas emissions are reduced by 40%, while the use of land and consumption of water is reduced by more than 99%.

January 2021: Ineos Styrolution has announced the preliminary findings of the PolySLS initiative, which is focused on developing a revolutionary saving energy styrenics-based substance for additive production, often known as 3D printing.

June 2020: Mitsubishi Chemical Corporation (MCC) and AMP, an emerging German biomaterials start-up, have engaged in a select joint research and commercial business contract on PBT powder material for commercial 3D printing in June 2020. This collaboration allows MCC and AMP to extend their 3D printing product line significantly.

Evonik Industries expanded its polyamide 12 production facility located in Marl, Germany, during the year 2011. The construction should boost production capacity within this facility by almost one half thus satisfying rising demand among different sectors for high-performance polymers. It is expected that the new technological line will be put into operation by 2022, having been created in accordance with the most modern principles of production technology so as to increase efficiency and environmental friendliness.